![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

34''28G72F

Model:

34''28G72F

![]() NET Weight:

4tons

NET Weight:

4tons

![]() Diameter:

1.9m

Diameter:

1.9m

![]() Gauge:

28

Gauge:

28

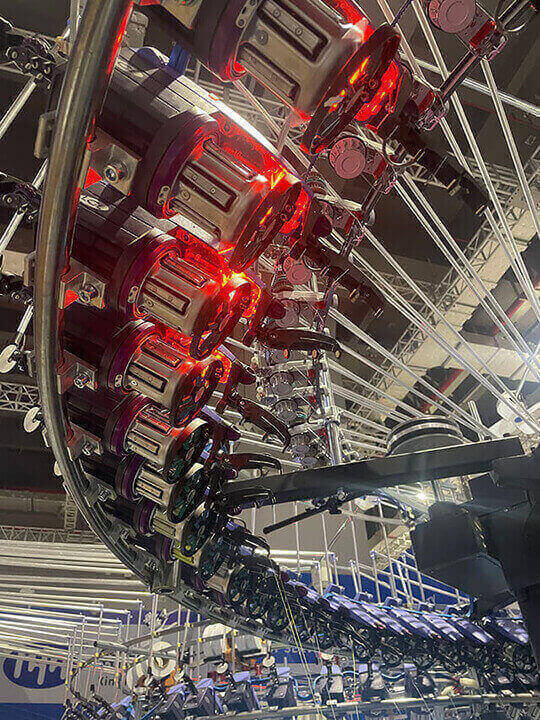

![]() Feeder:

72

Feeder:

72

![]() Certification:

ISO,CE

Certification:

ISO,CE

![]() Applicable Yarn Material:

Sun

Applicable Yarn Material:

Sun

![]() RPM:

18

RPM:

18

![]() Wooden Box Size:

H3m

Wooden Box Size:

H3m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

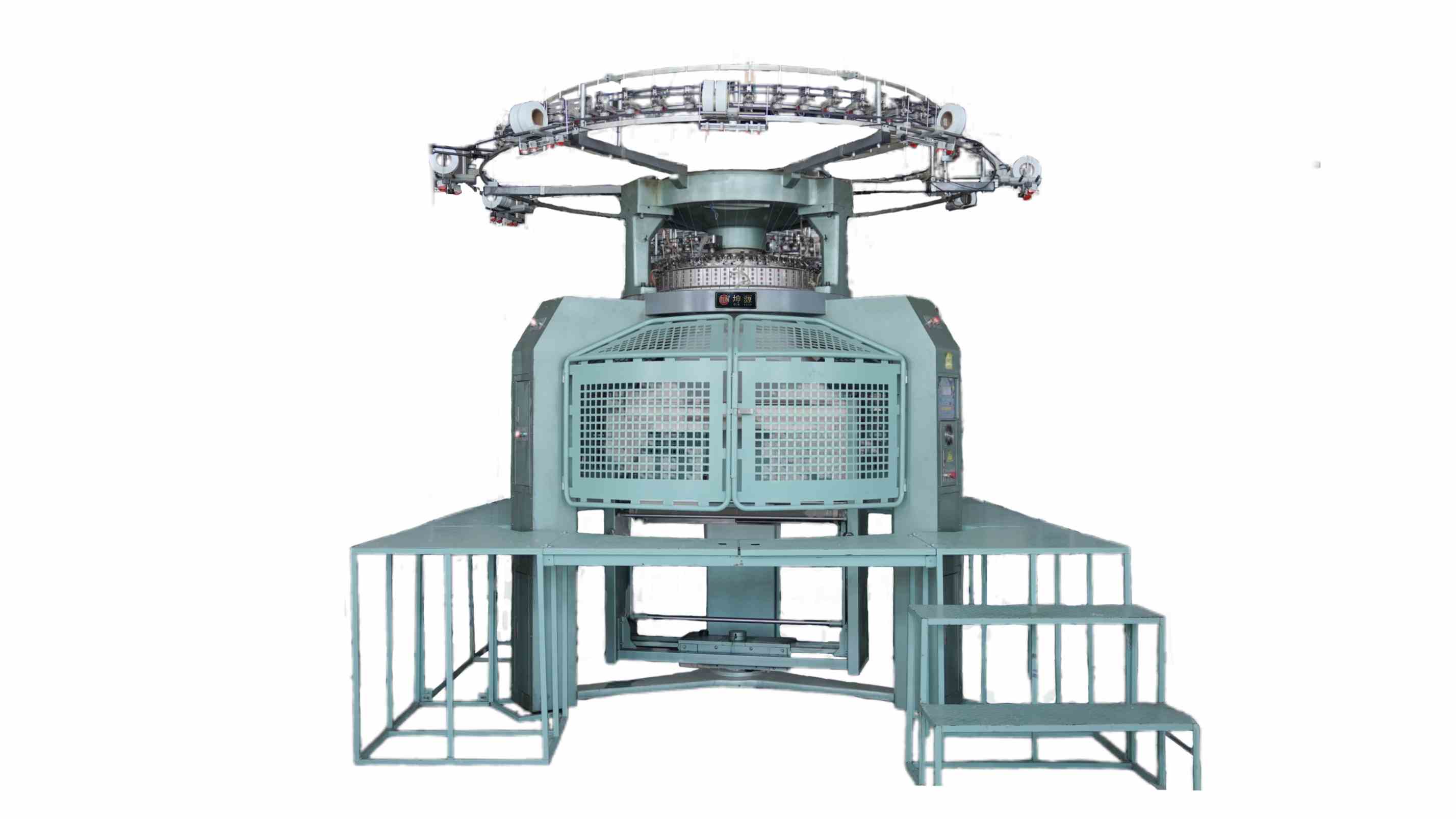

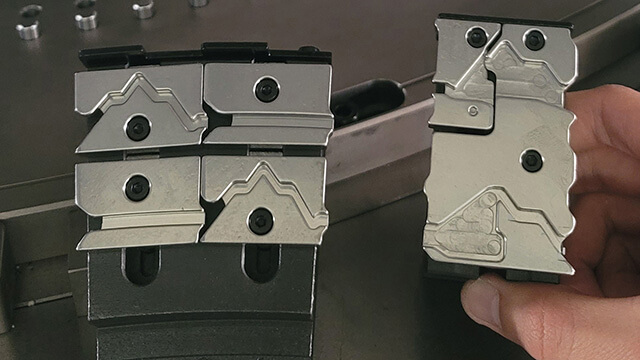

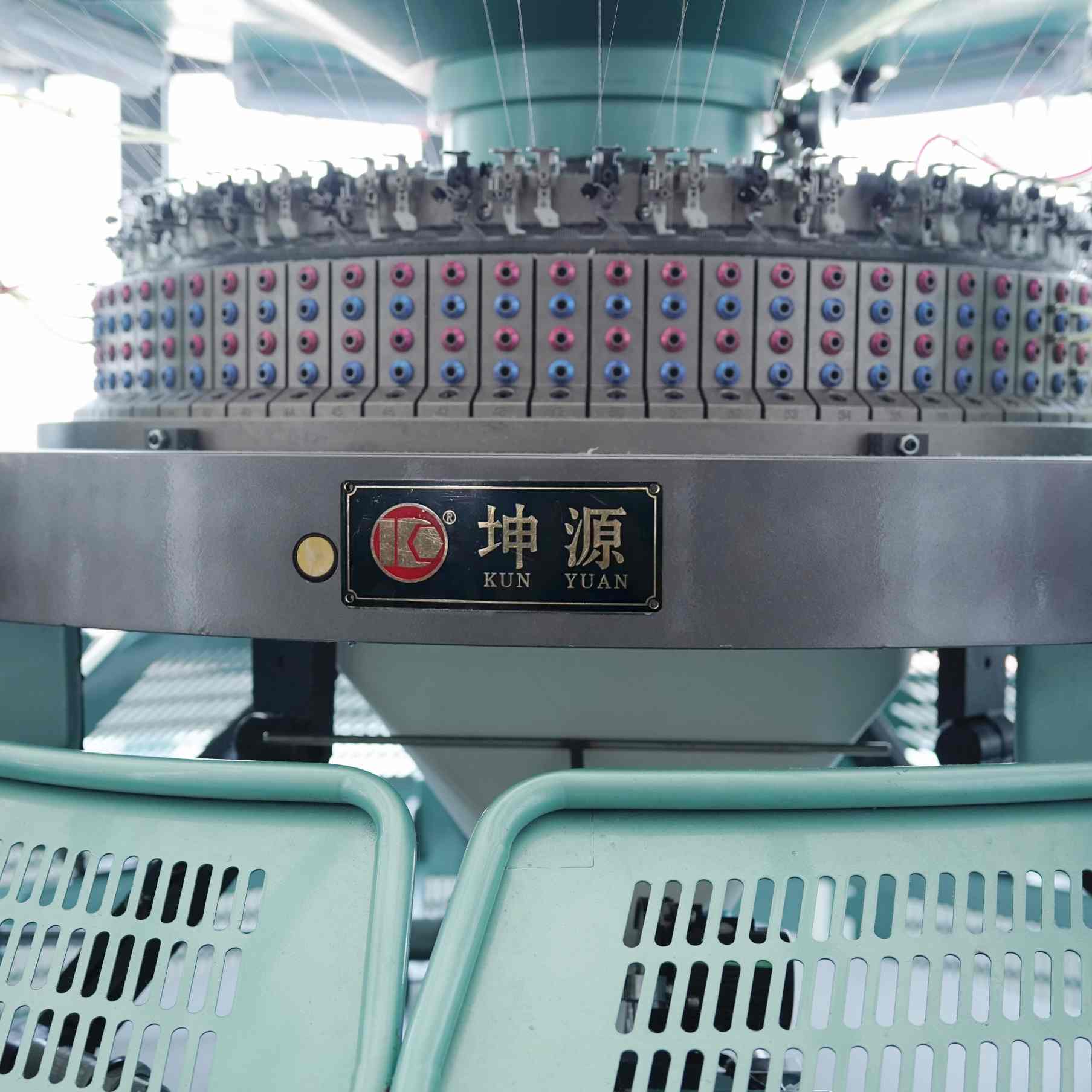

Pneumatic Double-sided High-foot Opening Knitting Machine Technical Specifications

Model: 34'' 28G 72F

Diameter: 1.9 meters

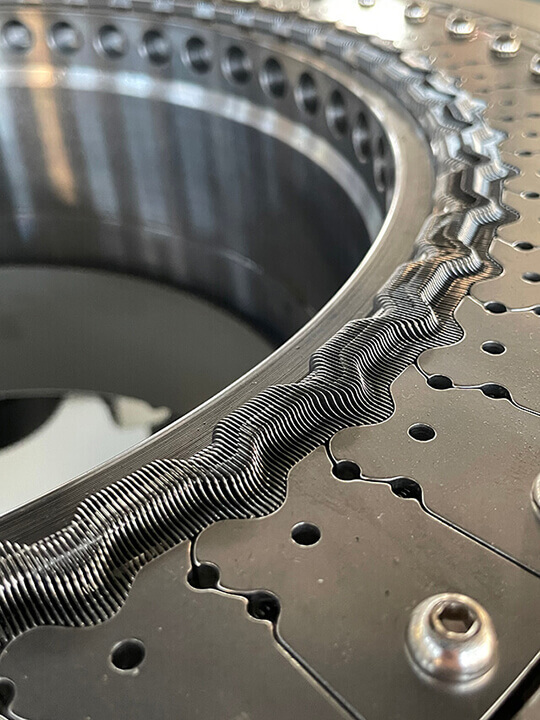

Gauge: 28G (28 needles per inch)

Number of Feeders: 72 feeders

Weight: 24 tons

Speed: 18 revolutions per minute (RPM)

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balances fabric density and breathability, while the 72 feeders ensure smooth and continuous yarn supply for consistent knitting. With a large 1.9-meter diameter and heavy-duty construction weighing 24 tons, it offers exceptional stability during operation. The 18 RPM speed provides a controlled knitting process, ensuring fabric quality and precision. The pneumatic high-foot design allows for knitting thicker fabrics and handling specialty yarns efficiently.

| Specification | Details |

|---|---|

| Model | 34''28G72F |

| Needle Bed Width | 34 inches |

| Gauge | 28G (28 needles per inch) |

| Type | Double-sided (produces two layers) |

| Knitting Type | Circular Knitting (for continuous fabric production) |

| Control System | Pneumatic (precise air-powered control) |

| Fabric Type | Suitable for jersey, rib, interlock fabrics, and more |

| Knitting Speed | High-speed operation |

| Power Source | Pneumatic (compressed air required) |

| Foot Design | High-foot opening (easy maintenance) |

| Control System | Electronic control for automation |

| Production Capacity | High output, ideal for mass production |

| Applications | Garments, sportswear, innerwear, and other knitted textiles |

Pneumatic Double-sided High-foot Opening Knitting Machine – Function

The Pneumatic Double-sided High-foot Opening Knitting Machine is an advanced textile machine designed for producing double-sided knitted fabrics with superior texture and structural integrity. Equipped with a pneumatic lifting system and high foot clearance, it allows for the efficient handling of thicker yarns and complex fabric constructions.

Double-sided Fabric Production

Capable of knitting fabrics with two finished sides, providing enhanced durability, comfort, and aesthetic appeal.

Produces balanced, stable fabrics ideal for demanding applications.

High Foot Design for Thick and Healthy Fabrics

The high foot clearance enables knitting of thicker, multi-layered fabrics without yarn damage.

Perfect for creating healthy fabrics—breathable, skin-friendly, and durable materials often used in school uniforms.

Pneumatic Control for Precision and Efficiency

Uses compressed air technology for smooth, fast, and accurate fabric formation.

Reduces mechanical wear and enhances machine responsiveness.

Versatile Fabric Creation

Suitable for manufacturing school uniform fabrics that require durability, colorfastness, and comfort.

Supports production of fabrics with anti-pilling, moisture-wicking, and easy-care properties.

Summary:

The Pneumatic Double-sided High-foot Opening Knitting Machine is ideal for manufacturers specializing in school uniform textiles and healthy, functional fabrics, combining advanced pneumatic technology with robust design to deliver high-quality, double-sided knit fabrics with excellent performance and comfort.

Application of the Pneumatic Double-sided High-foot Opening Knitting Machine

The Pneumatic Double-sided High-foot Opening Knitting Machine is primarily used in the production of school uniform fabrics, where durability, comfort, and appearance are essential. Its advanced design and pneumatic control system enable the manufacture of high-quality double-sided knitted fabrics that meet the rigorous demands of schoolwear.

School Uniform Fabrics:

Produces strong, durable, and comfortable fabrics suitable for daily wear by students.

Ensures fabrics are breathable, easy to maintain, and resistant to wear and tear.

Functional Textiles for Schoolwear:

Supports the creation of fabrics with anti-pilling, moisture-wicking, and wrinkle-resistant properties.

Provides a balanced texture on both sides of the fabric, enhancing comfort and aesthetic appeal.

Multi-layered and Thick Fabrics:

The high-foot design allows knitting of thicker materials that provide warmth and durability, ideal for school uniforms worn in various climates.

The 36-inch, 32-gauge, 108 feeders ordinary double jersey circular knitting machine is widely used in the production of fine, high-density double-knit fabrics. It is suitable for various applications acros...

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and efficiency. Its unique f...

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitting, it offers high-s...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational stability. Ensures e...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control systems and double-...

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15