![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

Model:

![]() NET Weight:

NET Weight:

![]() Diameter:

30’’

Diameter:

30’’

![]() Gauge:

8G-28G

Gauge:

8G-28G

![]() Feeder:

90F

Feeder:

90F

![]() Certification:

CE, ISO

Certification:

CE, ISO

![]() Applicable Yarn Material:

Cotton, Chemical fiber, blended yarn, silk and wool etc.

Applicable Yarn Material:

Cotton, Chemical fiber, blended yarn, silk and wool etc.

![]() RPM:

20-30RPM

RPM:

20-30RPM

![]() Wooden Box Size:

2.7M*2.3M*2.5M

Wooden Box Size:

2.7M*2.3M*2.5M

![]() Place of Origin:

CHINA.

Place of Origin:

CHINA.

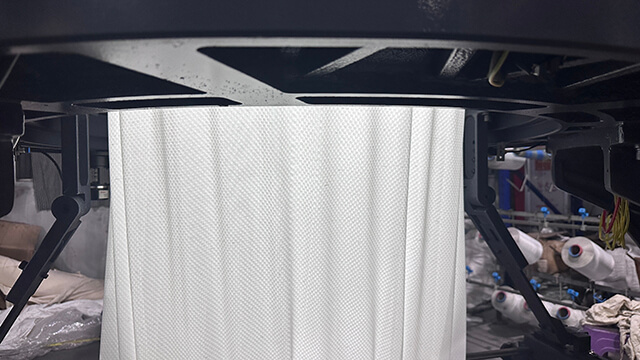

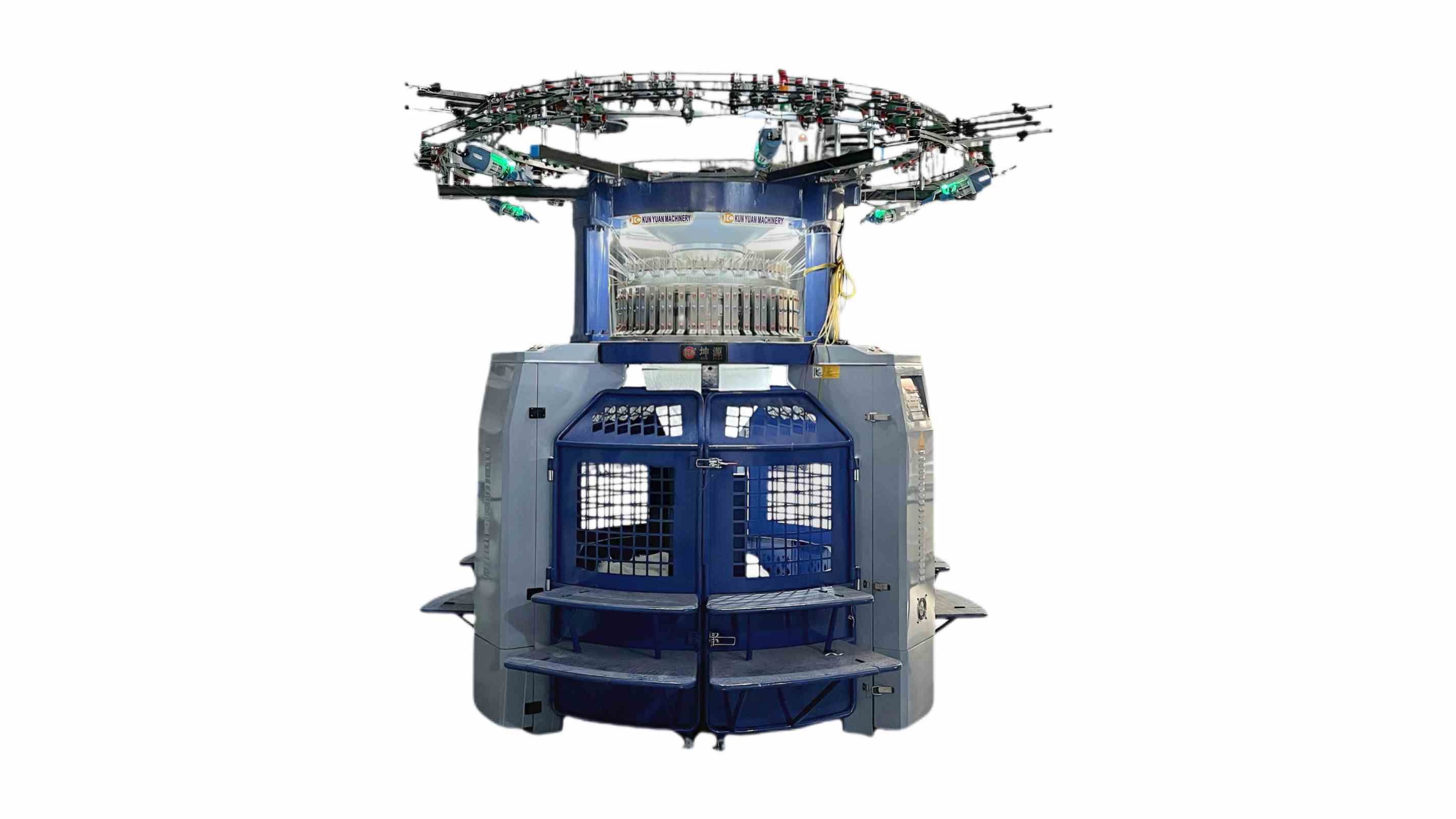

Three Thread Fleece Circular Knitting Machine is engineered for the efficient production of high-quality fleece fabrics. Designed with advanced triple-thread knitting technology and precision control systems, this machine delivers superior fabric texture, consistency, and productivity. Ideal for manufacturing fleece used in sportswear, underwear, babywear, and more, it combines versatility with robust construction to meet the needs of modern textile manufacturing.

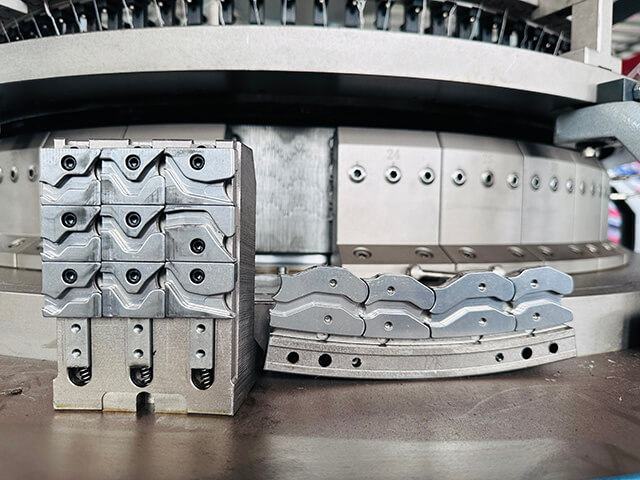

Triple Thread System

Incorporates three separate yarn feeds—tie-in yarn, ground yarn, and lay-in yarn—for optimal control of fabric thickness, warmth, and surface softness.

Circular Knitting Design

Enables seamless, continuous fabric production, enhancing strength and eliminating the need for side stitching in garments.

Variable Speed Control

Offers flexible speed settings, allowing for adjustments based on yarn type, gauge, and desired fabric properties.

Automatic Yarn Tensioning

Integrated system maintains consistent yarn tension across all feeds, ensuring even knitting and uniform fleece quality.

Four-Track Cam System

Supports diverse fabric structures and patterns, with 3 feeders per inch, maximizing fabric customization and performance.

Perfect for producing a wide range of fleece-based apparel, including:

Underwear

Sportswear

Babywear

Loungewear

Compatible with a variety of yarns: cotton, chemical fibers, blended yarns, silk, wool, and more.

| Model | Diameter | Gauge | Feeders | Application Yarn Material |

|---|---|---|---|---|

| FL | 30’’ | 8G–28G | 90F | Cotton, Chemical Fiber, Blended Yarn, Silk, Wool |

| 32’’ | 96F | |||

| 34’’ | 102F | |||

| 36’’ | 108F |

| Diameter | Gauge | RPM | Yarn Types | GSM | Width |

|---|---|---|---|---|---|

| 32’’ | 20G | 23 |

Tie-in: 75D Ground: 30s Lay-in: 12s |

265–320 g/m² | 75–83 cm |

| 34’’ | 20G | 22 | 265–320 g/m² | 81–88 cm | |

| 32’’ | 26G | — |

Tie-in: 30s Ground: 12s Lay-in: 12s |

200–290 g/m² | 75–83 cm |

| 34’’ | 26G | 24 | 240–290 g/m² | 77–87 cm |

Speed depends on yarn type, gauge, and knitting conditions. Select appropriate settings for best performance.

| Diameter | Gauge | Feeders | RPM Range |

|---|---|---|---|

| 24’’ | 14G–24G | 72F | 20–30 RPM |

| 26’’ | — | 78F | |

| 30’’ | — | 90F | |

| 34’’ | — | 102F |

| Model | Diameter | Net Weight | Gross Weight | Wooden Box Dimensions (L × W × H) |

|---|---|---|---|---|

| FL | 34’’ | 2.0 T | 2.5 T | 2.25 m × 2.23 m × 2.25 m |

Main Functions:

1. Fleece Fabric Production: The machine enables the efficient production of high-quality fleece fabrics with varying thickness, textures, and patterns.

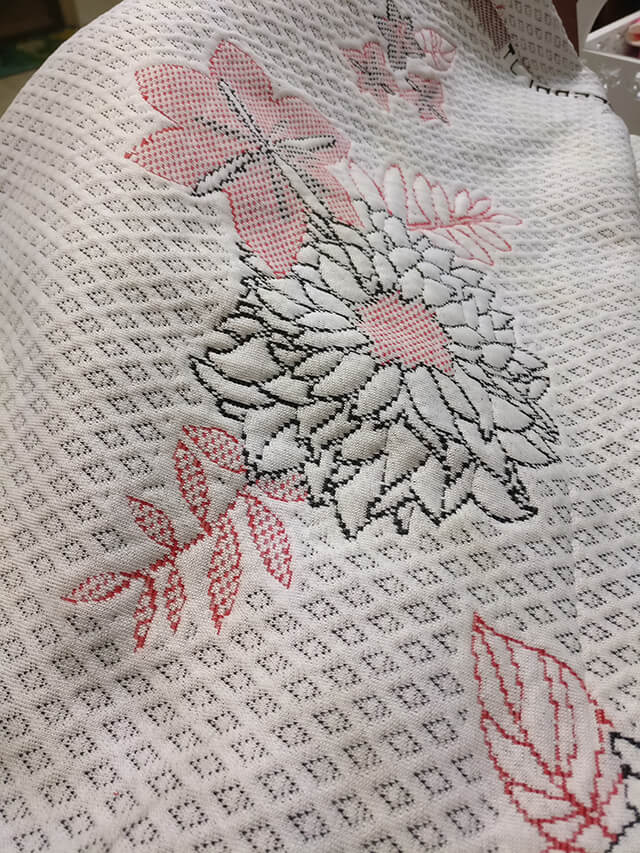

2. Fabric Customization: It allows for customization of fabric specifications, including density, pile height, and stretch, to meet specific design requirements.

3. Seamless Knitting: By utilizing its circular knitting design, the machine produces seamless fabrics, eliminating the need for additional stitching processes.

4. High-Speed Production: With its adjustable speed settings and triple thread system, the machine can achieve high productivity, optimizing production efficiency.In conclusion, the Three Thread Fleece Circular Knitting Machine is an advanced and versatile knitting solution that offers precise control, seamless fabric production, and customization options. It serves various industries and facilitates the creation of high-quality fleece fabrics with superior comfort and aesthetic appeal.

Important Considerations:

1. Proper Maintenance: Regular maintenance and cleaning are essential to ensure optimal performance and longevity of the machine. Follow the manufacturer's guidelines for maintenance procedures.

2. Operator Training: Adequate training should be provided to machine operators to familiarize them with the machine's operation, safety protocols, and troubleshooting techniques.

3. Safety Measures: Operators should follow all safety instructions and wear appropriate protective gear while working with the machine to prevent accidents and injuries.

Application Areas:

The Three Thread Fleece Circular Knitting Machine finds its application in various industries, including:

1. Textiles: It is widely used in the textile industry for producing fleece fabrics used in clothing, home textiles, and accessories.

2. Apparel Manufacturing: The machine is ideal for the production of fleece garments such as jackets, sweaters, hoodies, and blankets.

3. Upholstery: It can also be employed for manufacturing fleece upholstery fabrics used in furniture, automotive interiors, and other decorative applications.

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balances...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should strictly adhere to safety...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its advanced technology and ve...

Introduction to High Pile Jacquard Circular Knitting MachineHigh Pile Jacquard Circular Knitting Machine is a specialized machinery used for creating high pile fabrics with intricate designs. It combines the ...

The Double Jacquard Circular Knitting Machine is a highly versatile and technologically advanced knitting machine. It utilizes a double jacquard mechanism to create intricate and complex designs on knitted fa...

Its durable design ensures consistent quality and smooth operation, making it perfect for producing high-quality fleece fabrics in large quantities.2025-07-11