The client had been facing increasing demand for high-quality terry fabrics, which their existing machines were unable to meet efficiently. Their limitations in design flexibility, speed, and quality control were beginning to impact growth potential. Recognizing the need for innovation, the company decided to invest in a more advanced, versatile solution.

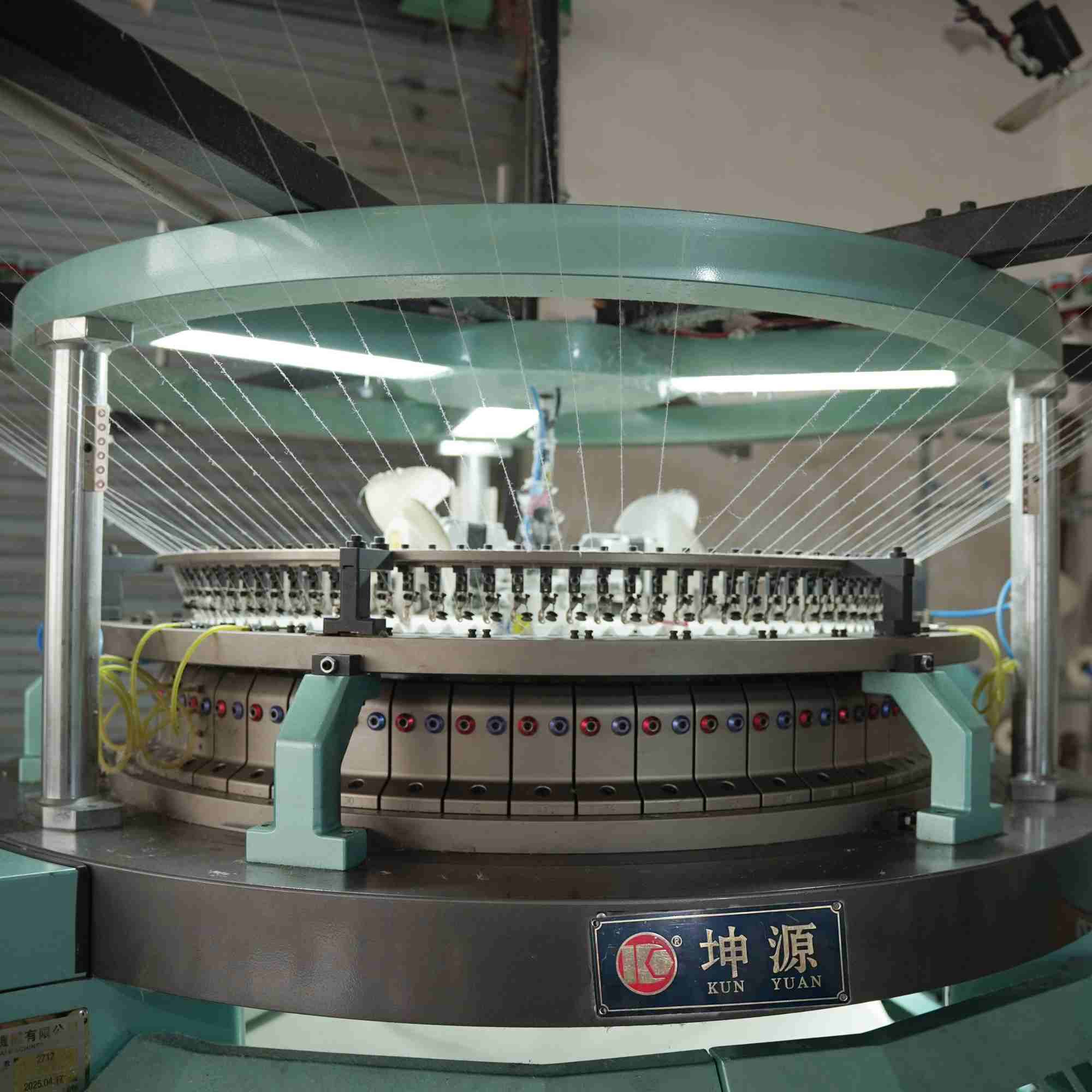

After detailed market research and performance evaluations, the client opted for a computerized Terry Jacquard Circular Knitting Machine, designed specifically to handle complex terry fabric designs with enhanced precision and output.

The client partnered with a leading textile machinery supplier, known for delivering reliable, high-performance knitting solutions. From procurement to installation, the supplier provided comprehensive support, including system integration and operator training, ensuring a seamless transition to the new machine.

The machine was customized to align with the client’s production needs, incorporating:

Computerized controls for real-time process management

Jacquard functionality for high-detail design execution

Efficiency-boosting features for optimized operation

With computerized automation, the client achieved faster production cycles and reduced downtime. This allowed them to efficiently manage large-scale orders and meet tight delivery schedules.

The jacquard system enabled the production of complex, customized terry fabric designs, giving the client the ability to expand their product offerings and cater to niche and premium markets.

Automated precision in the knitting process ensured consistent, defect-free fabric production. This improved product reliability and minimized returns or reworks, thereby strengthening customer trust.

The machine’s optimized resource usage led to reduced energy consumption and minimal material waste. In addition, the lower need for manual labor and reduced error rates contributed to noticeable cost reductions.

The adoption of the computerized Terry Jacquard Circular Knitting Machine has had a transformational impact on the client’s operations. They are now capable of:

Meeting rising market demand

Delivering superior-quality fabrics

Offering unique, high-value designs

Operating with improved cost efficiency

This investment not only boosted their profitability but also positioned them as an innovation-driven leader in the Thai textile industry.

The case of this Thailand-based textile manufacturer demonstrates the strategic value of embracing advanced machinery in a competitive industry. The computerized Terry Jacquard Circular Knitting Machine served as a powerful tool for enhancing production efficiency, design flexibility, and fabric quality.

By partnering with a trusted machinery supplier and investing in cutting-edge solutions, the client successfully elevated their capabilities and market position—underscoring the importance of technological innovation in driving sustainable growth in the textile sector.