The client is a well-established textile producer specializing in high-quality terry fabrics used across various industries. With demand steadily increasing, they recognized the importance of modernizing their machinery to:

Produce intricate jacquard designs

Enhance production speed and fabric quality

Minimize defects and operational inefficiencies

Seeking a competitive edge, they approached our team with a clear vision and specific technical requirements.

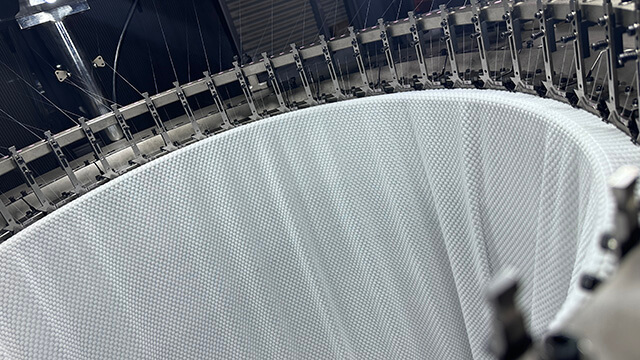

We proposed the Computerized Terry Jacquard Circular Knitting Machine, a cutting-edge solution engineered for high-performance terry fabric production with advanced design capabilities. Key features of the machine include:

Computerized jacquard control system for complex pattern creation

High-speed operation with stable output

Efficient yarn handling to minimize waste and reduce material tension

Superior precision and consistency in stitch formation

These capabilities directly addressed the client's requirements and offered long-term operational benefits.

From consultation to commissioning, our team worked closely with the client to ensure a seamless integration. Our approach included:

Pre-installation assessments to align the setup with existing production lines

On-site installation and configuration by experienced engineers

Hands-on training sessions for machine operators and maintenance staff

Ongoing technical support and troubleshooting

This ensured the client could hit the ground running with their upgraded production setup.

The adoption of the Computerized Terry Jacquard Circular Knitting Machine brought measurable improvements across several key areas:

Expanded Design Capabilities

The machine enabled the production of intricate and customized jacquard patterns, allowing the client to diversify their product offerings and appeal to more demanding markets.

Higher Productivity

Increased speed and automation translated to greater output with fewer delays, helping the client fulfill larger orders and shorten lead times.

Improved Fabric Quality

Thanks to enhanced control and precision, fabric defects were significantly reduced, improving customer satisfaction and lowering rejection rates.

Cost Optimization

The machine’s efficient yarn usage and reduced operational overhead led to notable cost savings, positively impacting the client’s profit margins.

The successful implementation of our Computerized Terry Jacquard Circular Knitting Machine has elevated the client’s manufacturing capabilities and positioned them as a forward-thinking leader in the Russian textile market. They now offer a wider range of superior-quality terry fabrics with increased efficiency and lower operational costs.

This case highlights the transformative impact of adopting innovative knitting technology in a competitive industry. We are proud to have played a role in the client’s growth and look forward to supporting their continued success.