![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

38 ''24 G84F

Model:

38 ''24 G84F

![]() NET Weight:

2tons

NET Weight:

2tons

![]() Diameter:

2m

Diameter:

2m

![]() Gauge:

24

Gauge:

24

![]() Feeder:

84

Feeder:

84

![]() Certification:

CE,ISO

Certification:

CE,ISO

![]() Applicable Yarn Material:

Sun

Applicable Yarn Material:

Sun

![]() RPM:

20

RPM:

20

![]() Wooden Box Size:

2.5m

Wooden Box Size:

2.5m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

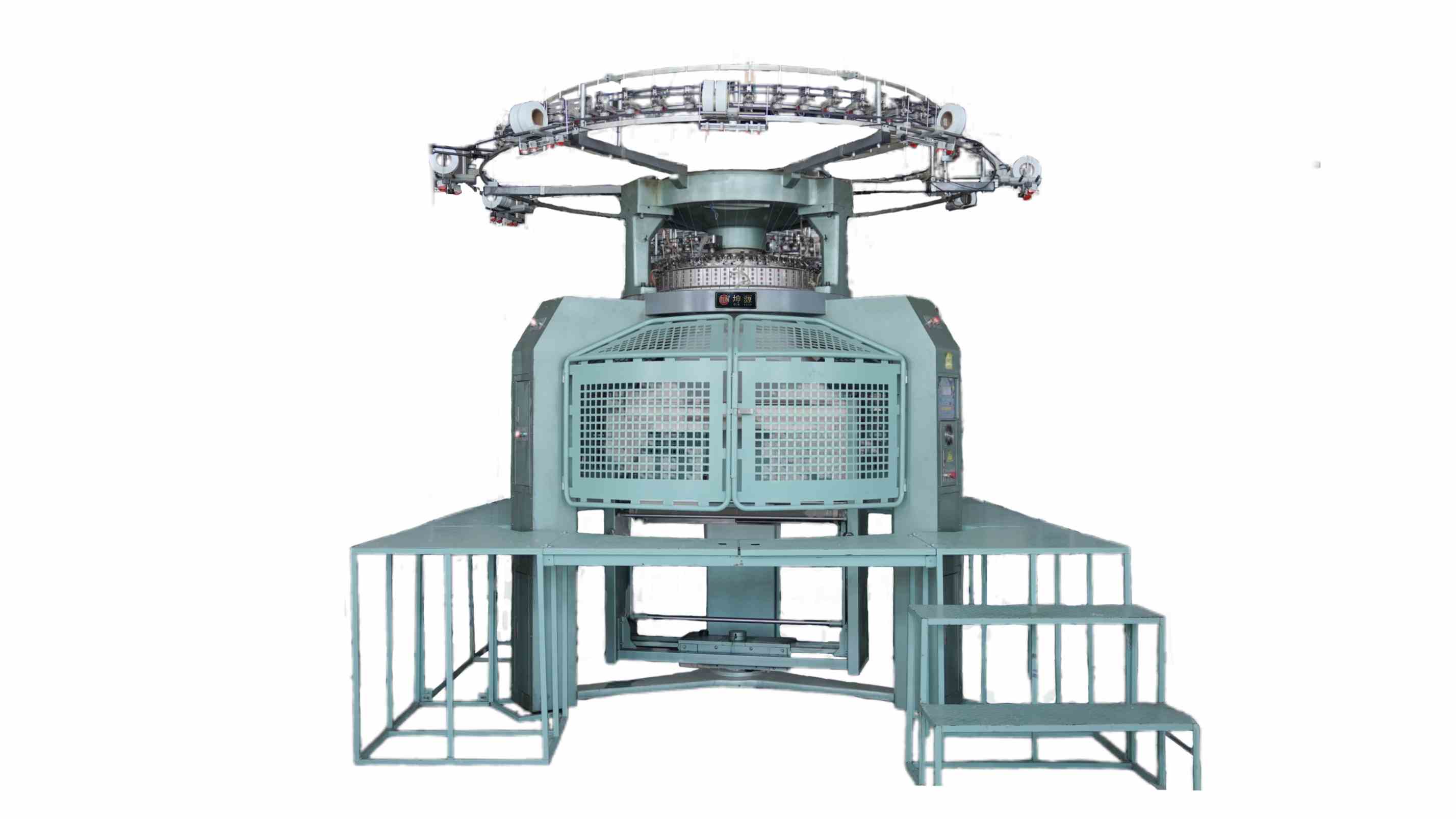

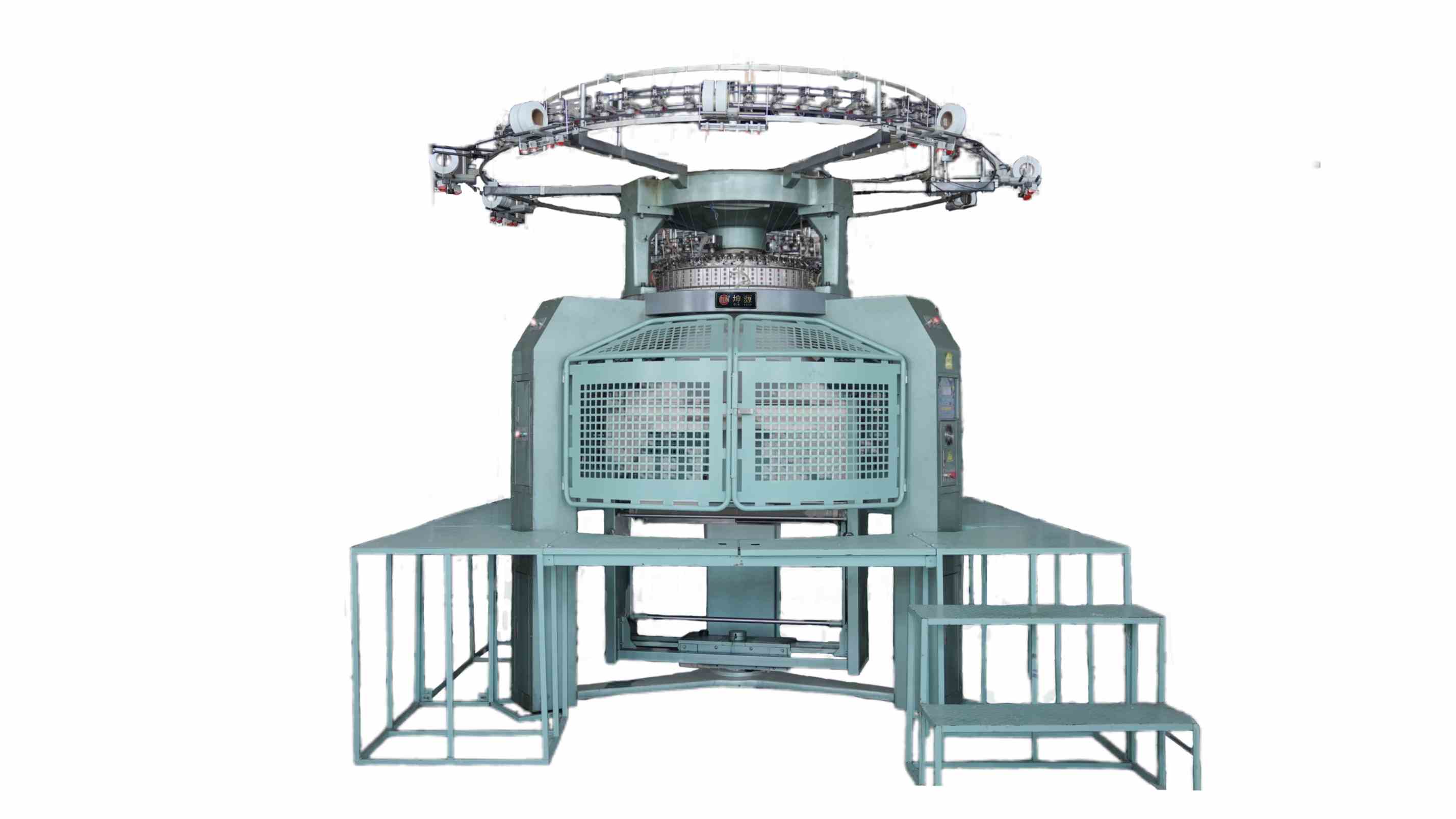

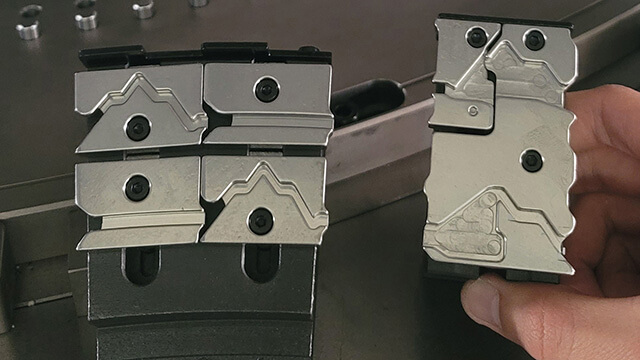

Double-sided Thread Machine Technical Specifications

Model: 38'' 24G 84F

Diameter: 2 meters

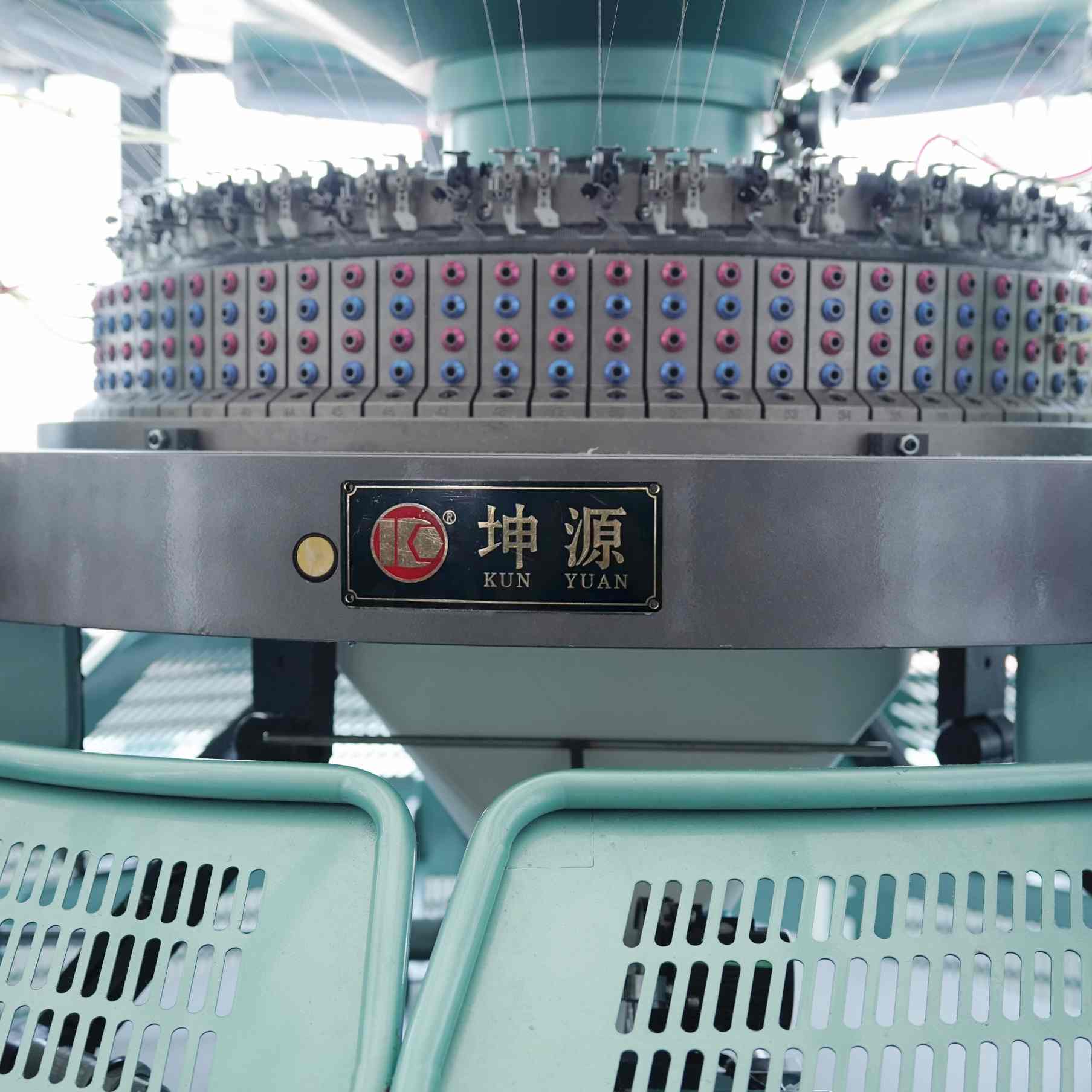

Gauge: 24G (24 needles per inch)

Number of Feeders: 84 feeders

Weight: 2 tons

Speed: 20 revolutions per minute (RPM)

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elastic fabrics. The 84 feeders ensure continuous yarn supply for balanced and uniform fabric formation, while the 2-meter diameter provides a large working area for increased productivity. Operating at 20 RPM, it balances speed and fabric quality, making it ideal for producing garments such as sportswear, undergarments, and ribbed knitwear.

| Parameter | Details |

|---|---|

| Cylinder Diameter | 38 inches (approx. 965 mm) |

| Gauge | 24G (medium gauge) |

| Number of Feeders | 84 Feeders |

| Knitting Type | Double-sided (Double Jersey, Rib, Interlock) |

| Main Motor Power | 5.5 kW (variable frequency drive) |

| Control System | PLC with Touchscreen Interface |

| Take-Down System | Pneumatic open-width take-down |

| Rolling Options | Center rolling / open-width rolling |

| Lubrication System | Automatic centralized lubrication |

| Production Speed | 20–30 RPM (depending on yarn/fabric) |

| Applicable Yarn Types | Cotton, Polyester, Spandex, Blends |

| Machine Frame | Heavy-duty aluminum alloy |

| Weight | Approx. 2800 kg |

Double-sided Thread Machine – Function

The Double-sided Thread Machine is a specialized textile machine designed for knitting and processing double-sided fabrics. Its primary function is to interlace yarns on both the front and back sides of the fabric simultaneously, resulting in thicker, more durable textiles with excellent elasticity and structure.

Double-sided Fabric Knitting:

Produces fabrics with identical or different textures on both sides, improving versatility and comfort.

High Elasticity Support:

Well-suited for working with spandex fabrics, allowing the production of stretchable textiles ideal for sportswear and fitted garments.

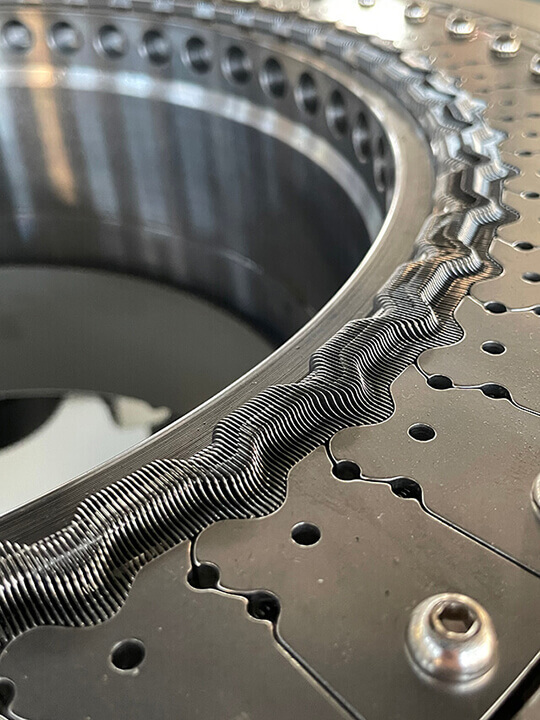

Precision Threading for Ribbed Structures:

Capable of creating threaded or ribbed cloth, offering excellent shape retention and a snug fit, commonly used in cuffs, collars, and waistbands.

Stable Production of Plain Cloth:

Efficiently handles double-sided plain cloth, ensuring uniform texture and high fabric strength for various apparel and textile uses.

Typical Applications:

Casualwear and activewear

Undergarments and leggings

Rib-knit components for garments

Stretchable and breathable fabric products

This machine is ideal for manufacturers looking to produce high-quality, elastic, and structured fabrics with consistent double-sided characteristics.

Let me know if you'd like a version focused on technical marketing or for inclusion in a user manual.

Application of the Double-sided Thread Machine

The Double-sided Thread Machine is widely used in the garment industry for producing high-quality, durable, and stretchable fabrics. It is specifically designed to knit double-sided fabrics that feature identical or complementary surfaces on both sides, making them ideal for a wide range of clothing applications.

Casualwear and Everyday Clothing

Used to produce soft and comfortable double-sided plain cloth for items like t-shirts, polo shirts, and loungewear.

Offers enhanced breathability and wear resistance.

Sportswear and Activewear

Ideal for knitting spandex or stretch fabrics that require high elasticity and shape recovery.

Commonly used in leggings, yoga pants, and performance tops.

Ribbed Garment Components

Produces threaded or ribbed cloth, widely used for cuffs, waistbands, collars, and hems.

Ensures elasticity and a snug fit in key areas of garments.

Undergarments and Base Layers

Creates soft, skin-friendly fabrics suitable for underwear, thermal wear, and inner layers.

Offers warmth, flexibility, and comfort.

Children’s Clothing

Used to make gentle, durable fabrics suitable for sensitive skin and high-movement garments like baby rompers and kids’ sets.

Summary:

The Double-sided Thread Machine plays a crucial role in modern apparel production, providing versatile fabric solutions that meet the demands of comfort, elasticity, and durability. Its ability to work with a variety of yarns and fabric types makes it a valuable asset for clothing manufacturers focused on quality and performance.

Let me know if you’d like this in a presentation format or as part of a product brochure

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitting, it offers high-s...

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elastic fabrics. The 84 fe...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for producing a variety o...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational stability. Ensures e...

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11