1. Unpacking. 2. Assembling the Frame. 3. Attaching the Knitting Loom. 4. Mounting the Yarn Tensioner. 5. Installing the Needle Bed. 6. Connecting Power and Controls. 7. Adding Accessories. 8. Final Checks. Conclusion....

1. Consider the Size. 2. Check the Gauge. 3. Evaluate the Material. 4. Look for Versatility. 5. Consider the Price. 6. Read Reviews. 7. Test the Machine. 8. Seek Recommendations. Conclusion....

1. Seamless Garments. 2. Accessories. 3. Home Decor. 4. Toys and Amigurumi. 5. Baby Items. 6. Therapy and Rehabilitation. 7. Educational Tool. 8. Small Business Endeavors. Conclusion....

Step 1: Gather Your Materials. Step 2: Attach the Pegs. Step 3: Cast On. Step 4: Create the Foundation Row. Step 5: Knit the Rows. Step 6: Continue Knitting. Step 7: Bind Off. Step 8: Finishing Touches. Conclusion....

Introduction. Early Developments. Mechanization and Automation. Introduction of Synthetic Fibers. Computerization and Digitalization. Advancements in Circular Knitting Technology. Sustainability and Efficiency. Conclusion....

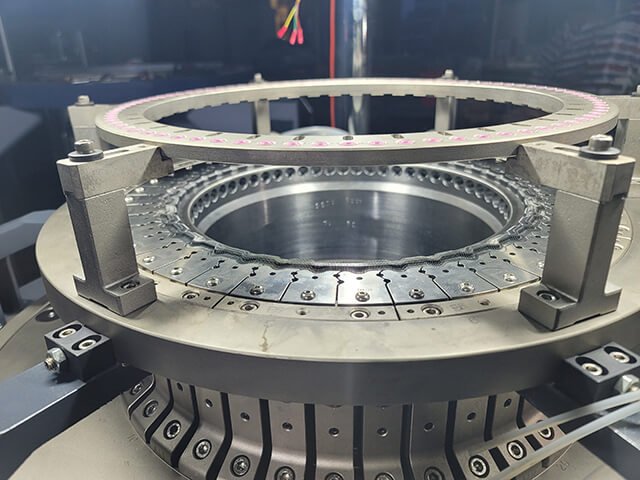

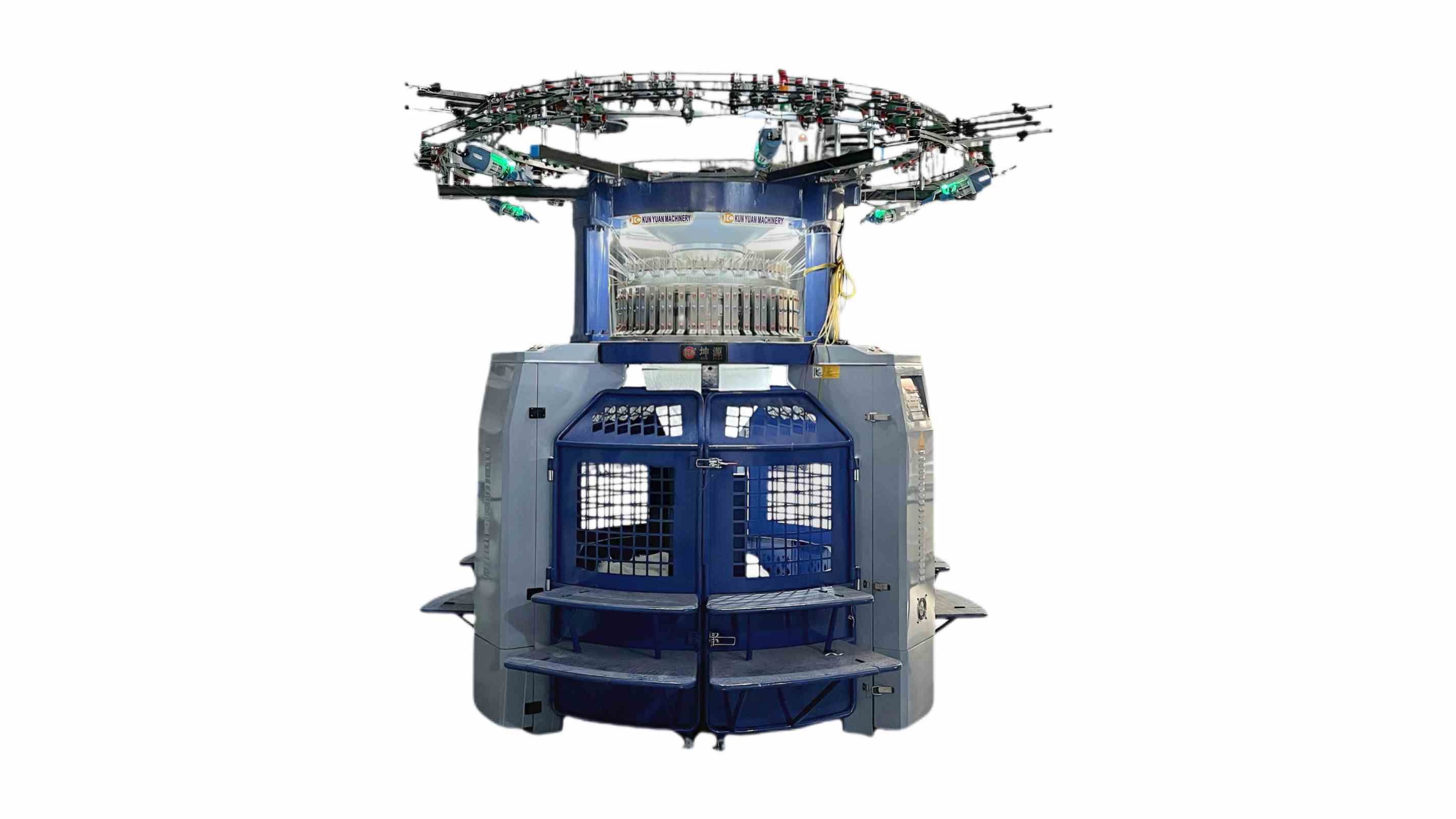

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...