![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

kuanyuan

Model:

kuanyuan

![]() NET Weight:

4 tons

NET Weight:

4 tons

![]() Diameter:

30-38

Diameter:

30-38

![]() Gauge:

12G-24G

Gauge:

12G-24G

![]() Feeder:

36F/54F

Feeder:

36F/54F

![]() Certification:

CE, ISO

Certification:

CE, ISO

![]() Applicable Yarn Material:

Bottoming shirts, pajamas, bath towels, towels, sweater linings, etc

Applicable Yarn Material:

Bottoming shirts, pajamas, bath towels, towels, sweater linings, etc

![]() RPM:

14-18RPM

RPM:

14-18RPM

![]() Wooden Box Size:

2.25M*2.23M*2.25M

Wooden Box Size:

2.25M*2.23M*2.25M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

The Computerized Terry Jacquard Circular Knitting Machine is an advanced textile manufacturing solution designed for the high-efficiency production of terry jacquard fabrics. Combining sophisticated computerized controls with state-of-the-art knitting technologies, this machine enables the creation of intricate, high-quality designs on terry fabrics used across various apparel and home textile applications.

Computerized Control System

Integrated with intelligent computer controls for precise pattern management, real-time monitoring, and efficient production control.

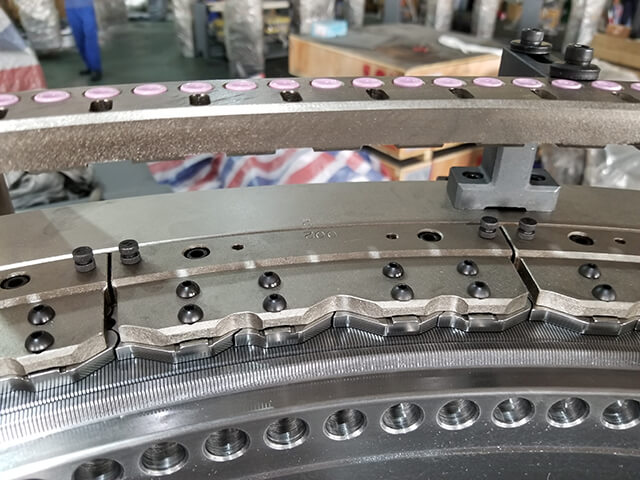

Jacquard Knitting Technology

Capable of producing highly detailed, complex patterns with precision and repeatability using jacquard mechanisms.

Circular Knitting Mechanism

Enables continuous, seamless fabric formation for increased production efficiency and superior fabric consistency.

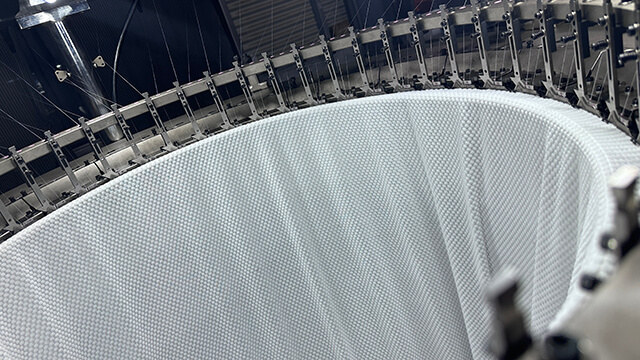

Terry Loop Formation

Specialized for terry knitting, allowing the formation of plush loops for enhanced thickness, comfort, and absorbency.

Automatic Yarn Feeding System

Ensures smooth yarn delivery, reduces operator intervention, and minimizes production downtime.

Routine Maintenance

Follow manufacturer-recommended maintenance schedules to maintain peak performance and extend machine life.

Operator Safety

Adhere to safety protocols and ensure all operators use appropriate protective gear.

Training

Only trained personnel should operate the machine. Comprehensive training is essential for efficiency and safety.

Stable Power Supply

Ensure uninterrupted, stable power to prevent production halts and data loss.

Environmental Conditions

Install in a clean, dry, and well-ventilated environment, away from excessive dust, moisture, and extreme temperatures.

Supports Reverse (Polar) Terry and Velour (Ordinary Terry) configurations with jacquard integration.

Designed for operator convenience and ease of maintenance.

Optional multi-language computerized interface for international usability.

Ideal for producing:

Bottoming shirts

Pajamas

Bath towels & towels

Sweater linings

Other plush and patterned terry products

| Model | Diameter | Gauge | Feeder | Application |

|---|---|---|---|---|

|

|

30”–38” | 12G–24G | 36F / 54F | Bottoming shirts, pajamas, towels, bath towels, linings, etc. |

Note: Final RPM varies based on yarn type, gauge, and knitting conditions.

| Diameter | Gauge | Feeder | Recommended RPM |

|---|---|---|---|

| 30” | 12G–24G | 42F / 36F | 14–18 RPM |

| 34” | 12G–24G | 48F / 42F | 14–18 RPM |

| Model | Diameter | Net Weight | Gross Weight | Packaging Dimensions (L×W×H) |

|---|---|---|---|---|

| kunyuan | 34” | Approx. 2.0T | Approx. 2.5T | 2.25m × 2.23m × 2.25m |

Key Functions:

1. Pattern Creation: The machine's computerized control system enables the creation of intricate patterns and designs on the fabric, allowing for customization and versatility.

2. High-Speed Production: With its advanced automation features, the machine can produce fabrics at high speeds, ensuring efficient and timely production.

3. Quality Control: The computerized control system ensures consistent stitch density, tension, and pattern alignment, resulting in high-quality and uniform fabrics.

4. Efficient Material Usage: The circular knitting technique employed by the machine minimizes material waste, maximizing cost-effectiveness and sustainability.In conclusion, the Computerized Terry Jacquard Circular Knitting Machine combines advanced technology with traditional knitting techniques to deliver superior-quality terry jacquard fabrics.

Its innovative features, customizable designs, and efficient production capabilities make it an essential tool for textile manufacturers in various industries.

Applications:

The Computerized Terry Jacquard Circular Knitting Machine finds extensive applications in the textile industry. It is suitable for the production of various textiles, including towels, bathrobes, blankets, upholstery fabrics, and fashion garments. The machine's flexibility allows for customization, making it ideal for catering to diverse customer demands.

It is particularly suitable for the production of terry jacquard fabrics used in:

1. Apparel: It creates luxurious and textured fabrics for clothing items such as bathrobes, towels, sportswear, and activewear.

2. Home Textiles: The machine produces high-quality terry jacquard fabrics for bed sheets, blankets, curtains, and upholstery.

3. Automotive Interiors:

The Three Thread Fleece Circular Knitting Machine is a highly versatile and efficient machine used in the textile industry. With its advanced technology and design, this machine offers numerous application...

Introduction to High Pile Jacquard Circular Knitting MachineHigh Pile Jacquard Circular Knitting Machine is a specialized machinery used for creating high pile fabrics with intricate designs. It combines t...

The Computerized Terry Jacquard Circular Knitting Machine delivers precise patterns, stable performance, and high efficiency. It’s user-friendly and ideal for producing complex terry fabrics with consistent quality.2025-07-11

It produces intricate jacquard patterns and soft terry fabrics with consistent texture and excellent durability. The computerized control system ensures accurate design execution, stable operation, and high production efficiency. Reliable and easy to maintain,2025-07-16