![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

34‘’12G72F

Model:

34‘’12G72F

![]() NET Weight:

2Ttons

NET Weight:

2Ttons

![]() Diameter:

1.9m

Diameter:

1.9m

![]() Gauge:

12

Gauge:

12

![]() Feeder:

72

Feeder:

72

![]() Certification:

ISO,CE

Certification:

ISO,CE

![]() Applicable Yarn Material:

Sun

Applicable Yarn Material:

Sun

![]() RPM:

20

RPM:

20

![]() Wooden Box Size:

2.4m*3m

Wooden Box Size:

2.4m*3m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

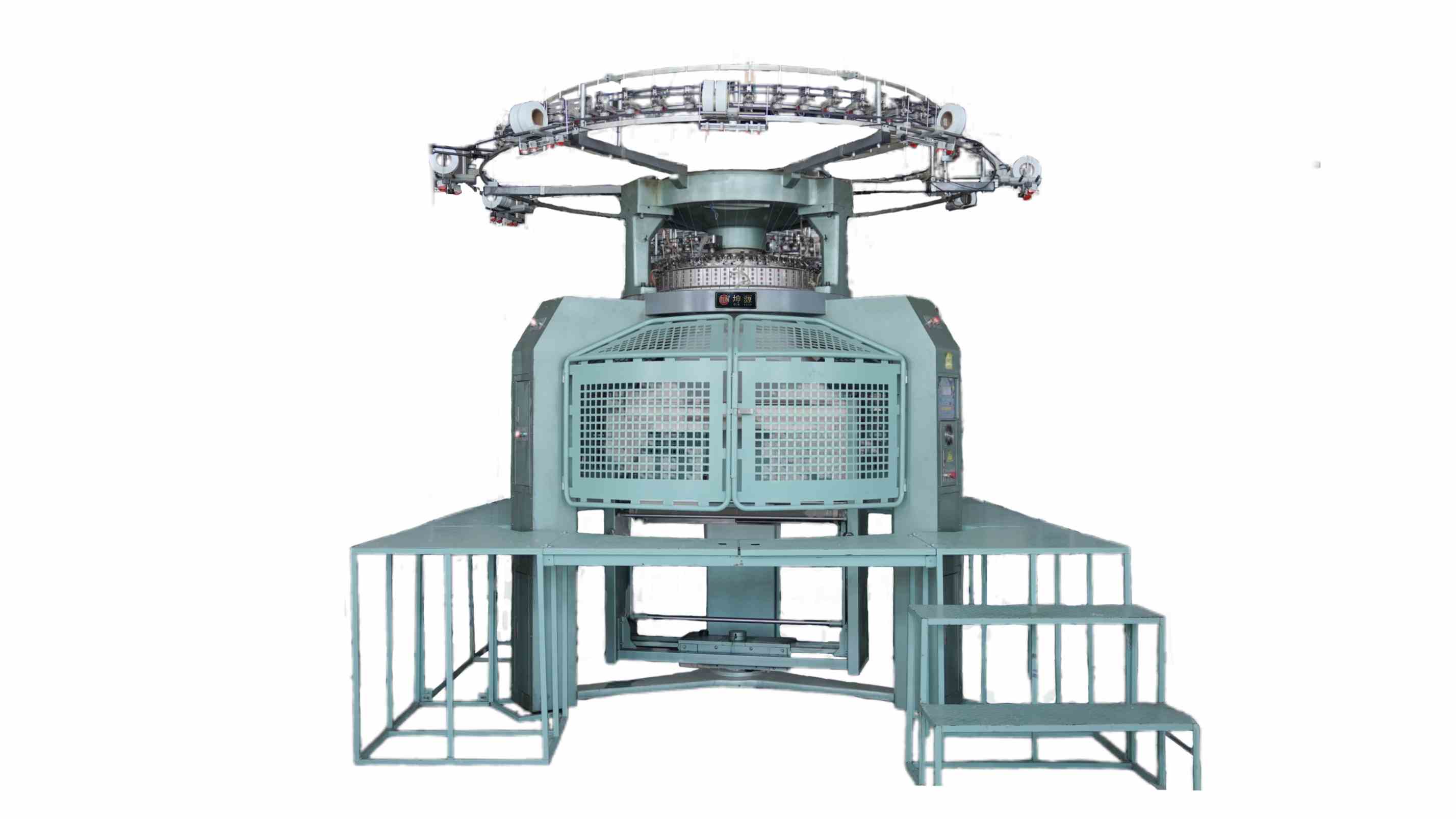

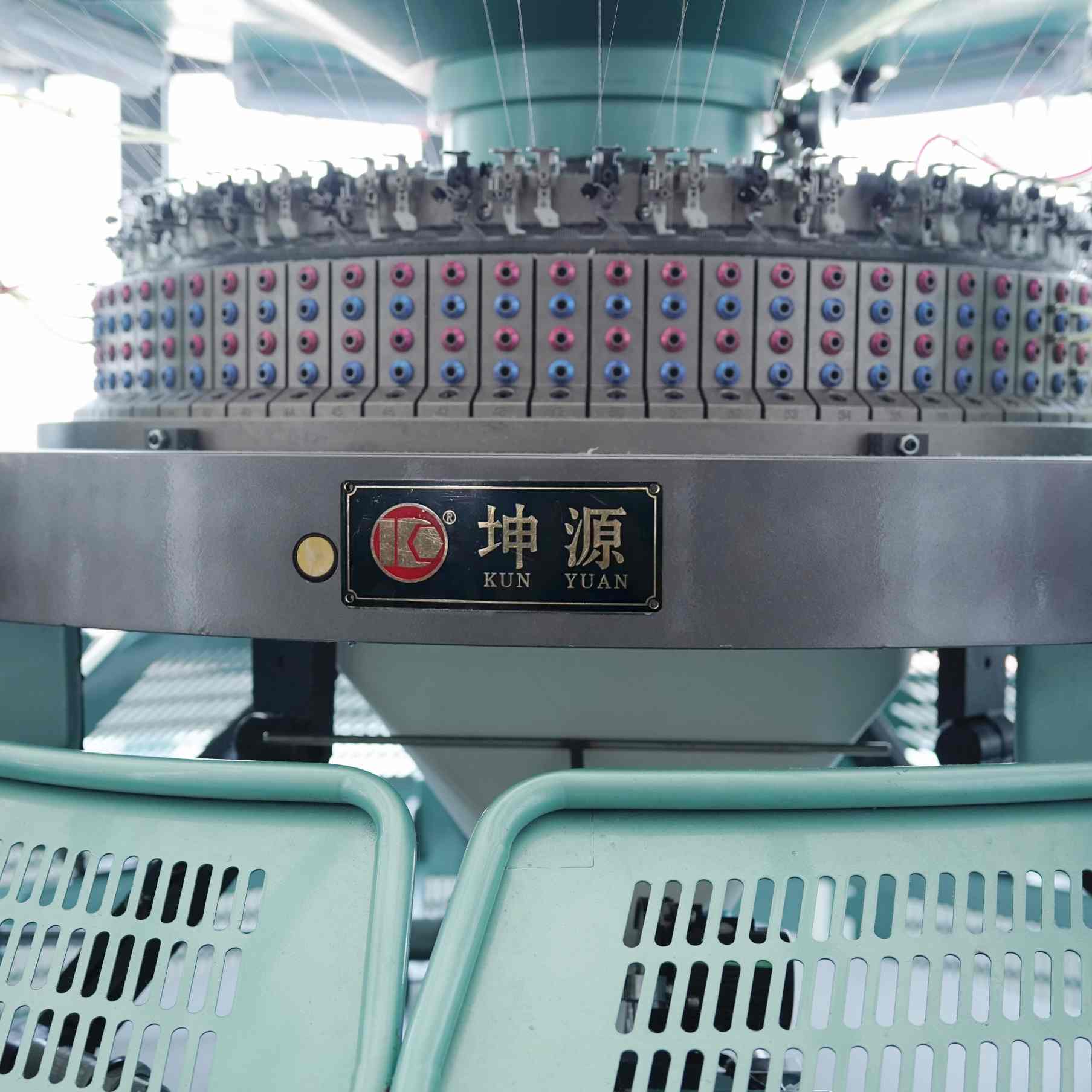

Double-sided Thread Knitting Machine Technical Specifications

Model: 34'' 12G 72F

Diameter: 1.9 meters

Gauge: 12G (12 needles per inch)

Number of Feeders: 72 feeders

Weight: 24 tons

Speed: 20 revolutions per minute (RPM)

This machine is designed for the efficient production of double-sided knitted fabrics with medium to coarse gauge, suitable for applications requiring durability and texture. The 12-gauge needle system enables the knitting of thicker, more robust fabrics, ideal for sectors such as footwear, clothing, and automotive interior textiles. Equipped with 72 feeders, the machine ensures continuous yarn supply for consistent fabric quality. The large 1.9-meter diameter and heavy-duty construction provide operational stability, while the 20 RPM speed offers a balanced output between productivity and precision.

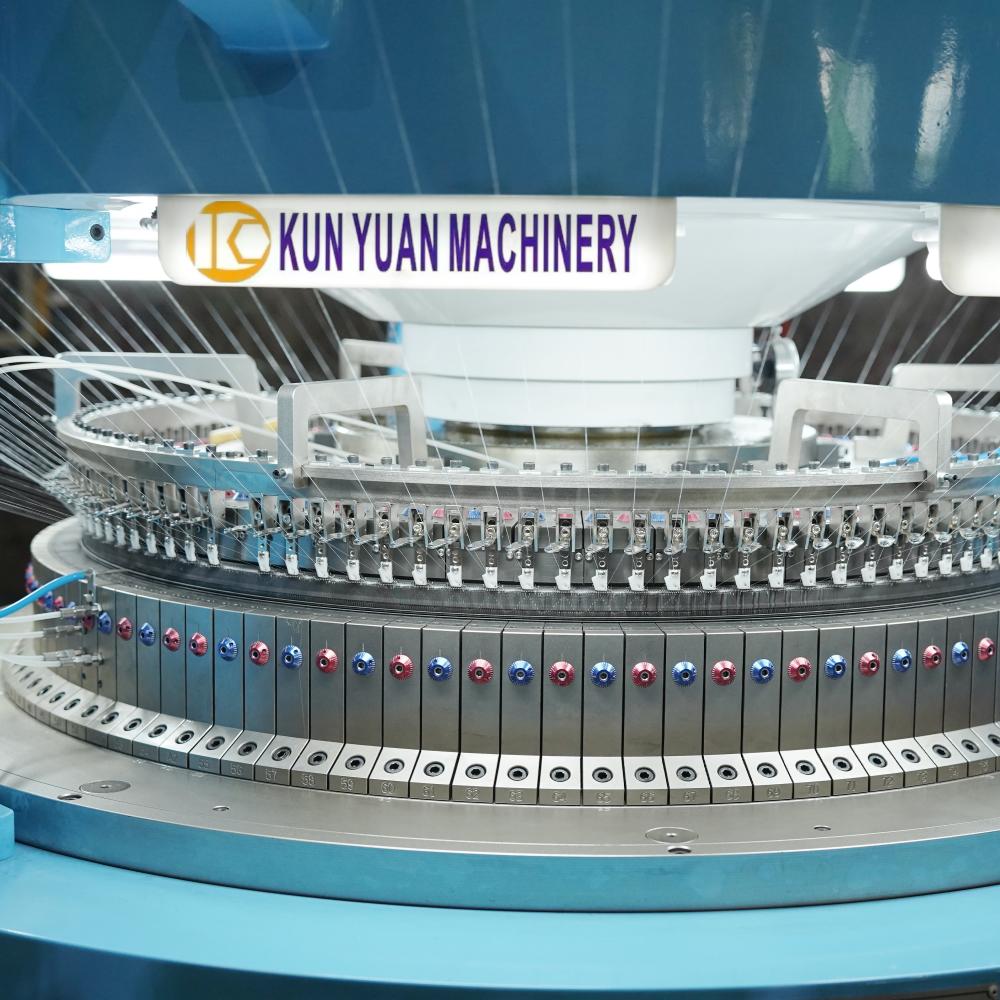

|

Item |

Details |

|---|---|

| Cylinder Diameter | 34 inches (approx. 864 mm) |

| Gauge | 28G (fine knitting gauge) |

| Number of Feeders | 72 feeders |

| Knitting Type | Double Jersey (Interlock, Rib, etc.) |

| Main Motor Power | 5.5 kW (Inverter controlled) |

| Control System | PLC with Touchscreen (HMI interface) |

| Take-Down System | Pneumatic Open-Width Fabric Take-Down |

| Rolling Options | Center rolling or open-width rolling |

| Lubrication | Automatic centralized lubrication |

| Production Speed | 20–30 RPM (depending on yarn/fabric) |

| Yarn Compatibility | Cotton, Polyester, Spandex, etc. |

| Machine Frame | Heavy-duty aluminum alloy structure |

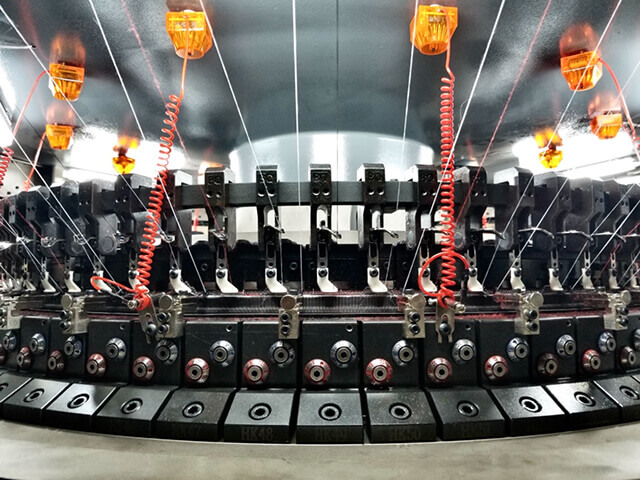

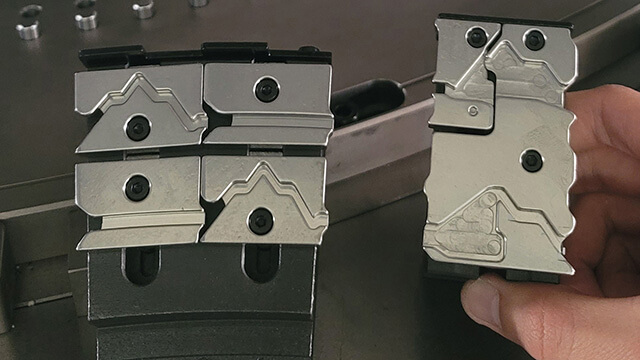

Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine

Function

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and efficiency. Its unique feature is the interchangeable needle bed system, allowing it to switch seamlessly between 12-pin and 36-pin configurations based on production needs.

Double-sided Fabric Production:

Capable of knitting fabrics with finished surfaces on both sides, enhancing durability, texture, and visual appeal.

Interchangeable Needle Beds:

Allows for quick changeover between 12-pin and 36-pin setups, providing flexibility in fabric design, density, and weight.

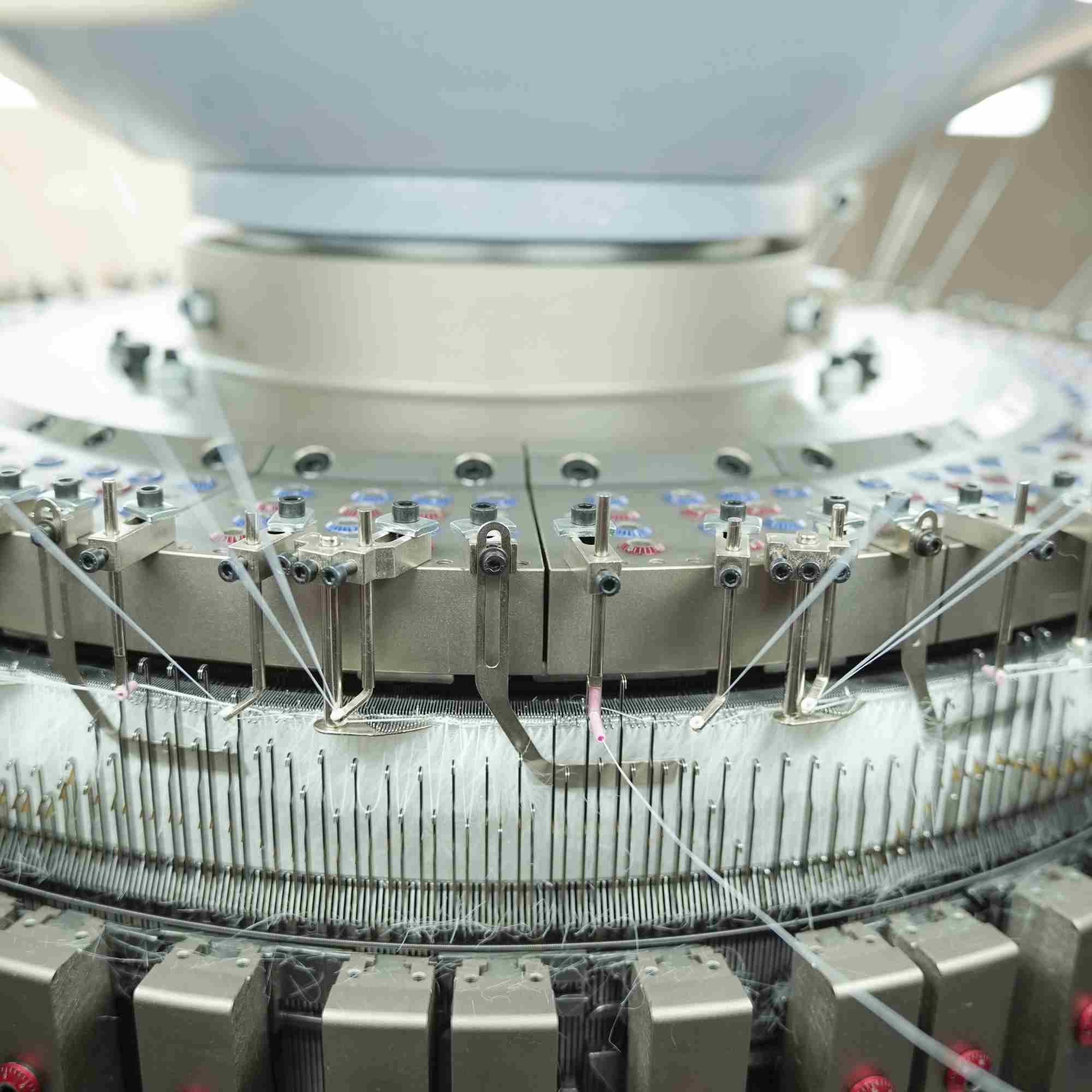

Precision Knitting of Threaded Fabrics:

Optimized for knitting complex threaded structures used in fashion, sportswear, and technical textiles.

High Efficiency and Versatility:

Enables manufacturers to produce a wide range of fabric types without needing multiple machines, reducing downtime and increasing productivity.

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and efficiency. Its unique f...

This machine is engineered for precision knitting of high-density threaded fabrics, particularly for garment components such as collars, cuffs, and waistbands. The 60-gauge configuration provides an ultra-...

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elastic fabrics. The 84 fe...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for producing a variety o...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to interchange threads ...

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16