![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

Model:

![]() NET Weight:

NET Weight:

![]() Diameter:

Diameter:

![]() Gauge:

16G-26G

Gauge:

16G-26G

![]() Feeder:

12F-34F

Feeder:

12F-34F

![]() Certification:

Certification:

![]() Applicable Yarn Material:

Applicable Yarn Material:

![]() RPM:

Cylinder cutter type. Short loop usually use cutter and hook separately. long loop usually use cutter&hook in one.

RPM:

Cylinder cutter type. Short loop usually use cutter and hook separately. long loop usually use cutter&hook in one.

![]() Wooden Box Size:

2.25M*2.23M*2.25M

Wooden Box Size:

2.25M*2.23M*2.25M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

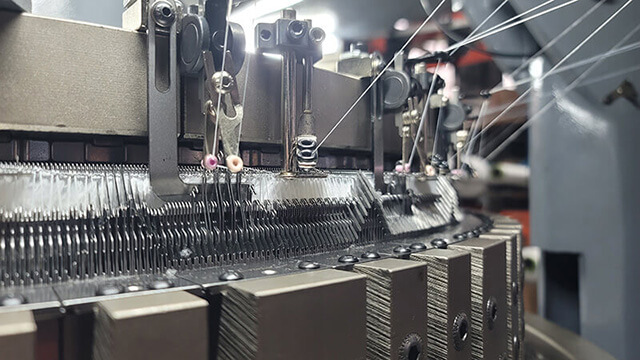

High Pile Cutting Circular Knitting Machine represents the pinnacle of textile manufacturing technology, designed to produce premium high-pile fabrics with exceptional precision and efficiency. Combining innovative knitting mechanisms with a state-of-the-art cutting system, this machine meets the rigorous demands of contemporary textile production, ensuring consistent quality and versatility.

High-Precision Knitting

Utilizes advanced knitting technology to deliver consistent pile height and superior fabric quality, minimizing variations and defects.

Efficient Cutting System

Features a high-speed cutting mechanism that precisely trims fabric piles to desired lengths, ensuring uniform pile height and a neat finish.

Flexible Pile Height Adjustment

Easily adjustable settings allow customization of pile height, accommodating a wide range of design specifications and customer preferences.

Enhanced Control System

Equipped with a user-friendly, programmable interface enabling operators to monitor and control production parameters for optimal efficiency.

Smooth Fabric Handling

Integrated fabric delivery system maintains tension consistency and prevents damage, ensuring smooth continuous operation.

Available with dial cutter or cylinder cutter types.

Designed as a modern alternative to traditional warp knitting machines.

Cam system convertible to interlock machine as per requirements.

Optional settings for different pile heights to cater to diverse fabric styles.

Ideal for applications in clothing, toys, and home textiles.

| Model | Diameter | Gauge | Feeder Range | Remark |

|---|---|---|---|---|

| HMC | 18’’–48’’ | 16G–26G | 12F–34F | Cylinder cutter type; short loops use separate cutter and hook; long loops use combined cutter & hook. |

| HMD | — | 16G–22G | 30F–72F | Dial cutter type; high density fabrics with short loop limitations. Common size: 38" diameter, 22G, 60 feeders. |

| Parameter | Value |

|---|---|

| Gray Fabric Width | 220 cm – 230 cm |

| Finished Fabric Width | 150 cm – 220 cm |

| Raw Materials & GSM |

100D ground yarn + 150D fur yarn, GSM < 350 g/m² 150D ground yarn + 150D fur yarn, GSM > 350 g/m² |

| Production Quantity | 350 kg to 400 kg per 24 hours |

| Model | Diameter | Net Weight Approx. | Gross Weight Approx. | Wooden Box Size (L×W×H) |

|---|---|---|---|---|

| HM | 34’’ | 3.0 T | 3.5 T | 2.25 m × 2.23 m × 2.25 m |

Main Functions:

1. High-Pile Fabric Production: The machine excels in producing high-pile fabrics with uniform pile height and excellent softness, ideal for creating luxurious and cozy textile products.

2. Accurate Cutting: The cutting system precisely trims the fabric pile to achieve the desired length, ensuring consistent and neat finished products.

3. Customizable Designs: The machine allows for customization of pile height, enabling the production of fabrics with various textures and appearances to meet different design needs.

4. Efficient Production: With its advanced technology and user-friendly controls, the machine ensures efficient and reliable production, maximizing productivity and reducing production costs.In conclusion, the High Pile Cutting Circular Knitting Machine is a cutting-edge textile manufacturing equipment that offers precise fabric production, efficient cutting, and customizable design options. Its applications are extensive in the textile industry, providing high-quality fabrics for various products.+

Application Fields:

The High Pile Cutting Circular Knitting Machine is widely used in the textile industry for manufacturing a wide range of products, including plush toys, home textiles, upholstery fabrics, blankets, and garments. Its versatility and precision make it suitable for both small-scale production and large-scale manufacturing operations.

Important Considerations:

1. Operator Training: It is essential for operators to receive proper training on machine operation, maintenance, and safety protocols to ensure smooth operation and prevent accidents.

2. Regular Maintenance: Routine inspection and maintenance are crucial to keep the machine in peak condition and extend its service life.

3. Material Selection: High-quality raw materials should be used to ensure the production of premium high-pile fabrics with excellent softness, durability, and aesthetic appeal..

The High Pile Cutting Circular Knitting Machine performs efficiently with precise cutting and consistent pile quality. It is easy to operate and maintain, making it ideal for producing soft, high-quality knitted fabrics.2025-07-11

The High Pile Jacquard Circular Knitting Machine offers excellent production efficiency with fast knitting speeds and minimal downtime. Its advanced design ensures consistent high-quality pile fabrics, boosting overall productivity while maintaining precision and durability in demanding manufacturin2025-07-11