This case highlights the successful implementation of a High Pile Cutting Circular Knitting Machine by a leading textile manufacturer in Belgium. Seeking to upgrade their production capabilities and respond to increasing market demand for premium high pile fabrics, the customer turned to our advanced solution to achieve operational efficiency, product quality, and innovation.

Prior to the investment, the customer faced several critical issues:

Inefficient Equipment: Existing knitting machines were not capable of efficiently handling high pile fabrics, resulting in inconsistent quality.

Manual Cutting Limitations: Manual cutting processes were time-consuming and prone to fabric wastage.

Production Bottlenecks: Slow output and rework due to quality inconsistencies affected profitability and lead times.

These challenges hindered their ability to scale operations and meet the growing demand for complex, high-pile textiles.

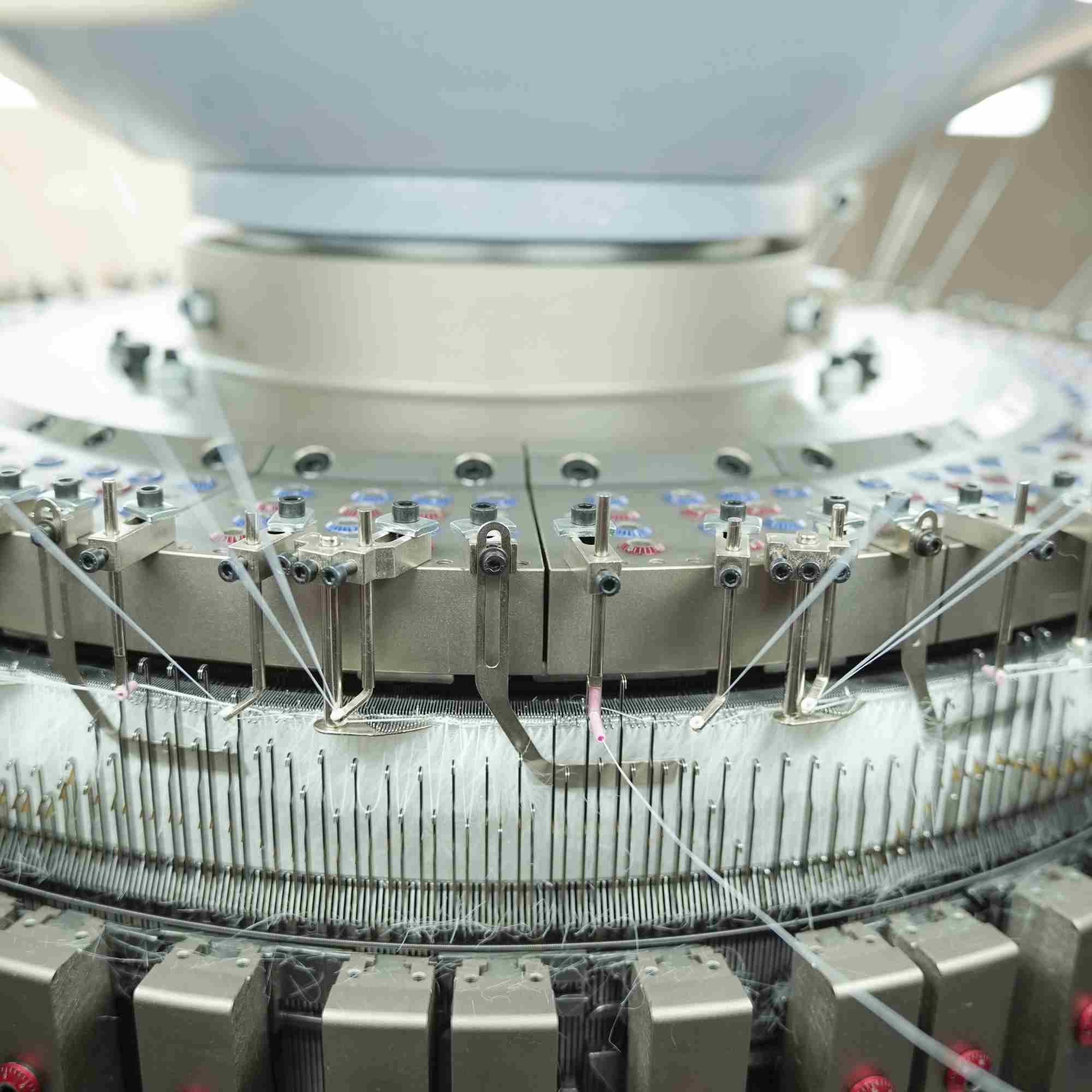

To overcome these issues, the customer invested in our High Pile Cutting Circular Knitting Machine, a state-of-the-art solution tailored for:

Consistent High Pile Fabric Production: With precise control over loop height and cutting accuracy.

Automated Cutting Technology: Minimizing manual intervention and fabric loss.

User-Friendly Interface: Allowing for intuitive operation and quick adaptation by machine operators.

The machine’s advanced features were key to streamlining the customer's production process while improving fabric consistency and expanding design capabilities.

The installation process included:

Comprehensive Training: Delivered by our technical team to ensure operators were fully equipped to run and maintain the machine.

Customization: The machine was fine-tuned to meet the client’s specific material and design needs.

Ongoing Technical Support: Ensuring minimal downtime and quick troubleshooting during the initial production phase.

This collaborative approach ensured a smooth and successful integration into the customer’s existing production workflow.

The results were both immediate and impactful:

Reduced Production Time

Minimized Waste

Enhanced Product Range

Improved Quality & Consistency

The Belgian client expressed high levels of satisfaction, citing:

Machine Reliability

Ease of Operation

Production Flexibility

Exceptional Technical Support

They reported improved customer feedback, increased orders, and stronger positioning in the competitive European textile market.

Challenges

Solution

Implementation

Results

Advanced automation and optimized knitting speed significantly cut down on overall production cycles.

The precision cutting mechanism reduced fabric waste, leading to better material efficiency and cost savings.

The ability to easily adjust patterns and fabric pile height opened new opportunities for product development and customization.

Uniform pile structure and fabric quality strengthened the brand’s reputation for excellence.

Customer Satisfaction