![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

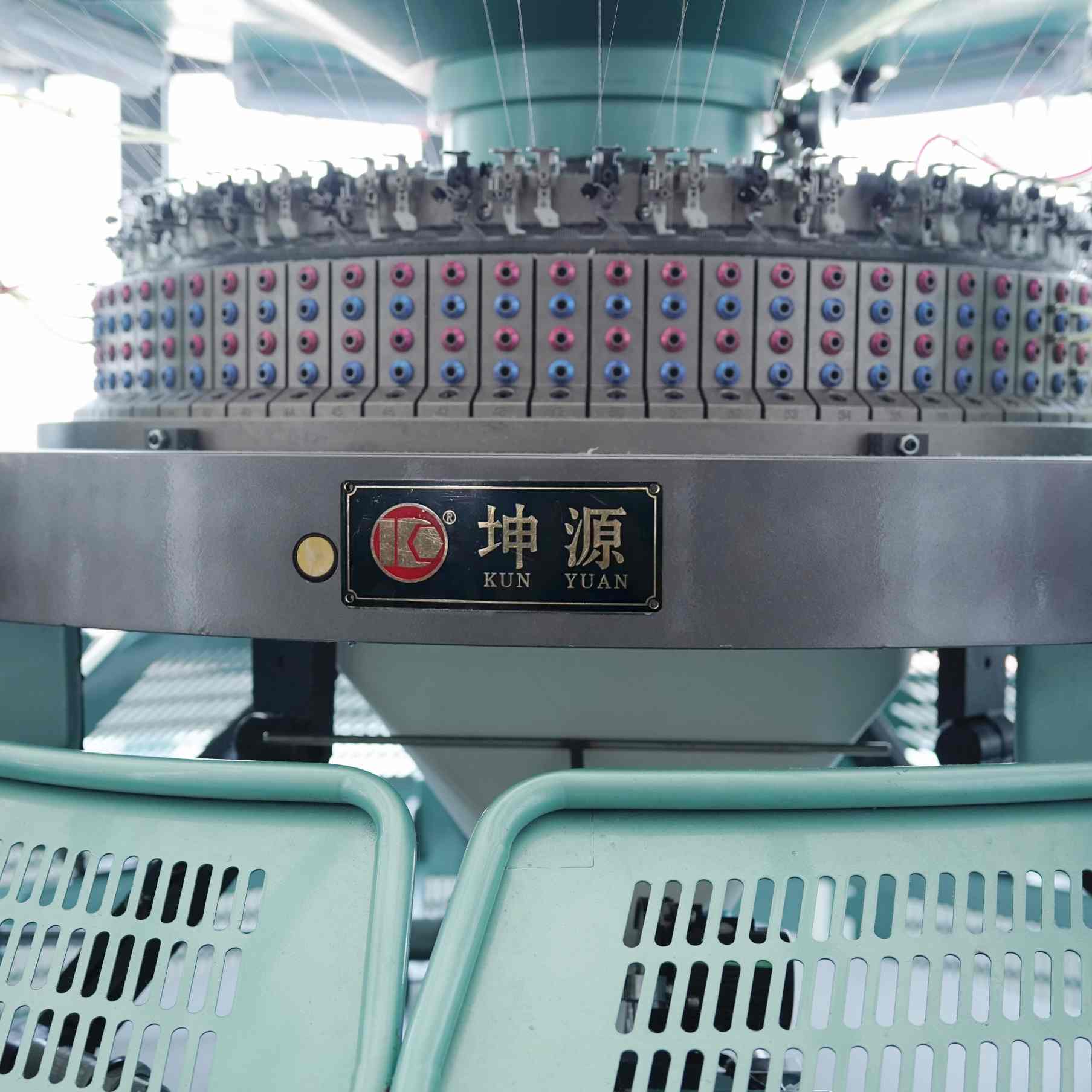

kunyuan

Model:

kunyuan

![]() NET Weight:

4 tons

NET Weight:

4 tons

![]() Diameter:

30

Diameter:

30

![]() Gauge:

8G-36G

Gauge:

8G-36G

![]() Feeder:

64F

Feeder:

64F

![]() Certification:

CE, ISO

Certification:

CE, ISO

![]() Applicable Yarn Material:

Fashion cloth, Curtain, Sofa fabric, Mattress

Applicable Yarn Material:

Fashion cloth, Curtain, Sofa fabric, Mattress

![]() RPM:

12-18PRM

RPM:

12-18PRM

![]() Wooden Box Size:

2.7M*2.3M*2.5M

Wooden Box Size:

2.7M*2.3M*2.5M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

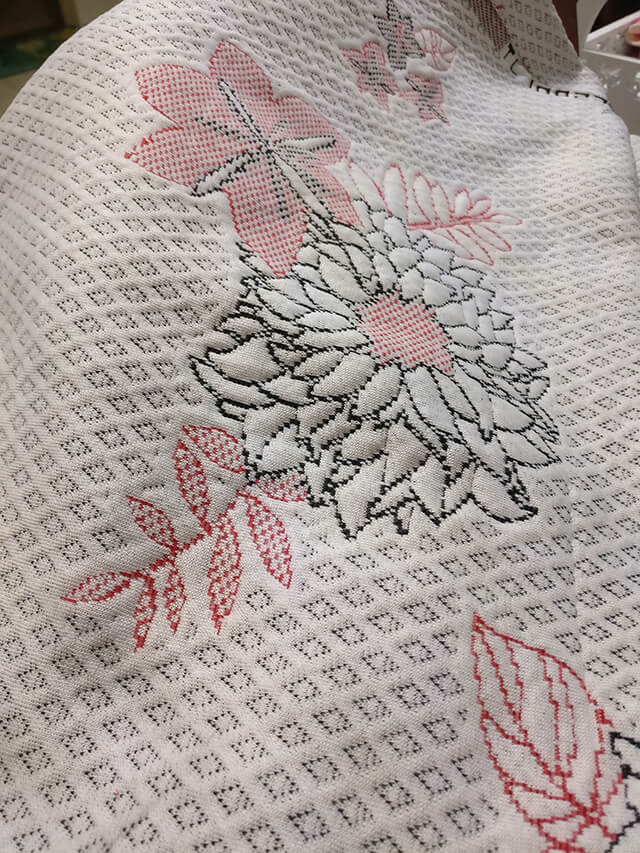

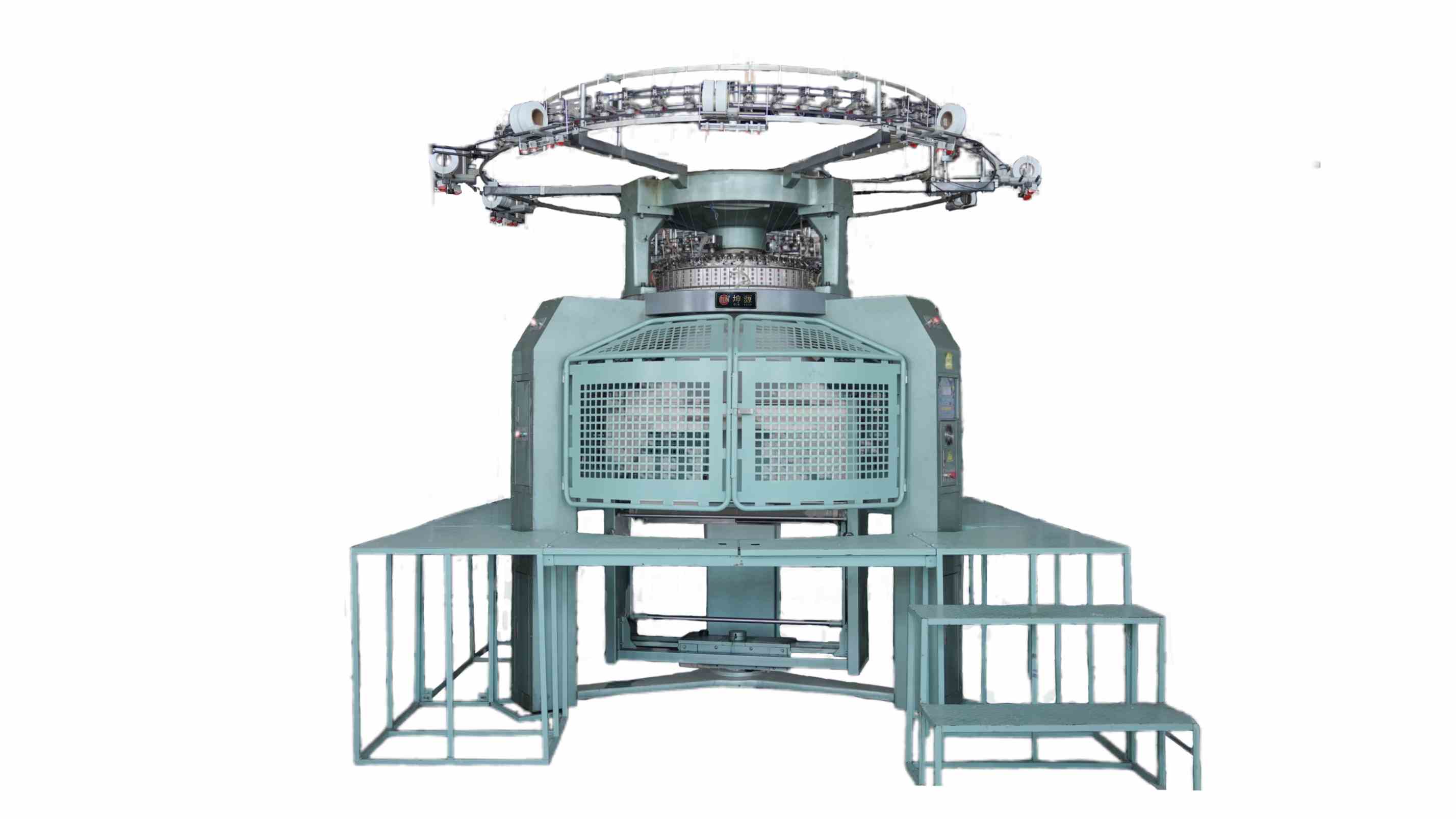

The Double Jacquard Circular Knitting Machine is a high-performance, computerized textile solution designed for producing intricate and multicolored jacquard patterns in circular knitted fabrics. Engineered for both precision and productivity, this machine is ideal for manufacturers seeking to create premium fabrics with rich design complexity for applications such as fashion apparel, home textiles, and upholstery.

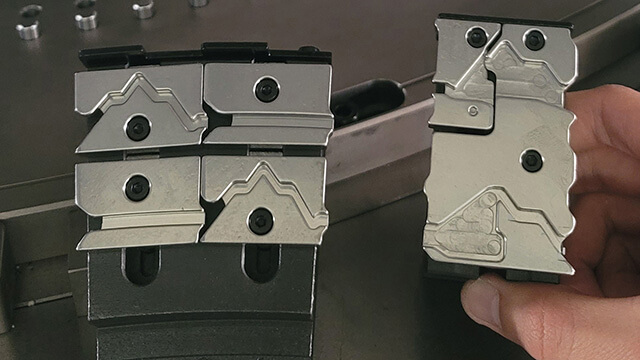

Double Jacquard Capability

Equipped with a dual jacquard system that enables the production of complex, multicolored patterns, including logos, images, and geometric designs. It offers unmatched design flexibility for high-end textile applications.

High Speed and Efficiency

Built for high-speed operation, the machine ensures superior output without compromising fabric quality. Advanced tension control delivers uniform stitch formation and excellent elasticity, reducing fabric defects.

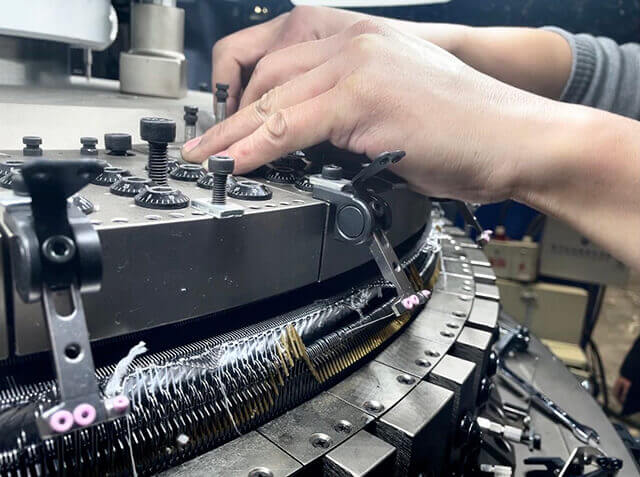

Fully Computerized Needle Selection

Integrated with an electronic needle selector that supports knit, tuck, and miss functions, allowing a wide variety of knitting styles with precise control.

Multilingual User Interface

Features a user-friendly computer panel available in multiple languages. Operators can quickly program designs, adjust parameters, and monitor production in real time.

Ideal for a broad range of fabric applications, including:

Fashion garments

Underwear

Sportswear

Mattresses

Curtains

Sofa upholstery

Yarn Selection: Use yarns that are suitable in thickness and quality for the intended pattern. Mismatched yarn may cause pattern distortion or breakage.

Routine Maintenance: Regular lubrication, needle inspection, and general cleaning are essential for ensuring peak performance and extending machine life.

Operator Training: Ensure machine is handled by trained technicians familiar with electronic jacquard programming and troubleshooting.

Computerized jacquard circular knitting system

Fully electronic needle selector (supports knit, tuck, and miss)

Multilingual computer system for global usability

High-resolution pattern reproduction

| Diameter | Gauge | Feeder | Recommended RPM |

|---|---|---|---|

| 30” | 7G–36G | 64F | 12–18 RPM |

| 34” | - | 72F | 12–18 RPM |

| 38” | - | 96F | 12–18 RPM |

Note: Actual machine speed should be selected based on yarn quality, knitting conditions, and gauge.

| Model | Diameter | Net Weight | Gross Weight | Packing Dimensions |

|---|---|---|---|---|

| kunyuan | 38” | Approx. 3.5T | Approx. 4.0T | 2.7M × 2.3M × 2.5M (Wooden Box) |

Double Needles: The machine uses two sets of needles, one for the front and one for the back. This allows for different patterns or colors to be knitted on each side of the fabric, which can create reversible fabrics or more intricate designs.

Circular Knitting: It’s a circular machine, meaning it creates tubular fabric. The fabric is knitted in a continuous tube and then cut to create flat pieces (such as sweater panels, shirts, etc.).

Jacquard Patterning: The Jacquard technique allows for patterns to be controlled automatically. This is usually done by a punch card system or more modern digital control systems. The machine can create complex, multi-color designs with intricate shapes or textures that would be difficult or impossible to achieve with simpler knitting machines.

High Efficiency: These machines are highly efficient, capable of knitting a variety of complex designs at high speeds, which is ideal for mass production of patterned fabrics.

Knitwear: Double jacquard machines are often used for high-quality knitwear, including sweaters, cardigans, and other apparel items that require detailed patterns.

Sportswear: This machine is also used in producing sportswear or activewear fabrics, as it can create designs that are both aesthetically pleasing and functional.

Home Textiles: Bedding, upholstery fabrics, and other home textiles may also be produced using this type of machine, especially when a reversible or complex pattern is desired.

Main Functions:

1.Jacquard Pattern Creation: The machine allows for the creation of jacquard patterns by selectively controlling individual needles. This enables the production of intricate designs and patterns with multiple colors.

2.Variable Fabric Structures: The machine offers versatility in fabric structures by allowing adjustments in stitch types and densities. This capability provides flexibility to create different textures and appearances in the finished fabrics.

3. Continuous Production: The machine can operate continuously, enabling efficient production with minimal downtime. It is designed to handle large volumes of fabric production while maintaining consistent quality.In conclusion, the Double Jacquard Circular Knitting Machine is a technologically advanced and versatile solution for textile manufacturers seeking to produce intricate and high-quality fabrics. With its double jacquard capability, high speed, and user-friendly interface, it offers excellent functionality for a wide range of applications in the fashion, home textile, and related industries.

Application Areas:The Double Jacquard Circular Knitting Machine finds applications in various industries, including:

1. Fashion and Apparel:

The machine is widely used in the production of high-end knitwear, such as sweaters, dresses, and accessories. Its ability to create complex patterns adds value and uniqueness to the finished products.

2. Home Textiles:

The machine is suitable for producing intricate and decorative fabrics used in home textiles, including curtains, upholstery, and beddings.

This machine is engineered for precision knitting of high-density threaded fabrics, particularly for garment components such as collars, cuffs, and waistbands. The 60-gauge configuration provides an ultra-...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

The 36-inch, 32-gauge, 108 feeders ordinary double jersey circular knitting machine is widely used in the production of fine, high-density double-knit fabrics. It is suitable for various applications acros...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to interchange threads ...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control systems and double-...

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15