![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

Model:

![]() NET Weight:

NET Weight:

![]() Diameter:

3’’-26’’

Diameter:

3’’-26’’

![]() Gauge:

3G-50G

Gauge:

3G-50G

![]() Feeder:

9F-78F

Feeder:

9F-78F

![]() Certification:

Certification:

![]() Applicable Yarn Material:

Applicable Yarn Material:

![]() RPM:

RPM:

![]() Wooden Box Size:

1.5M*1.5M*2.25M

Wooden Box Size:

1.5M*1.5M*2.25M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

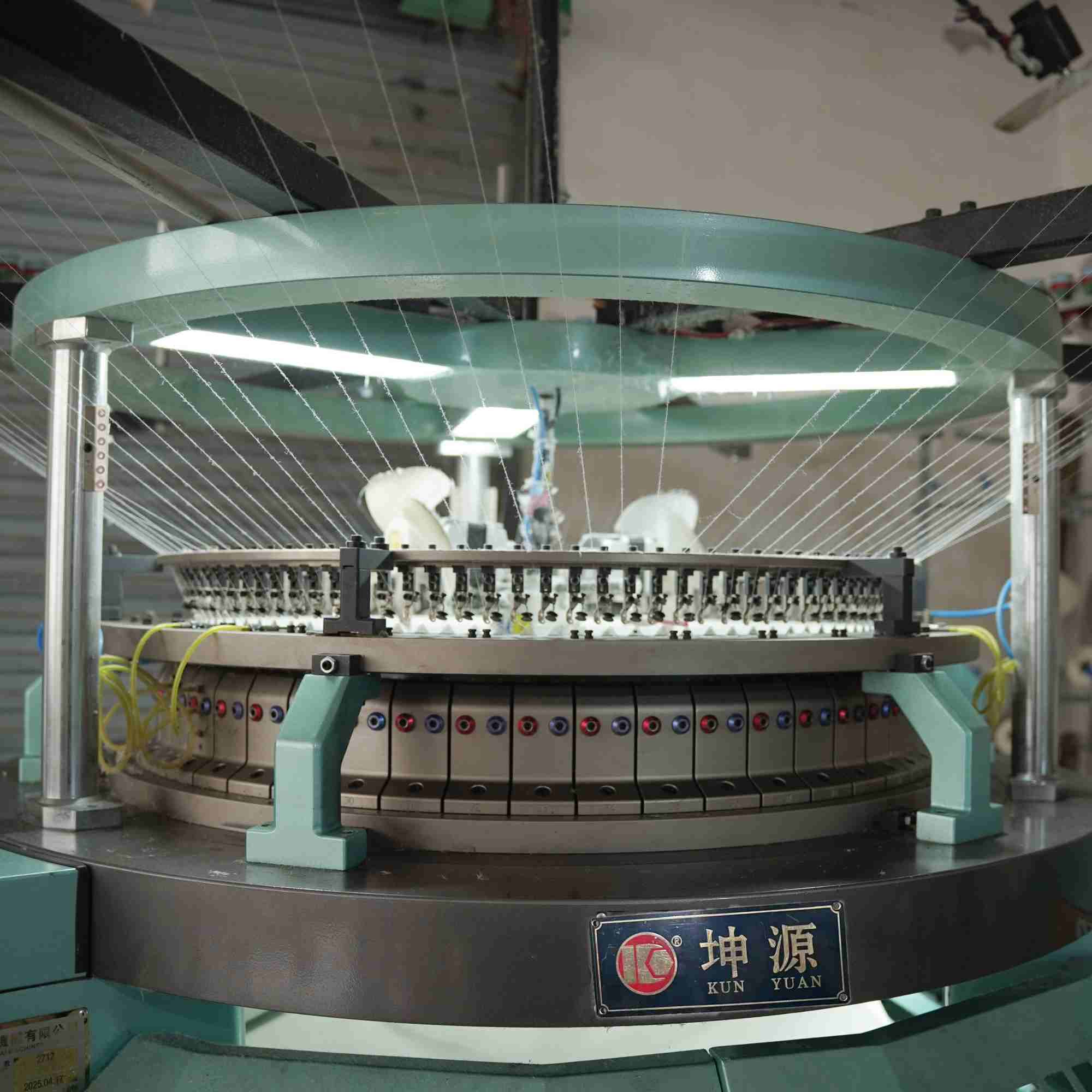

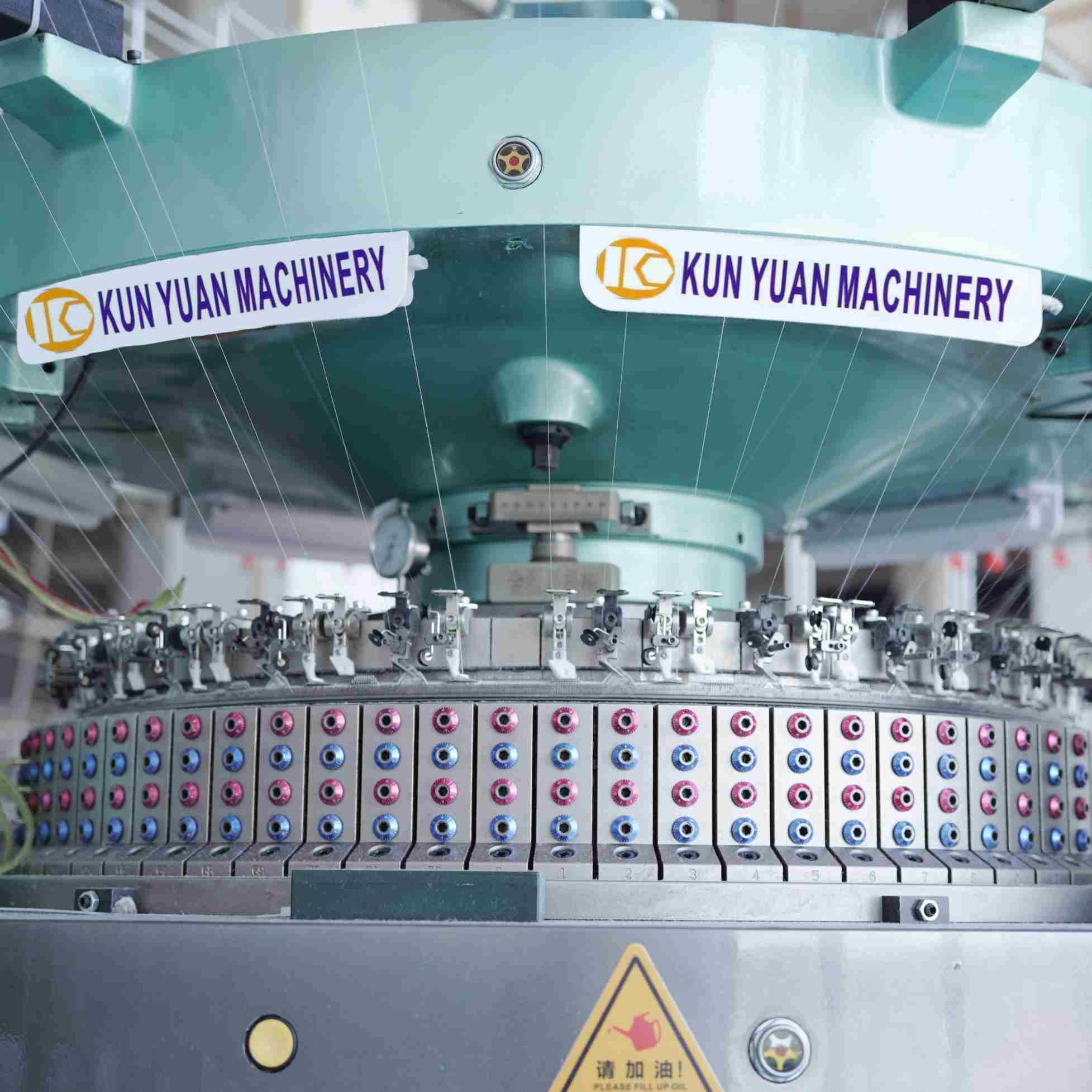

Body Size Circular Knitting Machine is a high-performance, compact knitting solution engineered to produce seamless, body-sized garments efficiently and with precision. Designed to meet the growing demand for streamlined garment manufacturing, this machine is ideal for producing T-shirts, underwear, leggings, nightwear, sweaters, dresses, and more—all without the need for side seams.

Whether you require single jersey or double jersey constructions, this machine offers customizable options to fit a wide range of garment styles and fabric specifications.

Seamless Knitting Capability

Produces full-body-sized tubular garments without the need for additional cutting or stitching, reducing post-production steps.

Compact & High-Speed Design

Engineered for space efficiency and high productivity, the machine is ideal for both small-scale workshops and large manufacturing operations.

Versatile Application Range

Perfect for seamless T-shirts, underwear, leggings, nightwear, and dresses, offering superior comfort and aesthetic appeal.

Gauge Flexibility

Supports a wide gauge range from 3G to 50G, enabling fine to coarse fabric options suitable for various end uses.

Custom Feeder Configurations

Tailored for specific applications with up to 78 feeders, ensuring optimal yarn feeding and pattern control.

| Model | Diameter | Gauge | Feeder Range | Description |

|---|---|---|---|---|

| SBD | 3’’–26’’ | 3G–50G | 9F–78F | Single Jersey Body Size |

| DBD | — | — | 6F–54F | Double Jersey Body Size |

Note: Feeder count varies depending on machine diameter and fabric design.

Seamless Apparel: T-shirts, base layers, underwear

Fashionwear: Bodycon dresses, skirts

Athleisure & Activewear: Leggings, compression garments

Loungewear: Pajamas, sleepwear, nightgowns

Capable of producing any tubular or body-sized seamless knitwear

Designed to meet market demand for mini-size, high-speed production

Compatible with various yarn types for different fabric textures and applications

Routine Maintenance:

Regular cleaning and lubrication are vital to ensure long-term operational efficiency.

Operator Training:

Staff should be adequately trained to handle machine setup, programming, and troubleshooting.

Safety Compliance:

Operators must wear protective clothing and avoid accessories or loose items that can be caught in moving parts.

| Model | Diameter | N.W. Approx | G.W. Approx | Wooden Box Size |

|---|---|---|---|---|

| kunyuan | 20’’ | 1.0T | 1.2T | 1.5m × 1.5m × 2.25m |

Technical Features:

1. Body-size knitting capability: The machine is capable of knitting garments and fabrics in body-size dimensions, ensuring a perfect fit for the wearer.

2. High-speed operation: With its advanced technology, the machine operates at high speeds, increasing productivity and reducing production time.5. Automatic thread tension control: The machine is equipped with automatic thread tension control, ensuring consistent and even knitting throughout the fabric.

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machine combines advanced tec...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate and h...

The Single Jersey Circular Knitting Machine is a highly efficient and versatile textile machinery designed for seamless fabric production. It utilizes a circular knitting technique to create single jersey fab...

The Body Size Circular Knitting Machine is a revolutionary innovation in the textile industry. With its advanced features and capabilities, this machine has found wide-ranging applications in various sectors....

Introduction to High Pile Jacquard Circular Knitting MachineHigh Pile Jacquard Circular Knitting Machine is a specialized machinery used for creating high pile fabrics with intricate designs. It combines the ...

The Body Size Circular Knitting Machine is user-friendly and reliable, delivering consistent fabric quality.2025-07-11