![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

34‘’18G60F

Model:

34‘’18G60F

![]() NET Weight:

2.5tons

NET Weight:

2.5tons

![]() Diameter:

1.9m

Diameter:

1.9m

![]() Gauge:

18

Gauge:

18

![]() Feeder:

60

Feeder:

60

![]() Certification:

ISO,CE

Certification:

ISO,CE

![]() Applicable Yarn Material:

SUN

Applicable Yarn Material:

SUN

![]() RPM:

20

RPM:

20

![]() Wooden Box Size:

H4m

Wooden Box Size:

H4m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

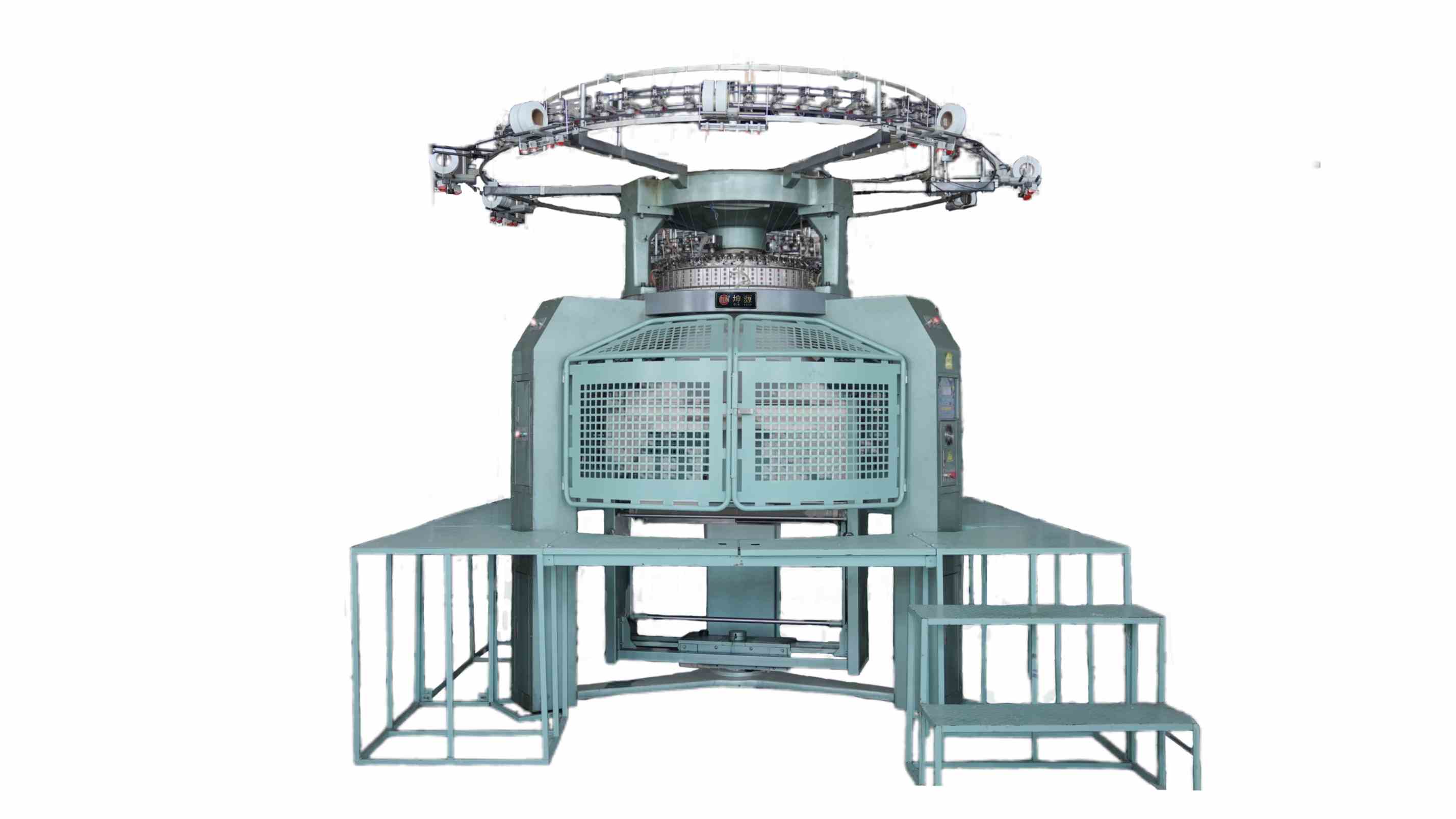

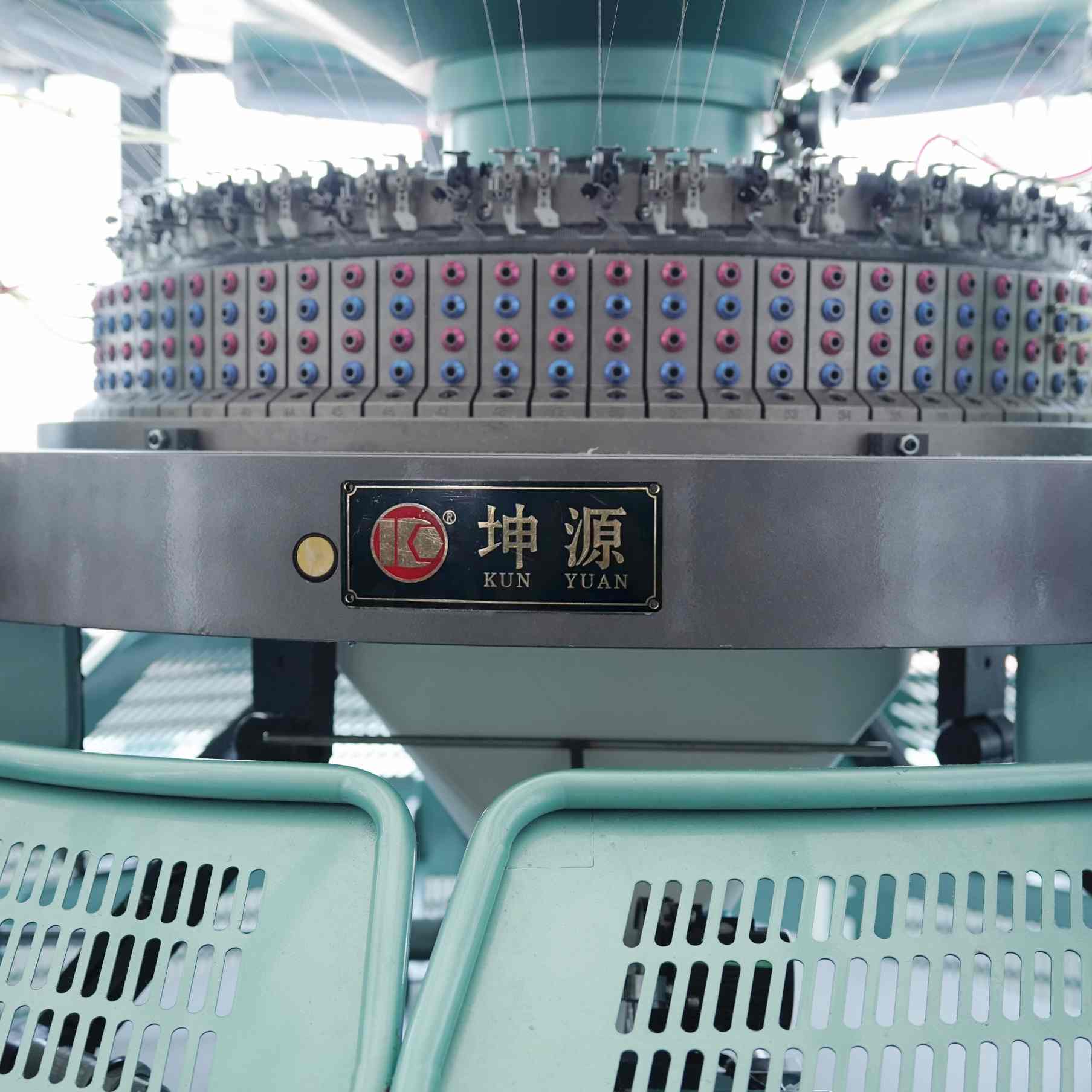

Pneumatic High Foot Thread Knitting Machine – Technical Specifications

Model: 34'' 60G 18F

Diameter: 1.9 meters

Gauge: 60G (60 needles per inch)

Number of Feeders: 18 feeders

Weight: 2.5 tons

Speed: 20 revolutions per minute (RPM)

This machine is engineered for precision knitting of high-density threaded fabrics, particularly for garment components such as collars, cuffs, and waistbands. The 60-gauge configuration provides an ultra-fine knitting structure, making it ideal for detailed, elastic trim production. With a 1.9-meter diameter and 18 yarn feeders, it offers stable and efficient output, while the pneumatic high foot design allows it to handle thicker or specialty yarns with ease. The 2.5-ton weight ensures stable operation, and the 20 RPM speed offers a balance between productivity and quality.

1. Machine Type:

Pneumatic High Foot Thread Circular Knitting Machine

2. Diameter of the Machine:

Usually ranges from 30 inches to 48 inches (can vary by machine)

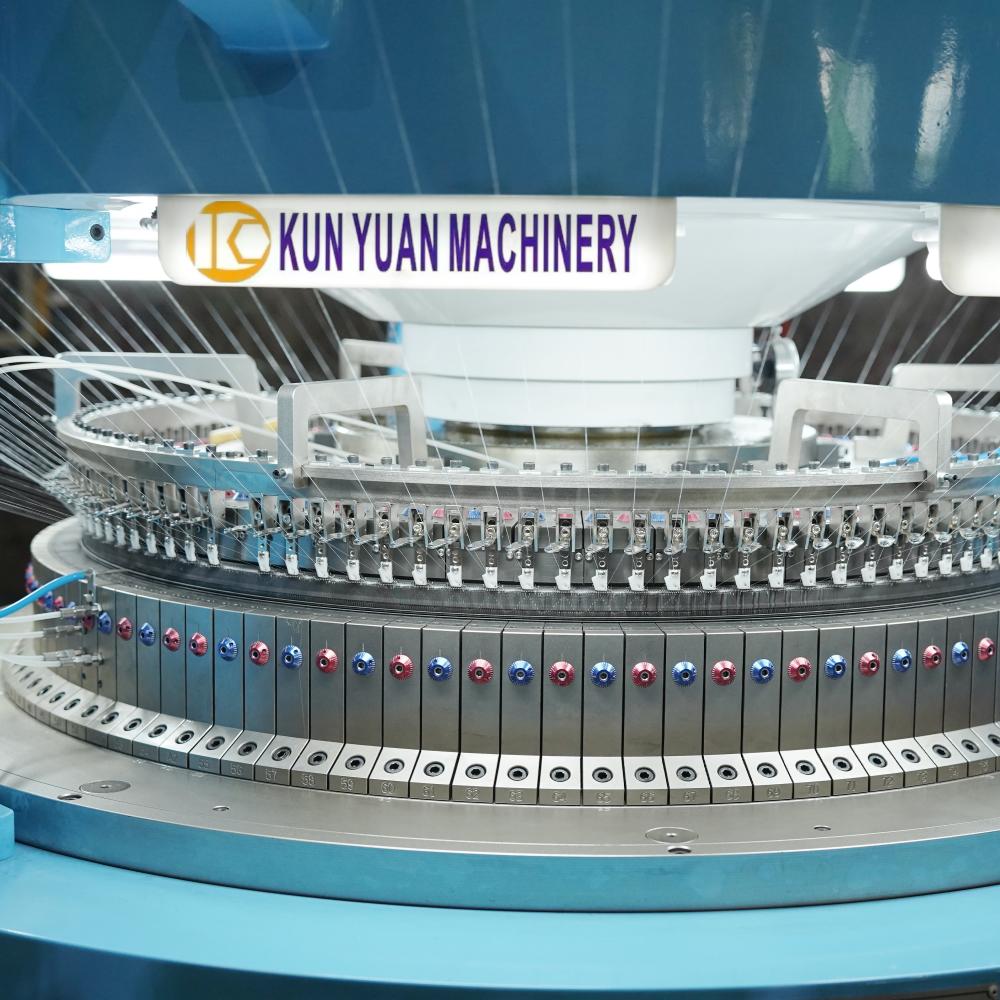

3. Number of Needles:

Varies typically between 480 to 1500 needles depending on diameter and gauge

4. Gauge (Needle Density):

Common gauges are 10, 12, 14, 16, 18, or higher (fine gauge for finer fabric)

5. Speed:

Operating speed usually ranges from 15 to 30 RPM (can be higher depending on model)

6. Stitch Length:

Adjustable, typically between 2.5 mm to 5.0 mm

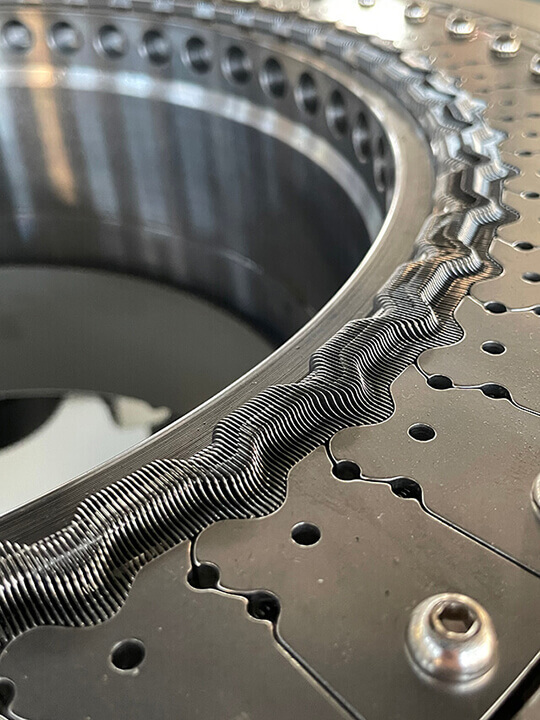

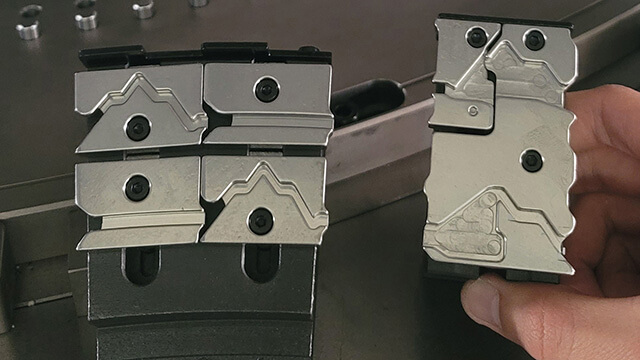

7. Needle Type:

Standard latch needles or bearded needles (depends on model and fabric type)

8. Pneumatic System:

Uses compressed air to control high foot mechanism, allowing precise control over stitch formation and fabric tension

Air pressure typically adjustable around 4-6 bar (60-90 psi)

9. Drive System:

Motor-driven with variable speed control

Usually equipped with inverter or servo motor for speed regulation

10. Frame Material:

Heavy-duty cast iron or steel for stability and vibration resistance

11. Yarn Feeding:

High foot thread feeding system, suitable for a variety of yarn types including cotton, wool, synthetic, or blends

12. Fabric Type:

Designed for knitting circular fabric, often for socks, hosiery, seamless garments, and technical textiles

13. Dimensions & Weight:

Machine dimensions typically large, weight can range from 500 kg to over 1000 kg

14. Control System:

Manual or PLC-based control for modern versions

Pneumatic control for foot lift and stitch length adjustment

15. Additional Features:

Quick-change needle cylinder

Pneumatic foot lifter for ease of knitting pattern changes

Automatic lubrication system (on some models)

Safety covers and emergency stop buttons

Pneumatic High Foot Thread Knitting Machine – Function

The Pneumatic High Foot Thread Knitting Machine is a specialized knitting machine designed for the production of special thread cloth with high precision and efficiency. It is equipped with a pneumatic (air-powered) lifting system, which allows for faster, smoother, and more stable operation compared to traditional mechanical systems.

Knitting of Special Thread Cloth

Specifically engineered to handle specialty yarns and threads, including elastic, thick, or textured yarns.

Ensures even tension and consistent quality in complex or heavy fabrics.

High Foot Design for Thick Fabrics

The high foot clearance allows the machine to work with bulky or multi-layered fabrics, which are difficult to process on standard machines.

Ideal for creating structured, raised, or dimensional knit fabrics.

Pneumatic Control System

Uses compressed air to control lifting and pressing movements with precision and speed.

Reduces manual adjustments, improves production efficiency, and minimizes mechanical wear.

Versatile Fabric Creation

Capable of producing ribbed, threaded, or textured fabrics used in specialized garments or functional textiles.

Application of the Pneumatic High Foot Thread Knitting Machine

The Pneumatic High Foot Thread Knitting Machine is widely used in the garment manufacturing industry for the production of threaded components that require elasticity, durability, and a clean finish. Its advanced pneumatic system and high foot design make it particularly suitable for creating detailed, structured knit parts used in various sections of clothing.

Thread Collars (Knitted Collars)

Produces elastic and form-fitting collars for t-shirts, polo shirts, jackets, and sweaters.

Offers excellent shape retention and stretchability for comfort and durability.

Thread Edges (Cuffs and Hems)

Used to knit ribbed or threaded edges for sleeves, bottom hems, and necklines.

Ensures a snug fit and prevents fabric from rolling or fraying.

Thread Waistbands

Ideal for producing waistbands for sportswear, casual pants, skirts, and undergarments.

Provides the necessary flexibility and support for active movement and daily wear.

Consistent quality for mass production

Capable of handling specialty yarns and elastic threads

Smooth, efficient operation with reduced manual effort thanks to pneumatic lifting

The 36-inch, 32-gauge, 108 feeders ordinary double jersey circular knitting machine is widely used in the production of fine, high-density double-knit fabrics. It is suitable for various applications acros...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Provides a wide knitting...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational stability. Ensures e...

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16