Improved Efficiency. Versatility in Design. Enhanced Comfort and Fit. Cost Efficiency. Increased Durability. Reduced Environmental Impact. Greater Customization. Improved Profitability. Conclusion....

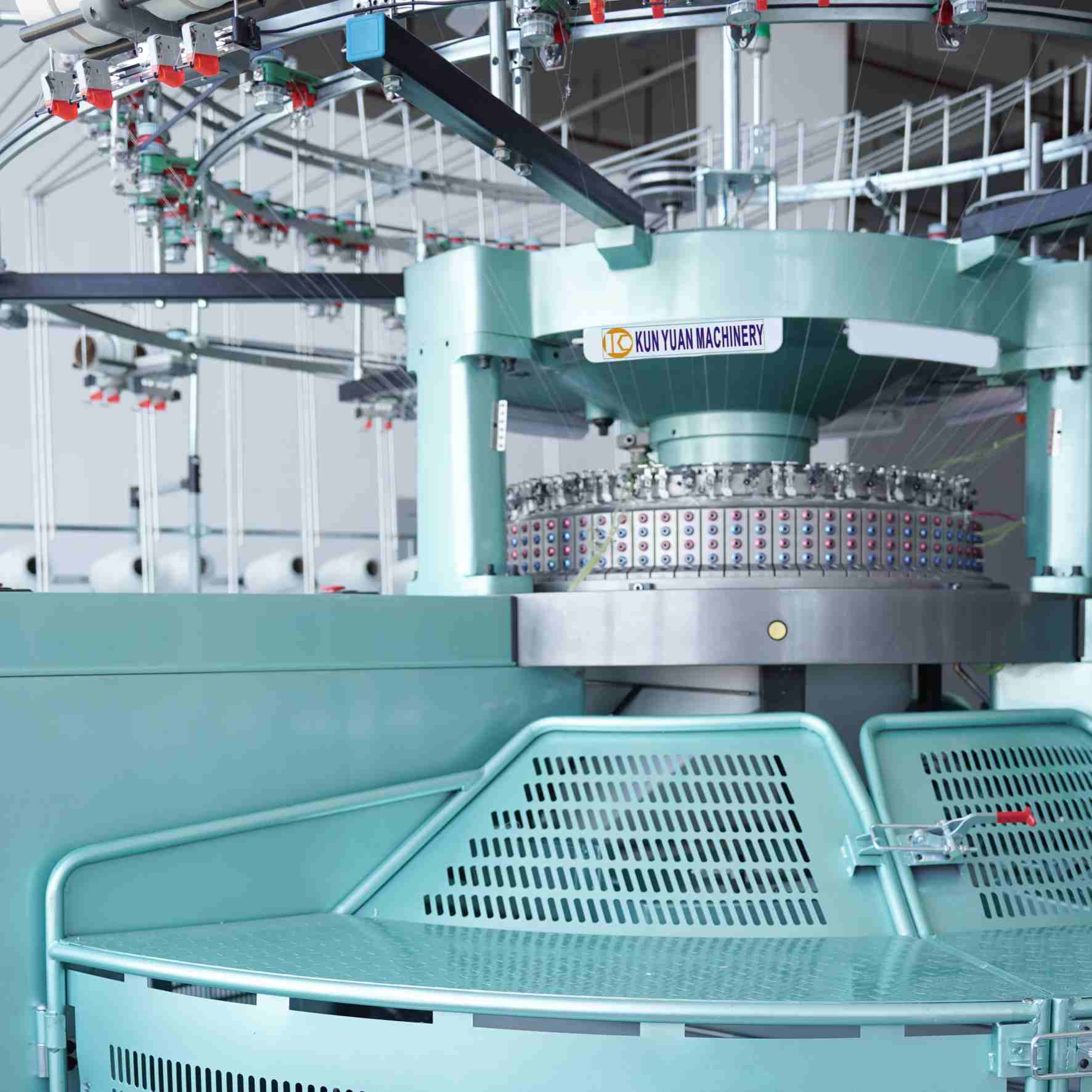

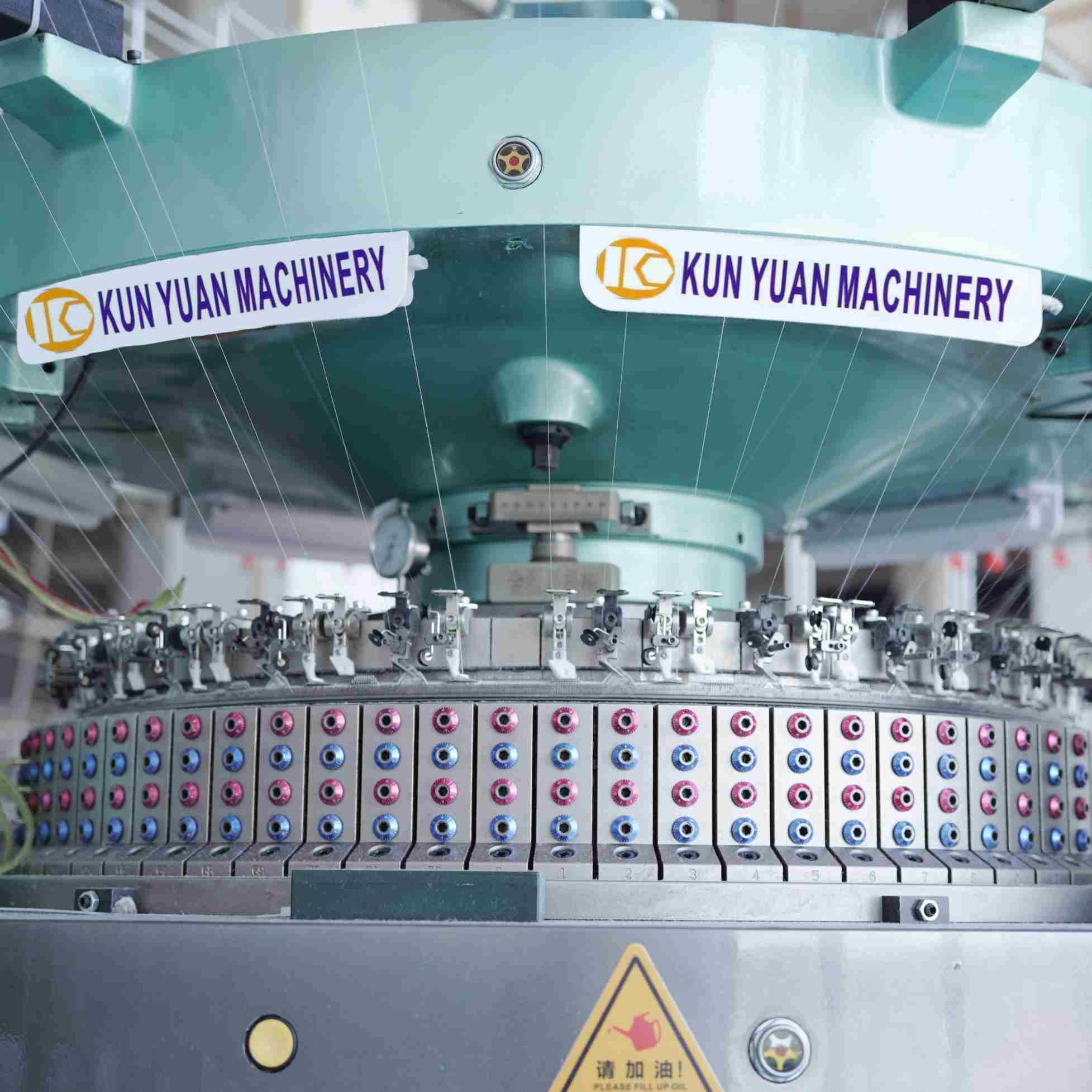

Advantages of Body Size Circular Knitting Machine. High Production Efficiency. Versatility in Fabric Production. Reduced Material Wastage. Quality Control and Consistency. Advanced Technological Features. Energy Efficiency and Sustainability. Production Process of Body Size Circular Knitting Machine. Conclusion....

Early Manual Circular Knitting Machines. Introduction of Semi-Automatic Machines. Transition to Fully Automatic Machines. Incorporation of Computerized Systems. Advancements in Body Size and Speed. Integration of Sustainable Practices. Impact on Textile Industry. Conclusion....

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

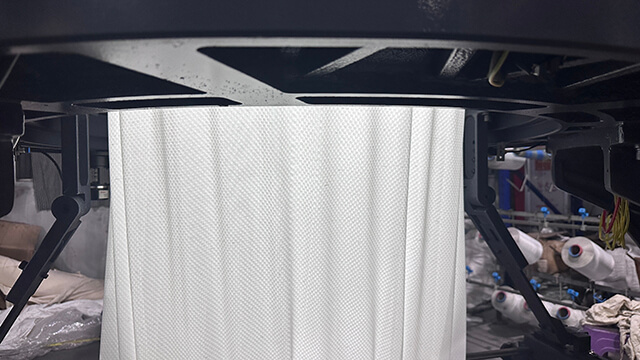

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

1. Proper maintenance: Regular maintenance is essential to ensure the smooth operation of the machine. Follow the manufacturer's instructions for cleaning, lubrication, and other mainte...

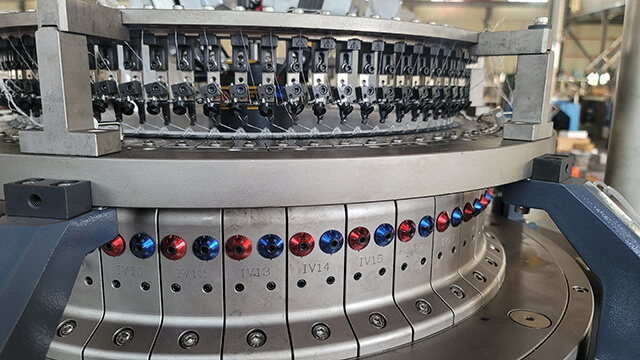

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for p...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...