![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

36-inch, 32 gauge, 108 feeders

Model:

36-inch, 32 gauge, 108 feeders

![]() NET Weight:

2500-3200kg

NET Weight:

2500-3200kg

![]() Diameter:

36inches≈914mm

Diameter:

36inches≈914mm

![]() Gauge:

32G

Gauge:

32G

![]() Feeder:

108yarn feeders

Feeder:

108yarn feeders

![]() Certification:

CE,ISO

Certification:

CE,ISO

![]() Applicable Yarn Material:

Combed Cotton,Polyester,Modal,Spandex

Applicable Yarn Material:

Combed Cotton,Polyester,Modal,Spandex

![]() RPM:

15-25rpm(mechanical),up to rpm

RPM:

15-25rpm(mechanical),up to rpm

![]() Wooden Box Size:

2m*2m*2.5m

Wooden Box Size:

2m*2m*2.5m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

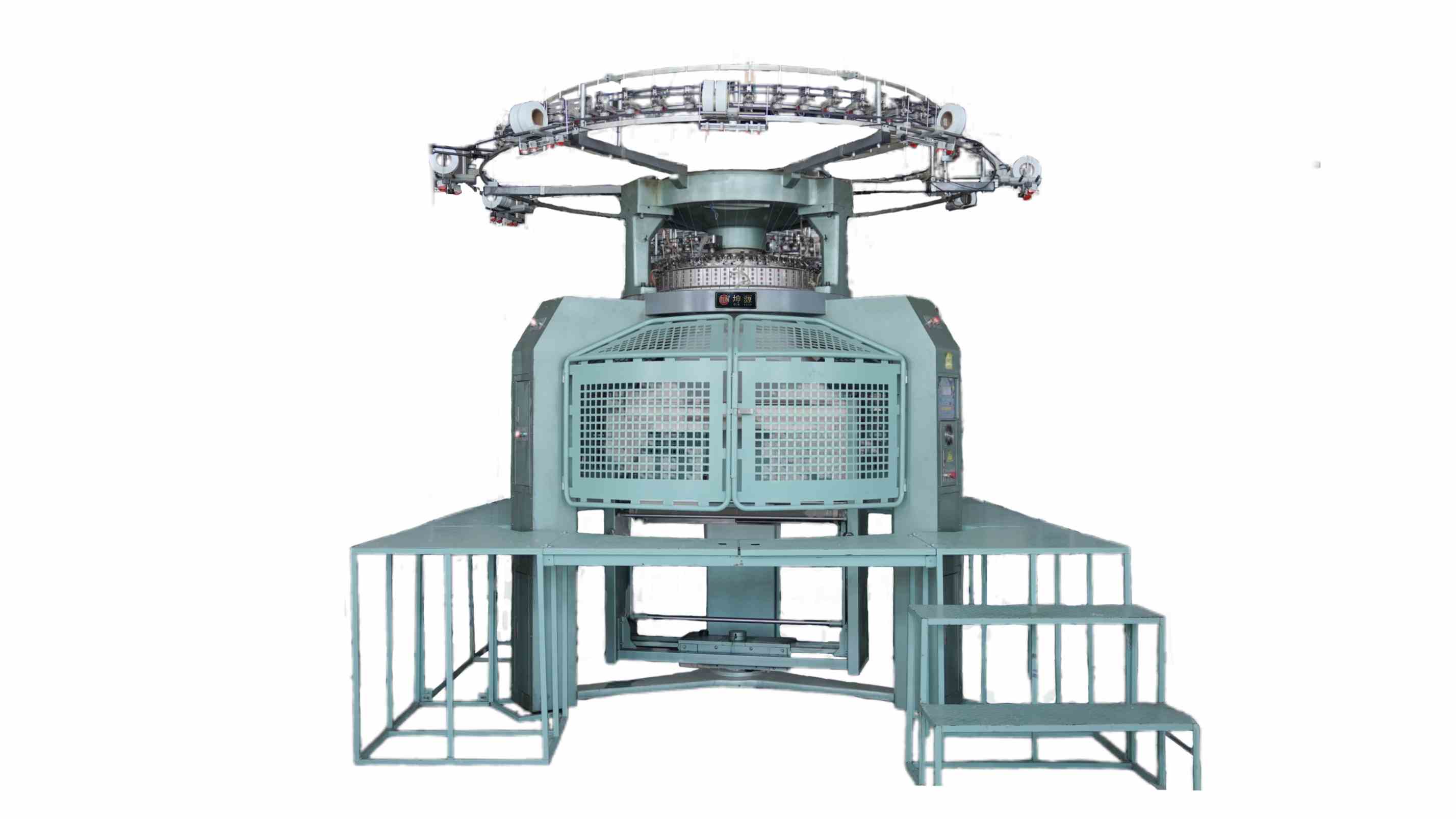

The 36-inch, 32-gauge, 108 feeders ordinary double jersey circular knitting machine is widely used in the production of fine, high-density double-knit fabrics. It is suitable for various applications across the garment, functional textile, home textile, and medical industries.

High-quality T-shirt fabrics

Sportswear fabrics (moisture-wicking, breathable)

Underwear and base layer fabrics

Thermal innerwear

Baby and children's clothing (soft and skin-friendly)

Spandex double jersey for yoga wear, activewear, leggings, etc.

Polyester or nylon-based technical fabrics with cooling or quick-dry properties

Fabrics with special functions: antibacterial, UV protection, far-infrared, moisture management

Knitted bed linens, such as pillowcases and fitted sheets

Elastic sofa covers and decorative knitted fabrics

Base fabrics for composite materials

Medical-grade innerwear fabrics (lightweight, breathable)

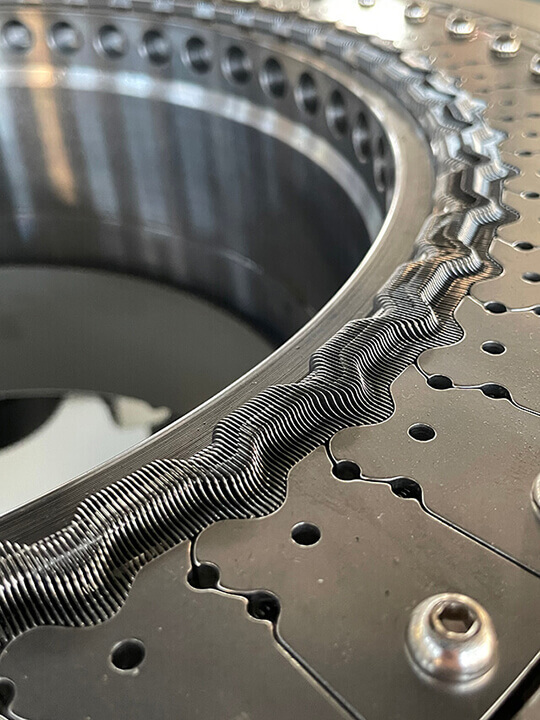

32 gauge: Ideal for producing fine, smooth, and dense fabrics

Double jersey structure: Provides durability and elasticity on both sides

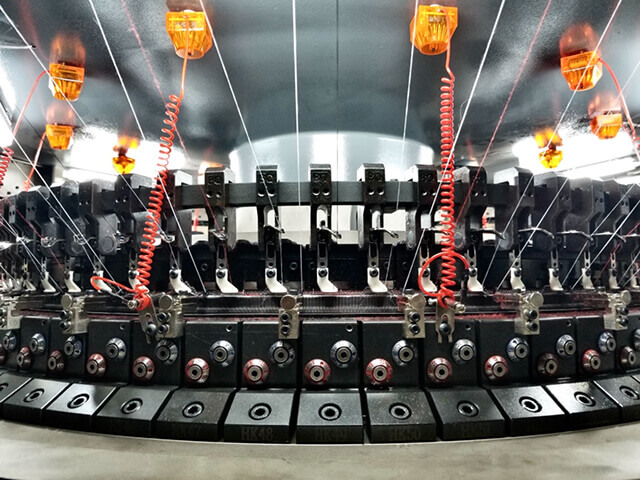

108 feeders: Enables high-efficiency production with multiple yarn types

Compatible with cotton, polyester, modal, bamboo fiber, and spandex blends

| Item | Specification |

|---|---|

| Machine Type | Ordinary Double Jersey Circular Knitting Machine |

| Cylinder Diameter | 36 inches (≈ 914 mm) |

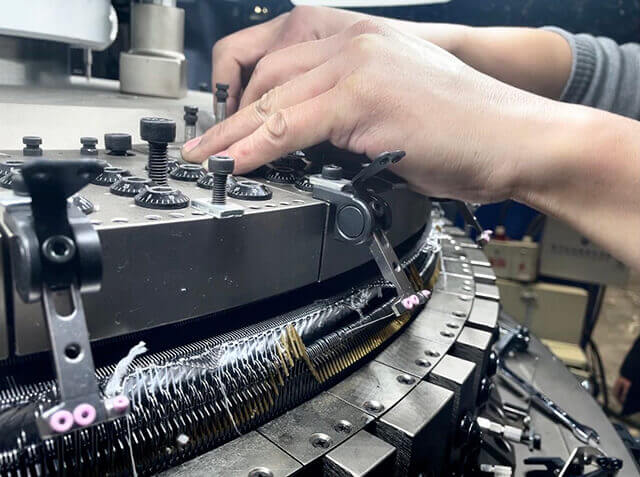

| Gauge (G) | 32G (32 needles per inch) – for fine, dense double-knit fabrics |

| Number of Feeders | 108 feeders (standard for high-speed, high-efficiency production) |

| Needle Count | Approx. 2,880 needles (varies depending on sinker configuration) |

| Fabric Output | Double jersey, interlock, rib, pique, mesh, waffle, etc. |

| Knitting Speed | 15 – 30 RPM (depends on yarn, structure, and fabric type) |

| Drive Motor Power | 5.5 – 7.5 kW (usually with inverter control) |

| Take-up System | Roll-up take-up (optional: pneumatic open-width take-up) |

| Control System | Inverter-controlled motor, digital row counter, stop motion device |

| Lubrication System | Automatic lubricator / centralized oiling system |

| Main Frame | Heavy-duty cast iron frame, vibration-resistant |

| Machine Size | Approx. 227 cm (L) × 197 cm (W) × 227 cm (H) |

| Net Weight | Approx. 2,400 kg |

| Gross Weight | Approx. 2,800 kg (with wooden case for export) |

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitting, it offers high-s...

The 36-inch, 32-gauge, 108 feeders ordinary double jersey circular knitting machine is widely used in the production of fine, high-density double-knit fabrics. It is suitable for various applications acros...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational stability. Ensures e...

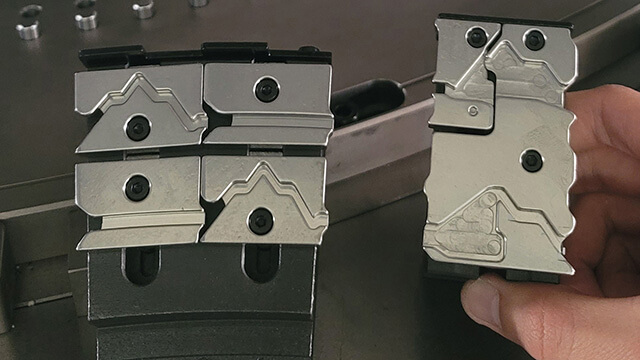

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to interchange threads ...

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11