![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

Model:

![]() NET Weight:

4 tons

NET Weight:

4 tons

![]() Diameter:

30’’

Diameter:

30’’

![]() Gauge:

8G-24G

Gauge:

8G-24G

![]() Feeder:

54F

Feeder:

54F

![]() Certification:

CE,ISO

Certification:

CE,ISO

![]() Applicable Yarn Material:

Cotton, Chemical fiber, Blended yarn, Silk and wool etc.

Applicable Yarn Material:

Cotton, Chemical fiber, Blended yarn, Silk and wool etc.

![]() RPM:

15-30rpm

RPM:

15-30rpm

![]() Wooden Box Size:

2.25M*2.23M*2.25M

Wooden Box Size:

2.25M*2.23M*2.25M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

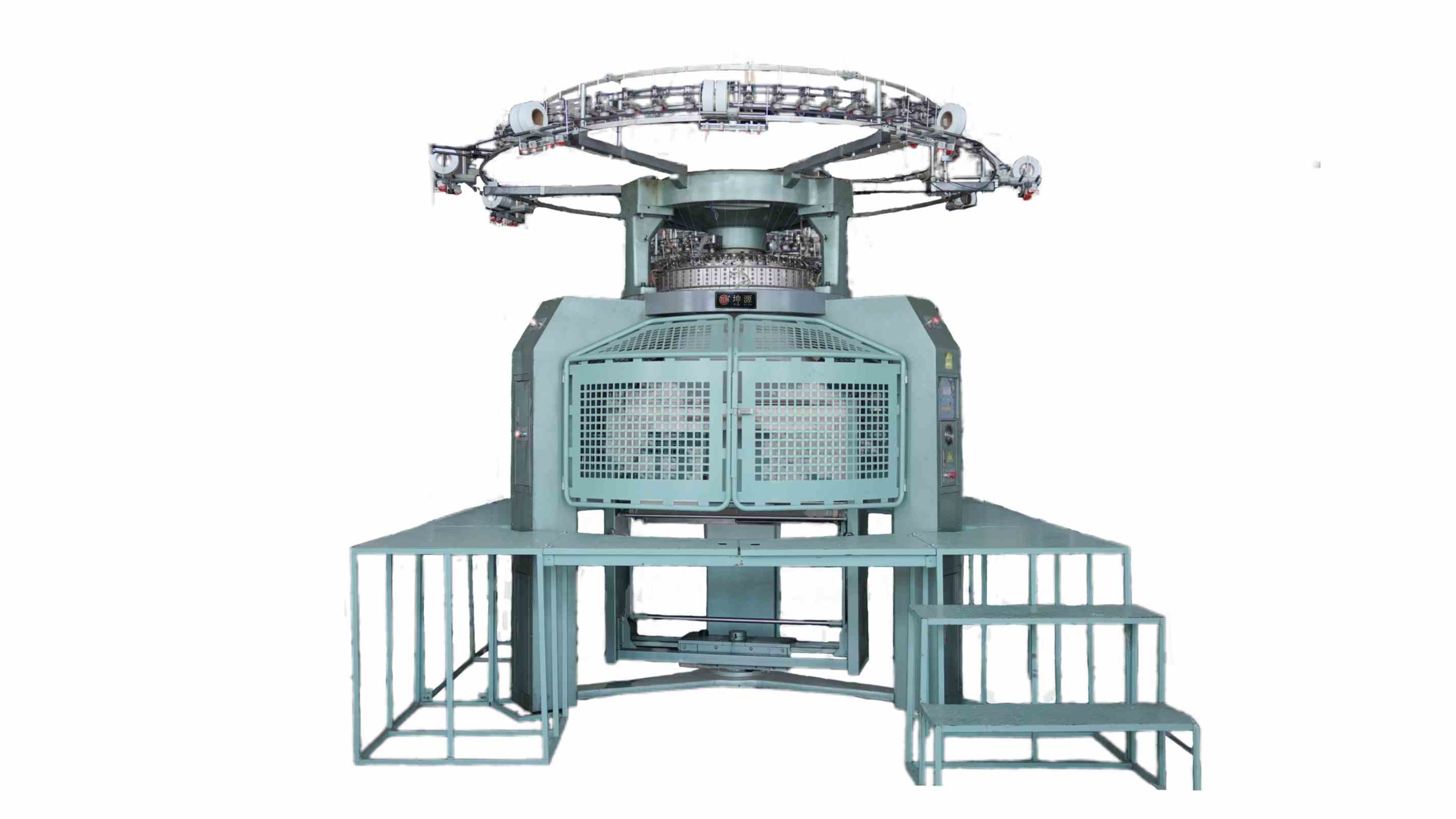

The Rib Double Jersey Circular Knitting Machine is a high-performance textile machine designed specifically for producing rib fabrics with double jersey structures. Built with advanced technology and precision components, it ensures smooth, efficient operation suitable for both small and large-scale textile manufacturers. This versatile machine is ideal for creating high-quality rib fabrics used in a variety of applications, including collars, cuffs, and elastic sportswear materials.

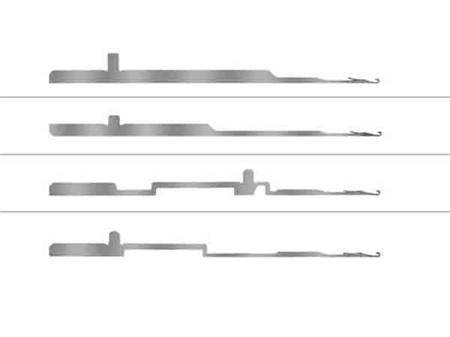

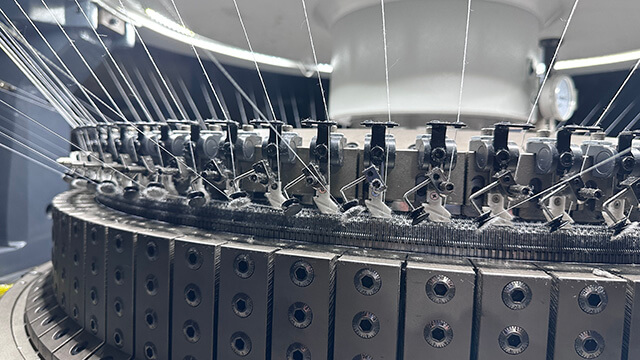

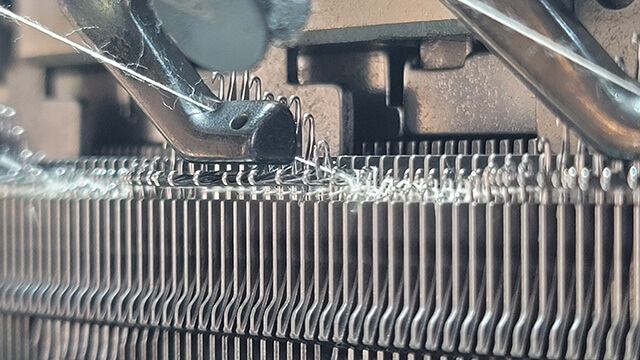

Double Needle Beds

Equipped with double needle beds to facilitate seamless production of double jersey rib fabrics.

High-Speed Operation

Capable of running at high speeds to boost productivity and meet the demands of rapid textile manufacturing.

Wide Gauge Range

Offers flexibility with a broad gauge range, enabling diverse fabric design and production options.

User-Friendly Interface

Features an intuitive control panel for easy adjustment of machine settings and real-time monitoring of the knitting process.

Efficient Yarn Feeding System

Designed with a smooth and consistent yarn feeding mechanism to maintain fabric quality and production efficiency.

Proper Maintenance: Regular cleaning and lubrication are essential to maintain optimal machine performance and extend its lifespan.

Safety Measures: Operators must follow safety protocols and wear appropriate protective equipment during operation.

Yarn Tension: Correct yarn tension adjustment is critical to ensure fabric quality and prevent defects.

Suitable for manufacturing collars and cuffs.

Optional 1 or 2 track dial cams.

Optional 1, 2, or 4 track cylinder cams.

Capable of producing mini jacquard patterns by cam track adjustment.

Can incorporate spandex yarn to produce elastic fabrics ideal for sportswear.

| Diameter | Gauge | Feeder | RPM |

|---|---|---|---|

| 30’’ | 8G-24G | 54F/60F | 15-30 RPM |

| Model | Diameter | Net Weight Approx. | Gross Weight Approx. | Wooden Box Size (LWH) |

|---|---|---|---|---|

| kunyuan | 34’’ | 2.5T | 3.0T | 2.25m × 2.23m × 2.25m |

Main Functions:

1. Rib Fabric Production: The machine enables the production of high-quality ribbed fabrics with double jersey structures.

2. Fabric Design Flexibility: With its wide gauge range, the machine allows for various fabric design possibilities, including different stitch structures and patterns.

3. High-Speed Production: The high-speed operation of the machine ensures efficient and cost-effective fabric production.

In conclusion, the Rib Double Jersey Circular Knitting Machine is a versatile and efficient knitting machine that offers a wide range of features and benefits, making it suitable for various textile manufacturing applications.

Applications:

The Rib Double Jersey Circular Knitting Machine is widely used in the textile industry for producing ribbed fabrics for various applications, including:

1. Apparel: It can produce ribbed fabrics used in the manufacturing of t-shirts, sweaters, socks, and other knitted clothing items.

2. Home Textiles: This machine is suitable for producing ribbed fabrics used in the production of blankets, bedspreads, and upholstery materials.

3. Technical Textiles: It can also be utilized in the production of technical textiles, such as sportswear, medical textiles, and automotive fabrics.

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitting, it offers high-s...

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and efficiency. Its unique f...

Our client is a leading textile manufacturer in Saudi Arabia specializing in high-quality fleece fabrics for a variety of applications. With growing market demand and a commitment to operational excellence...

Introduction: Morocco has emerged as a significant player in the global textile and apparel industry. As the country continues to expand its manufacturing capabilities, it is crucial for local businesse...

The Rib Double Jersey Circular Knitting Machine delivers high-quality, elastic fabrics with precise rib and double jersey patterns. It runs smoothly, maintains stable tension, and ensures, it is ideal for professional textile manufacturing.2025-07-16

The support team was responsive, professional, and helpful throughout the process, ensuring a smooth and satisfying transaction.2025-07-11