![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

kuanyuan

Model:

kuanyuan

![]() NET Weight:

2.5 tons

NET Weight:

2.5 tons

![]() Diameter:

1.75m

Diameter:

1.75m

![]() Gauge:

26 needles for upper needles, 13 needles for lower needles

Gauge:

26 needles for upper needles, 13 needles for lower needles

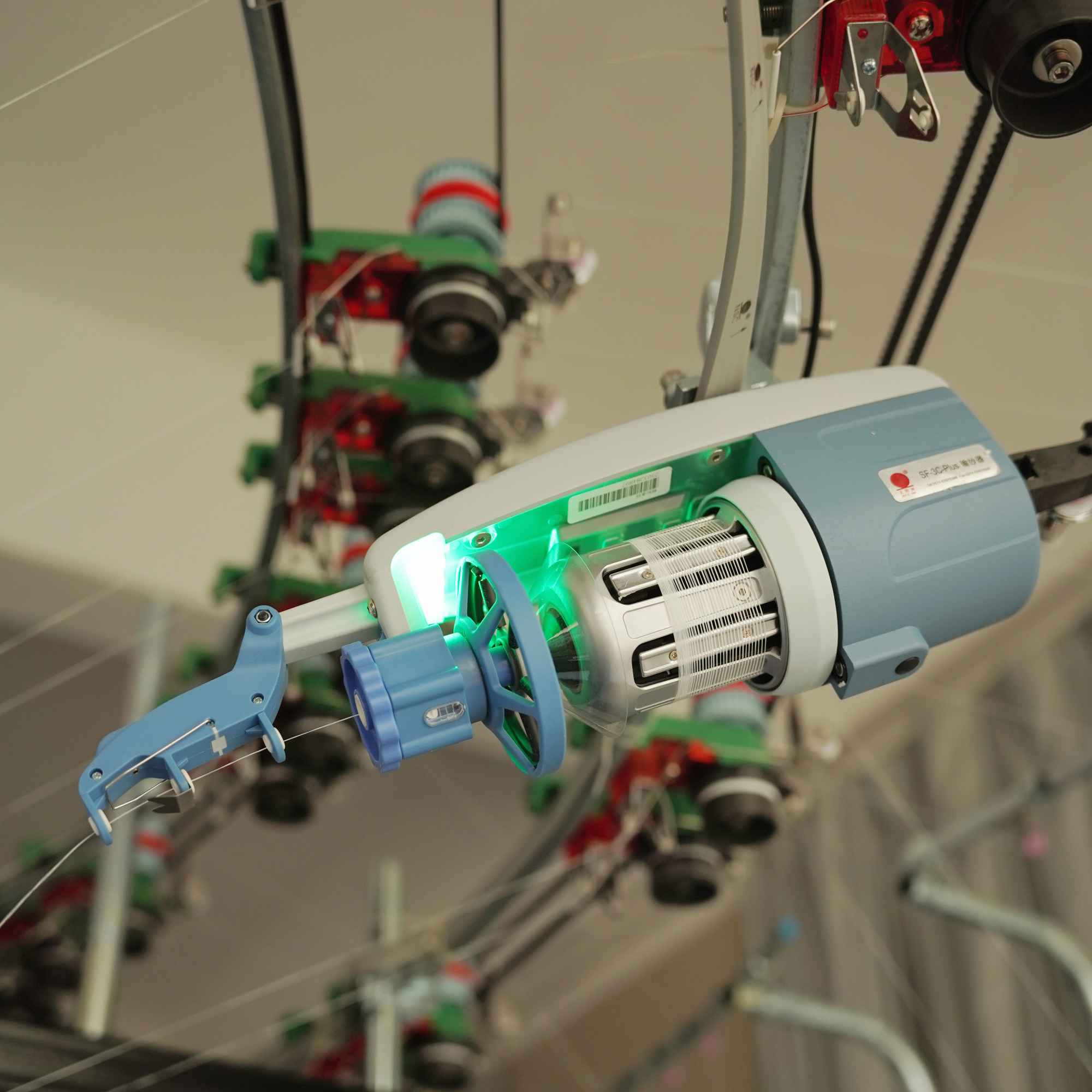

![]() Feeder:

18

Feeder:

18

![]() Certification:

ISO,CE

Certification:

ISO,CE

![]() Applicable Yarn Material:

Sun State

Applicable Yarn Material:

Sun State

![]() RPM:

13th

RPM:

13th

![]() Wooden Box Size:

2.25m*3m

Wooden Box Size:

2.25m*3m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

Hair Raising Machine Function and Equipment Features

The Hair Raising Machine is a specialized textile finishing machine used to raise or lift the surface fibers of fabrics to create a soft, warm, and fluffy texture. This process, often referred to as "raising" or "napping," enhances the tactile quality, insulation, and appearance of textiles such as wool, cotton, or synthetic blends.

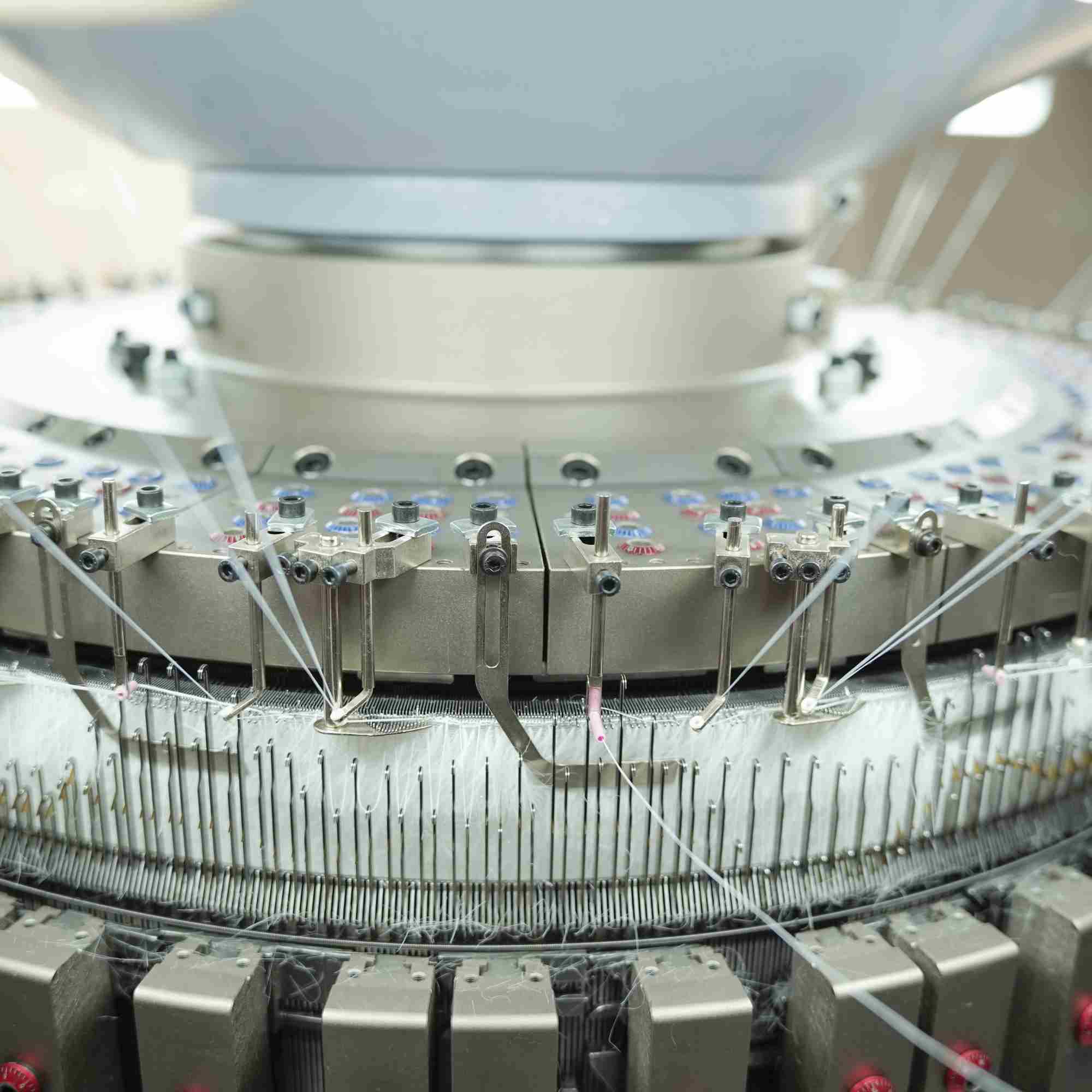

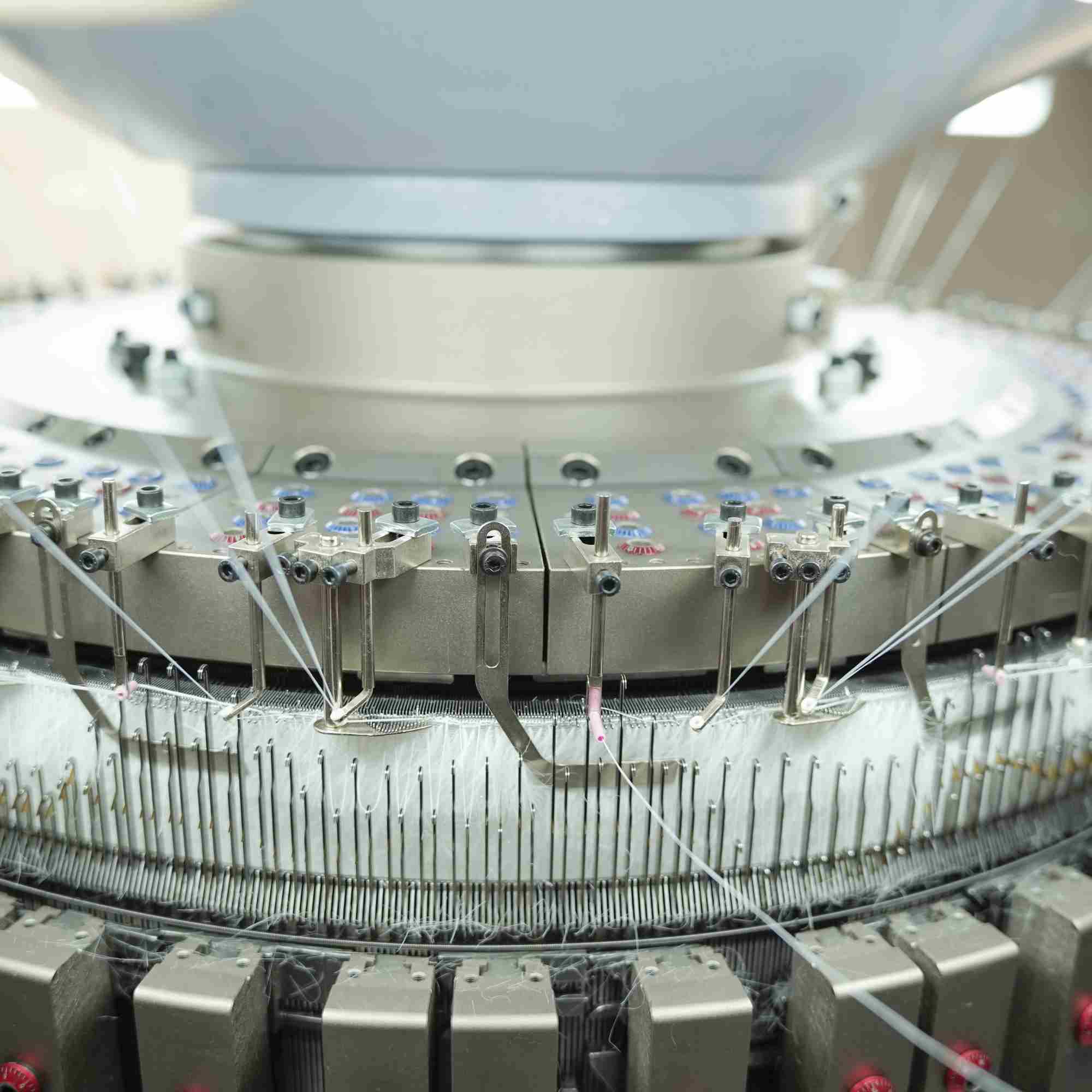

Knitted Fabric Raising and Intermediate Shearing Circular Knitting Machine

This is a specialized circular knitting machine designed for:

Raising (brushing) the surface of knitted fabric to make it soft, fuzzy, or velvet-like.

Intermediate shearing, which refers to the controlled cutting or trimming of fibers raised from the fabric surface to ensure a smooth and even finish.

It usually works with pile fabrics, such as terry, fleece, or brushed knits.

These are typically the main knitting or brushing elements.

In the raising process, upper needles may be part of the brushing rollers or raising drums.

If referring to knitting elements, this can be a high gauge, indicating finer yarns or denser loops.

These may serve as supporting knitting or trimming elements.

In brushing or shearing machines, lower needles could also guide the fabric or provide tension.

⚠️ Note: If this is a circular knitting machine with integrated raising/shearing, then:

26 vs. 13 might refer to the ratio or distribution of needles per inch (gauge) or per segment on upper and lower beds.

Some machines have dual needle beds or combination needle and blade drums.

To fully understand this machine’s spec, you would typically need to know:

Cylinder diameter (e.g., 26", 30")

Gauge (e.g., 18G, 24G — number of needles per inch)

Speed (RPM, revolutions per minute)

Number of feeders

Type of fabric output (e.g., single jersey fleece, interlock brushed)

Machines with this kind of configuration are used in:

Fleece-lined fabric production

Velour or velvet finishing

Activewear and thermal clothing fabric manufacturing

Main Function:

The machine works by passing fabric over rotating rollers equipped with wire-covered surfaces or abrasive materials. These rollers gently pull the surface fibers outward, forming a pile on the fabric. The height and density of the pile can be controlled depending on the settings and configuration of the machine.

Medium Wool 60

Designed for medium-length wool fibers

Uses 60 raising rollers for consistent and balanced fiber lifting

Ideal for medium-weight woolen fabrics needing a soft, uniform finish

Medium Wool Machine

Optimized for processing medium-grade wool

Provides adjustable speed and pressure settings for different fabric densities

Ensures versatility for a range of wool textile applications

High Wool 60

Suited for high-pile wool fabrics requiring deeper raising

Equipped with 60 high-performance rollers

Produces a thicker, warmer texture—ideal for winter apparel and heavy woolen goods

Short Wool 30

Tailored for shorter wool fibers and lighter fabrics

Utilizes 30 raising rollers for a gentler raising effect

Delivers a smooth, soft finish without damaging delicate materials

With rising demand for rib double jersey fabrics in fashion and apparel, the client sought to upgrade their production capabilities and resolve recurring issues with their existing equipment....

The client is a well-established textile producer specializing in high-quality terry fabrics used across various industries. With demand steadily increasing, they recognized the importance of modernizing thei...

The Knitted Fabric Raising and Intermediate Shearing Circular Knitting Machine offers excellent fabric finishing, smooth raising, and precise shearing. It enhances fabric quality and texture, making it ideal for producing soft, high-quality knitted textiles efficiently.2025-07-11

The Circular Knitting Machine provides excellent performance with smooth and stable operation. It ensures consistent fabric quality, high production efficiency, and durable construction. Easy to operate and maintain,2025-07-16