1. Assess Your Production Needs. 2. Research Different Types of Weft Knitting Machines. 3. Consider Machine Features and Specifications. 4. Assess Machine Durability and Reliability. 5. Evaluate After-Sales Support and Service. 6. Consider Cost and Return on Investment. 7. Seek Expert Advice and References. 8. Request Machine De...

1. Determine Your Production Requirements. 2. Evaluate Machine Features. 3. Consider Machine Size and Configuration. 4. Quality and Reliability. 5. Cost and Return on Investment. 6. Technical Support and Training. 7. Consider Future Expansion. 8. Seek Expert Advice. Conclusion....

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

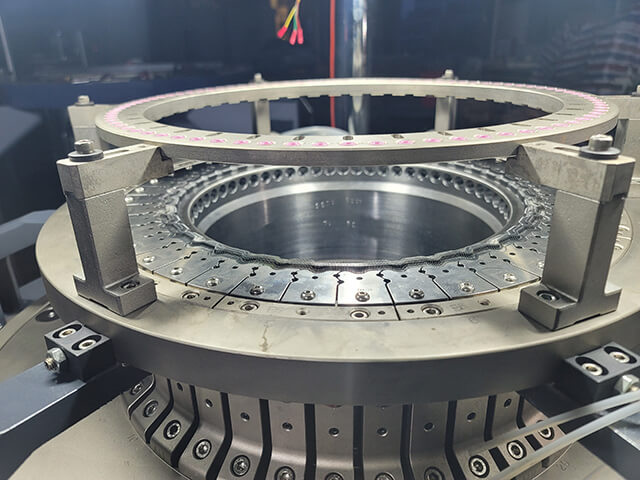

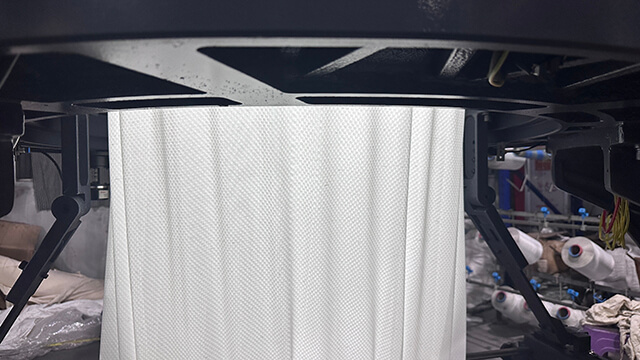

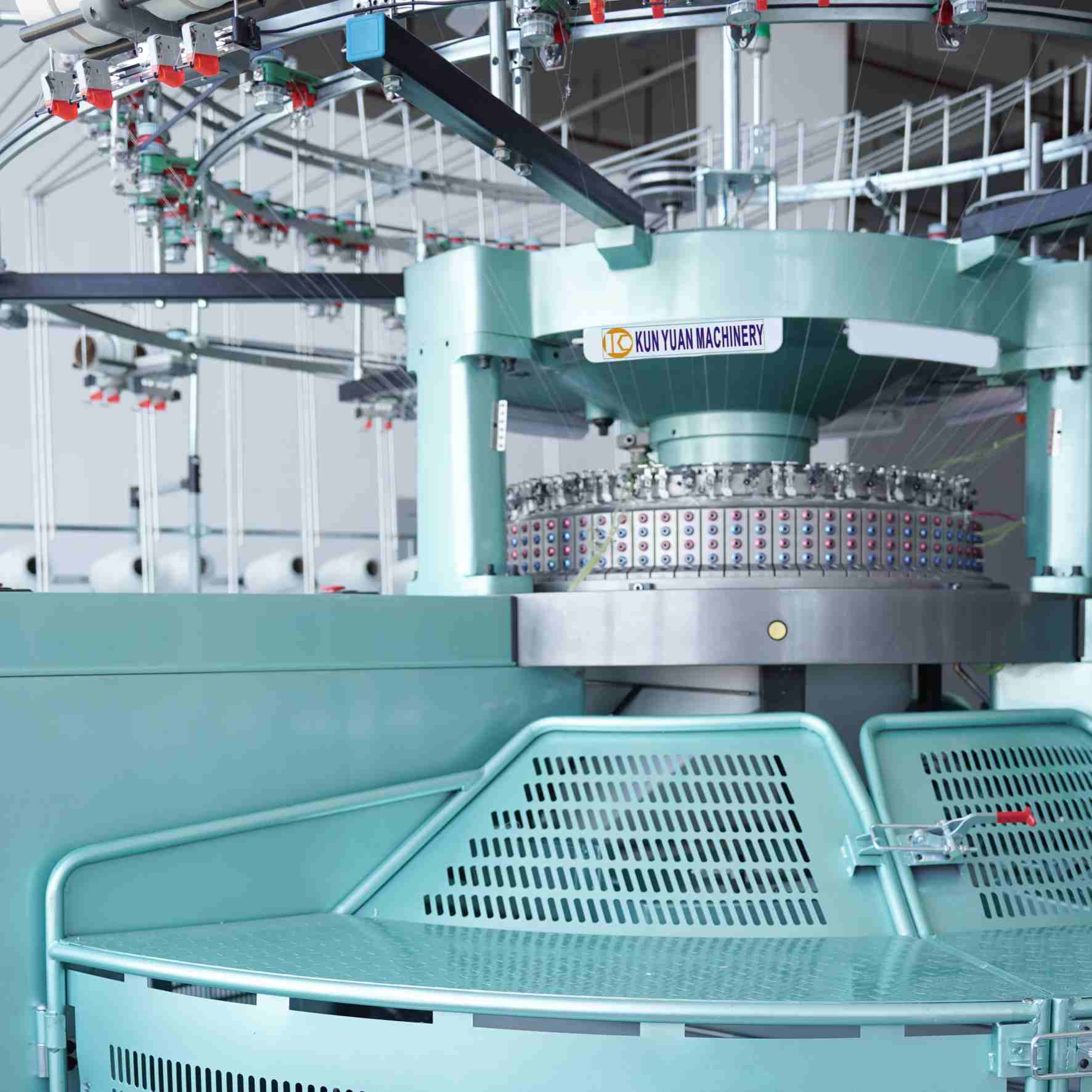

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elasti...

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...