![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

34‘’28G72F

Model:

34‘’28G72F

![]() NET Weight:

1800–3000 kg (varies by size)

NET Weight:

1800–3000 kg (varies by size)

![]() Diameter:

26

Diameter:

26

![]() Gauge:

14G–32G (adjustable based on fabric requirement)

Gauge:

14G–32G (adjustable based on fabric requirement)

![]() Feeder:

52F – 84F (depends on cylinder size)

Feeder:

52F – 84F (depends on cylinder size)

![]() Certification:

CE,ISO

Certification:

CE,ISO

![]() Applicable Yarn Material:

Cotton, Polyester, Spandex, Rayon, Bamboo Fiber, etc.

Applicable Yarn Material:

Cotton, Polyester, Spandex, Rayon, Bamboo Fiber, etc.

![]() RPM:

16–35 rpm

RPM:

16–35 rpm

![]() Wooden Box Size:

2.5m

Wooden Box Size:

2.5m

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

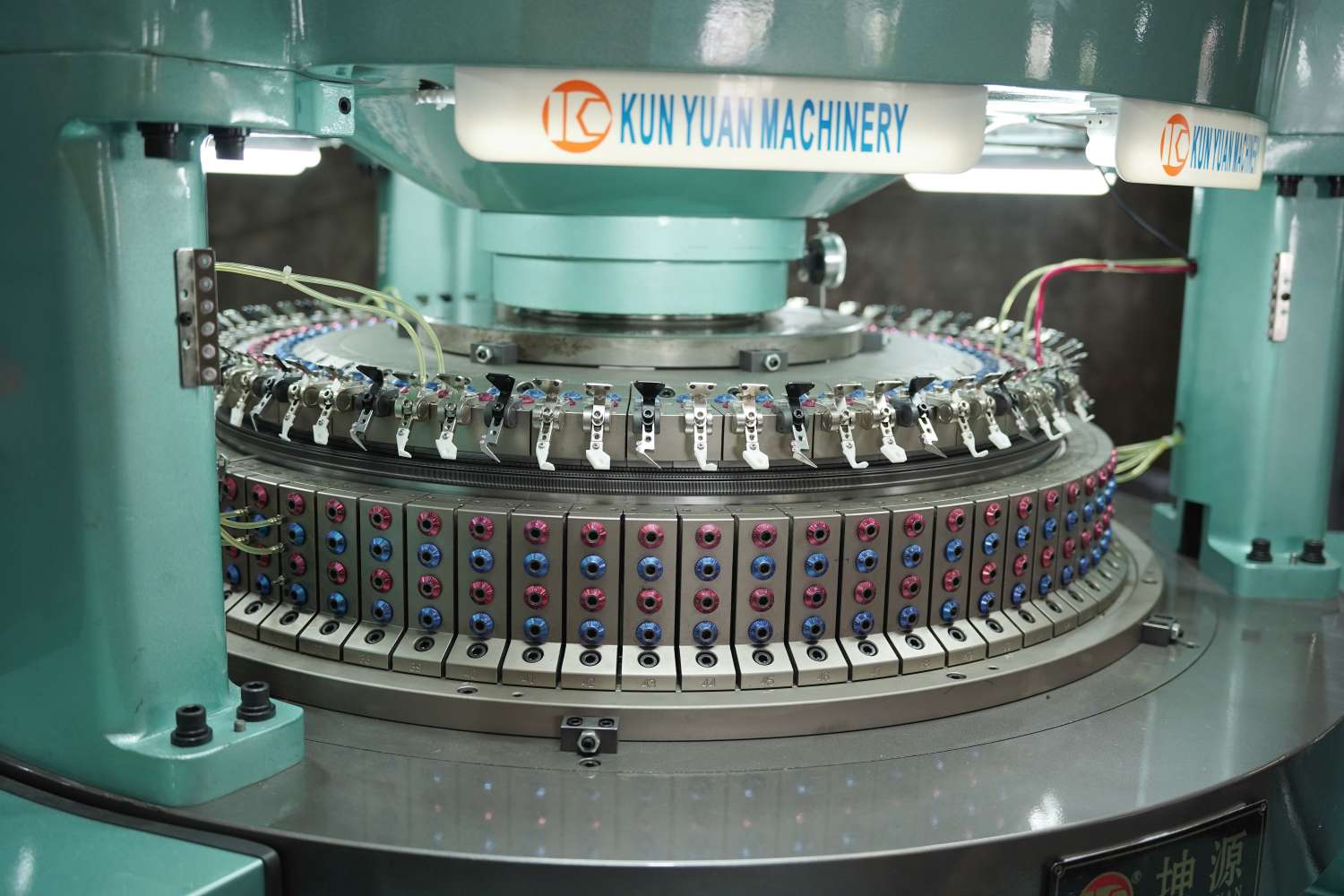

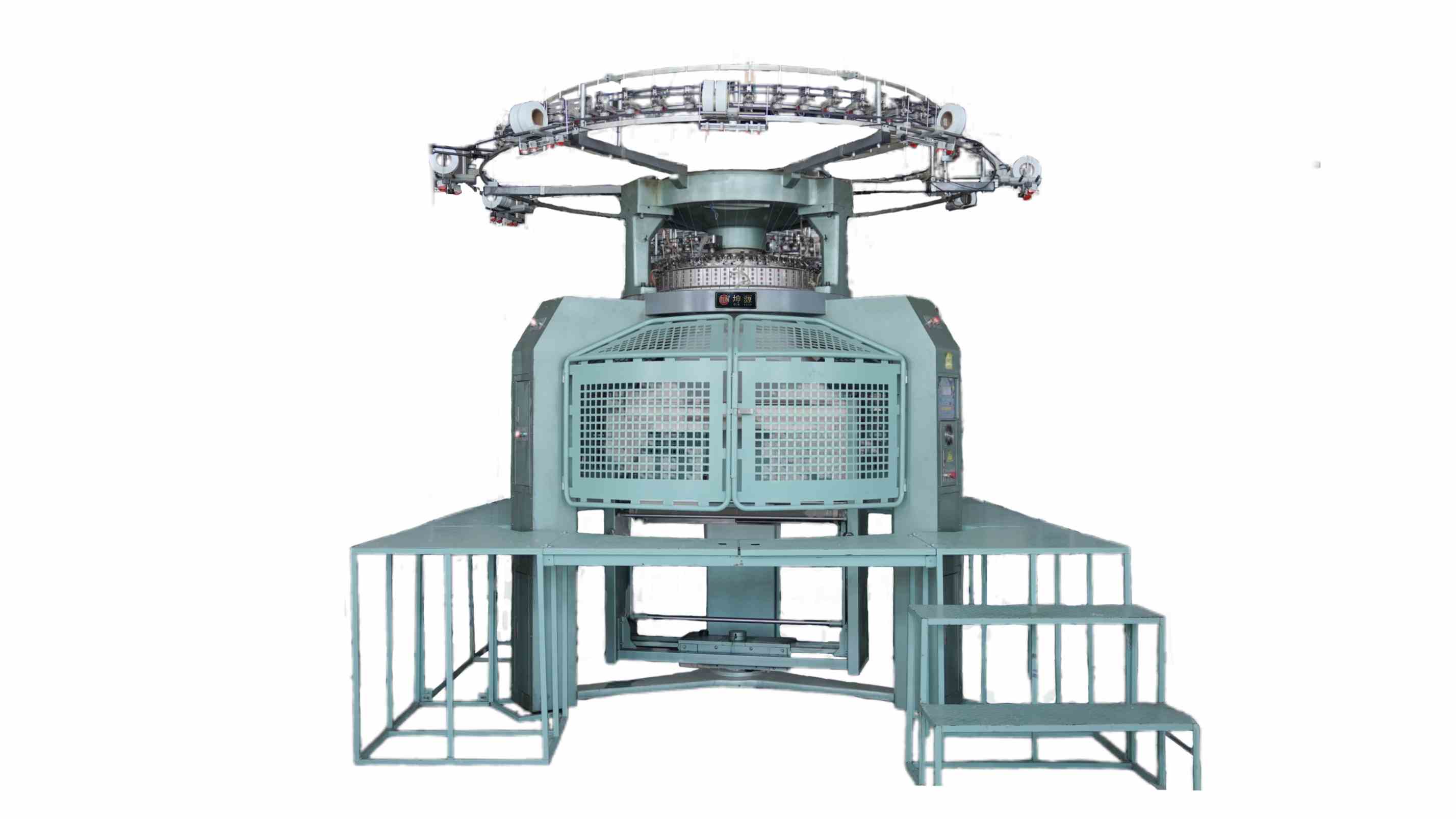

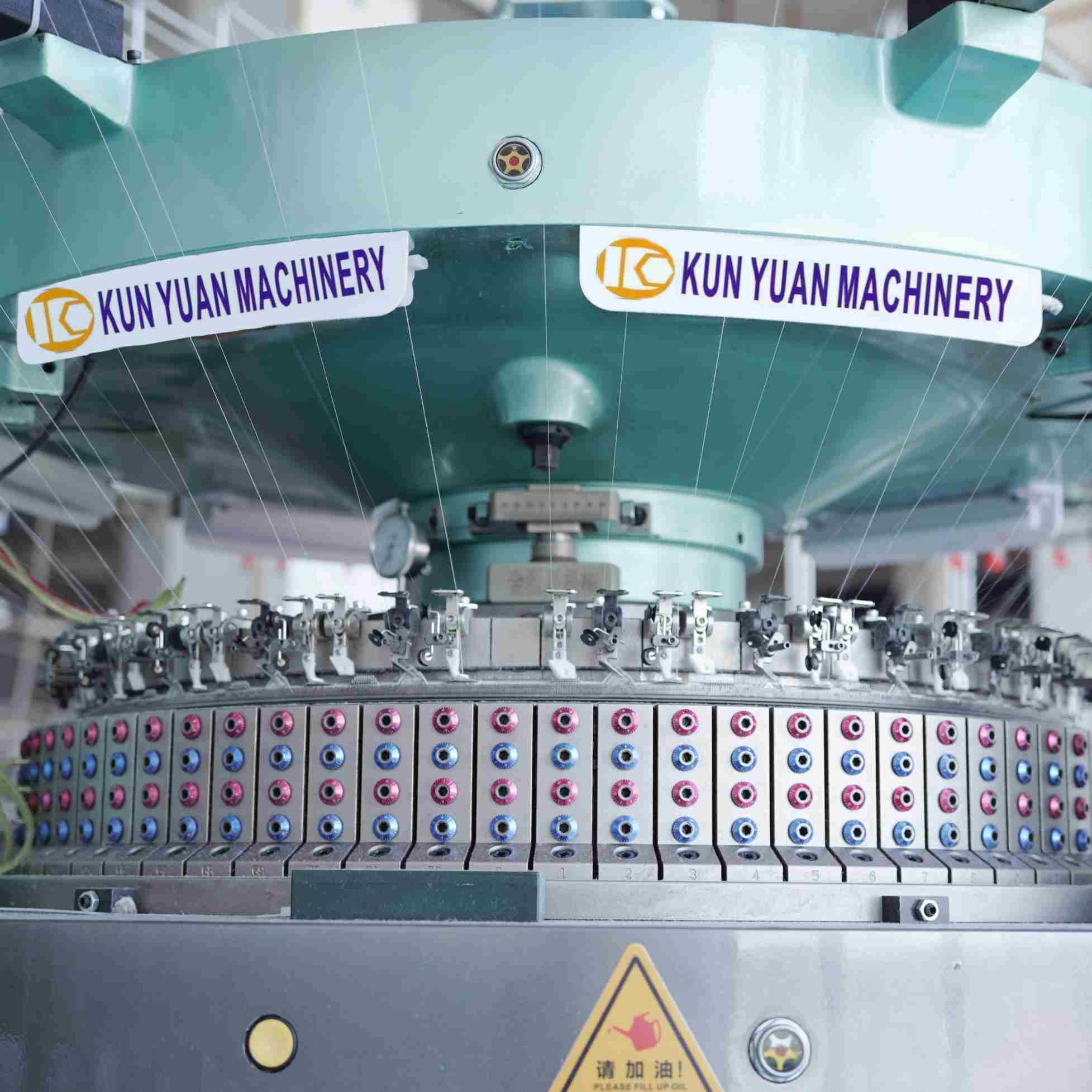

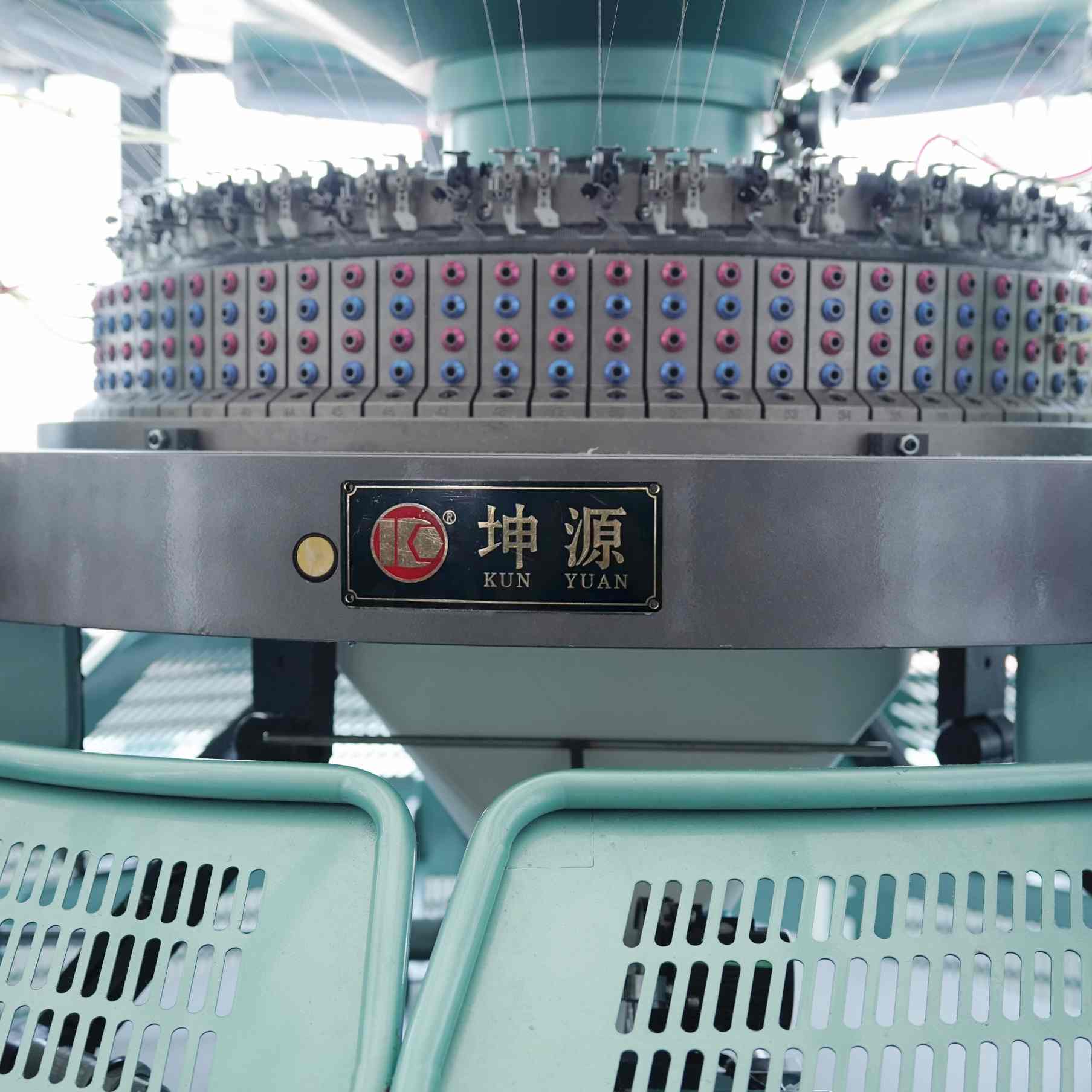

Machine Type

Double‑Side (Interlock/Double Jersey) circular knitting machine with pneumatic open‑width take‑up and slitting system – optimized for fabric flattening and clean edge finishing.

Cylinder Diameter

34″ (≈ 863 mm) – standard body‑size diameter common in this class.

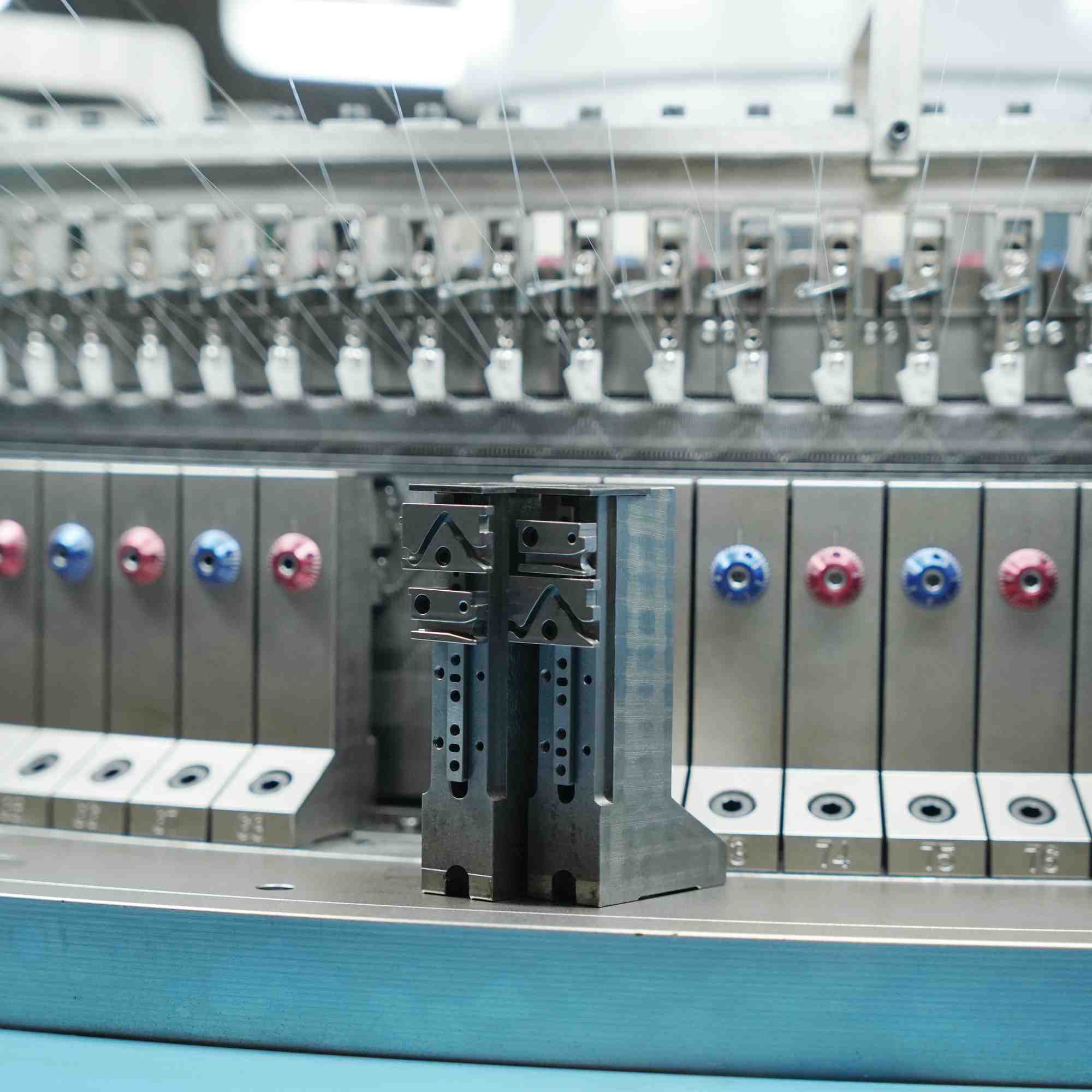

Gauge

28G (28 needles per inch) – medium‑fine gauge producing smooth, drapey interlock fabric.

Feeders

72 feeders – balanced for 28G, providing even yarn feeding and high efficiency.

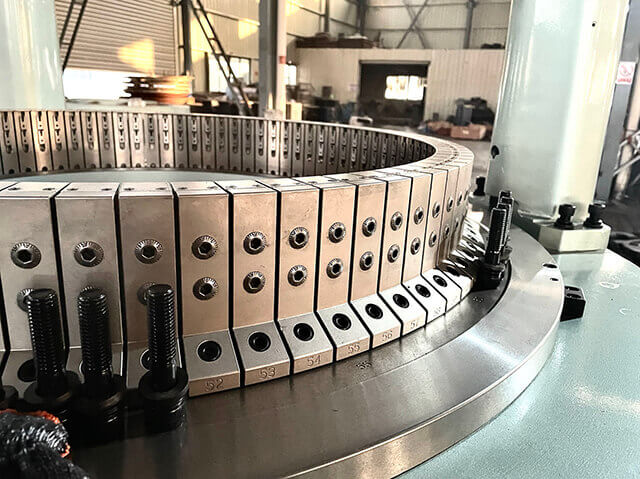

Needle Count

~2,136 needles total (single‑side 1,068; double‑side counts ~2× needles).

Motor & Drive

Typically driven by 5.5–7.5 kW (~7.5–10 HP) (~380 V 3‑phase) motor via inverter for speed control.

Knitting Speed

Operates between 15–30 RPM, depending on yarn, gauge, and fabric style.

Fabric Take‑Up

Pneumatic open‑width take‑up maintains width and eliminates curl, paired with slitter for clean raw edge.

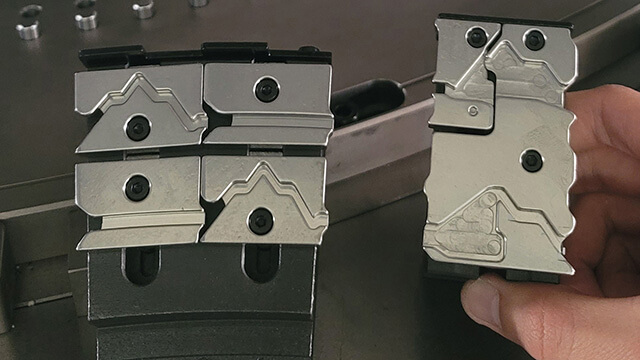

Frame & Precision

Heavy-duty steel chassis, oil-immersed needle bed, Japanese stainless cylinder; high-precision cams, electronic or air lubricators.

Control & Safety

Equipped with RPM counters, broken-needle sensors, positive feeders, frequency inverter, dust/fan protection.

Classic Interlock/Double Jersey

Smooth, reversible, no curl, ideal for T-shirts, underwear, sportswear.

Rib & Twill Structures

Achieved with adjustable cam tracks for 1×1, 2×2 rib, piqué, twill, waffle textures.

Air-layer/Bubble Fabrics

Volumized textures like air-layer, bubble, and pique, generated by cam settings.

High-Pile / Velvets (Optional Jacquard Add-on)

With jacquard and cutter attachments, can produce loop-cut fleece: coral fleece, velvet, etc. Example images show coral velvet textures.

| Item | Specification Details |

|---|---|

| Machine Type | Double-Side Pneumatic Opening Width Circular Knitting Machine |

| Cylinder Diameter | 34 inches (≈ 863 mm) |

| Gauge | 28G (28 needles per inch) |

| Number of Feeders | 72 feeders |

| Number of Needles | Approx. 2,136 needles (based on 28G for 34″ cylinder) |

| Drive Motor Power | 5 – 7.5 HP (depends on fabric structure model) |

| Knitting Speed | Up to 20 – 23 RPM |

| Production Output | Approx. 380 – 420 kg per 24 hours (based on 30s cotton yarn) |

| Power Consumption | Approx. 132 kW |

| Machine Footprint | Approx. 6.5 m (L) × varies by model width |

| Fabric Take-Up System | Pneumatic open-width take-up with fabric slitting device |

| Control System | Frequency-controlled motor with pneumatic control for take-up |

| Applicable Fabrics | Rib fabric, double jersey, mesh, interlock, Lycra-based fabrics |

| Frame Structure | Heavy-duty steel frame with precise alignment for high-speed operation |

| Optional Features | Lycra attachment, automatic fabric rolling, fabric inspection system |

Double-Sided Knitting Capability

Simultaneously knits both sides of the fabric, ideal for producing double jersey, interlock, rib, air layer, and other structured fabrics.

Enhances productivity and fabric stability.

Pneumatic Fabric Opening System

Uses a pneumatic mechanism to automatically open the fabric width during production.

Effectively reduces wrinkles and prevents edge curling, ensuring flat and smooth fabric output.

Automatic Fabric Rolling System

Automatically adjusts rolling tension to ensure even and smooth fabric rolls.

Supports various rolling options such as center rolling or open-width rolling to meet different processing requirements.

This machine is engineered for precision knitting of high-density threaded fabrics, particularly for garment components such as collars, cuffs, and waistbands. The 60-gauge configuration provides an ultra-...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot openings (greater sp...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Provides a wide knitting...

Its user-friendly interface allows quick adjustments and smooth operation, making it ideal for both beginners and experienced operators.2025-07-11

The Double-sided Thread Interchangeable Circular Knitting Machine is efficient, durable, and delivers smooth, high-quality fabric production with reliable performance.2025-07-16

The Ordinary Double Jersey Knitting Machine excels in versatility, It offers stable performance, easy operation, and efficient production, making it ideal for various double-knit fabric applications.2025-07-15

The Pneumatic Circular Knitting Machine offers stable performance, smooth operation, and high precision, ensuring consistent fabric quality.2025-07-16