Installation Guide for Pailung Circular Knitting Machine. 1. Unpacking and Inspection. 2. Machine Placement. 3. Power Connection. 4. Machine Assembly. 5. Lubrication. 6. Thread Installation. 7. Machine Calibration. 8. Test Run and Troubleshooting. Summary....

1. Determine Your Requirements. 2. Research Pailung Circular Knitting Machines. 3. Consider Your Budget. 4. Evaluate After-Sales Support. 5. Seek Expert Advice. 6. Compare Prices and Warranty. 7. Purchase from an Authorized Dealer. 8. Make Your Purchase. Conclusion....

1. Apparel Industry. 2. Sportswear and Activewear. 3. Home Textiles. 4. Automotive Industry. 5. Medical Textiles. 6. Technical Textiles. 7. Footwear Manufacturing. 8. Accessories and Lingerie. Conclusion....

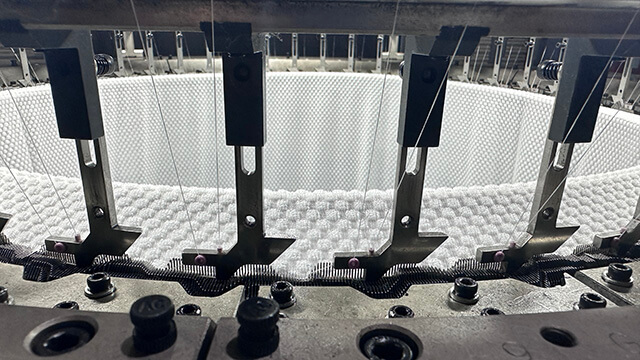

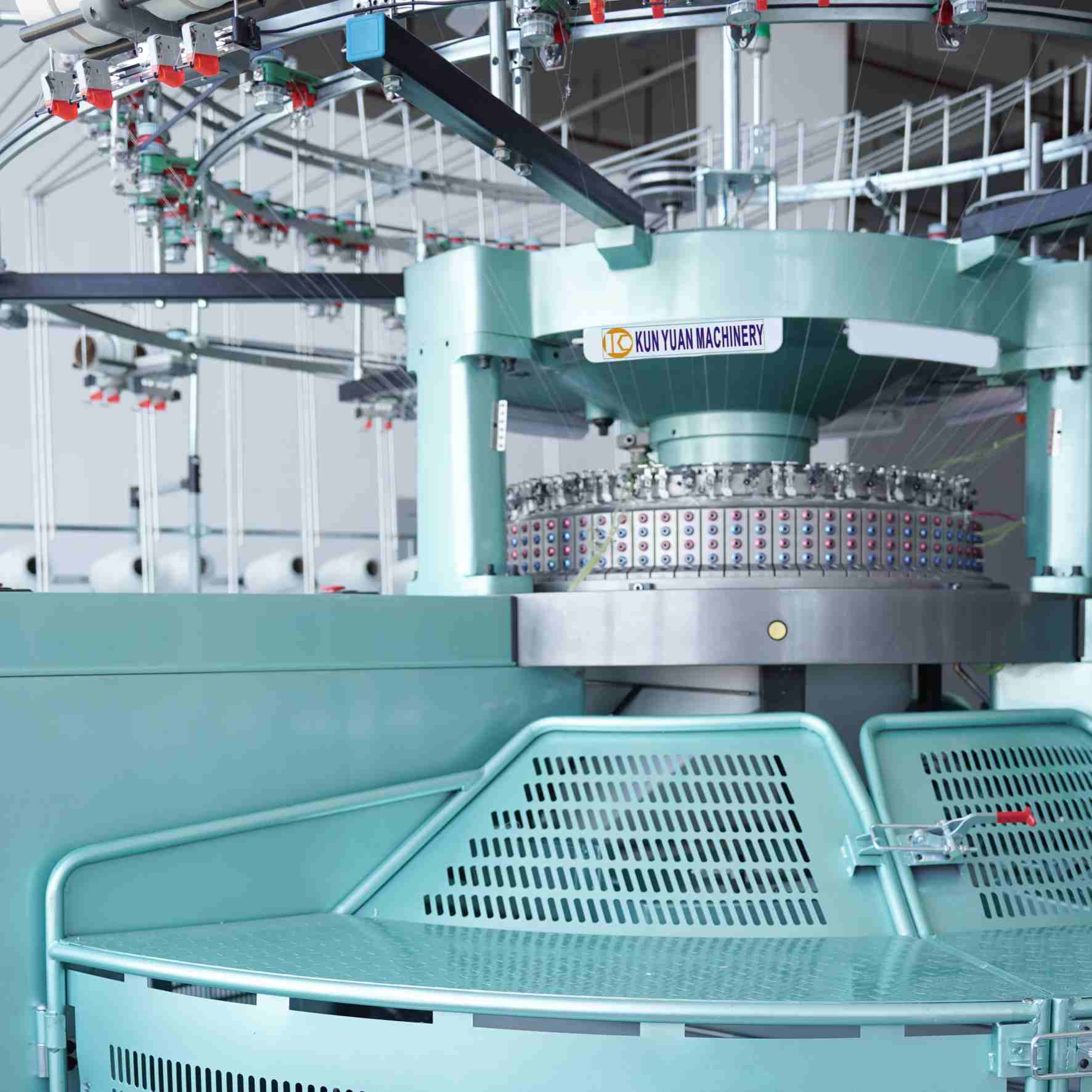

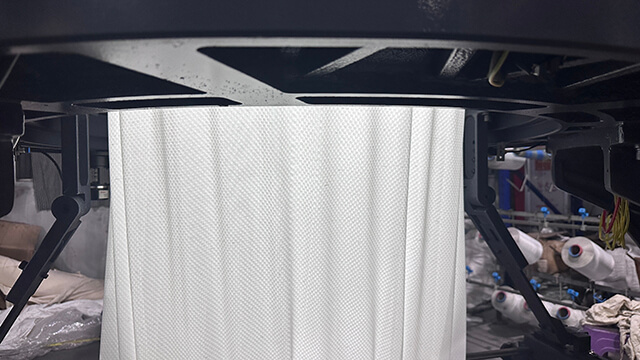

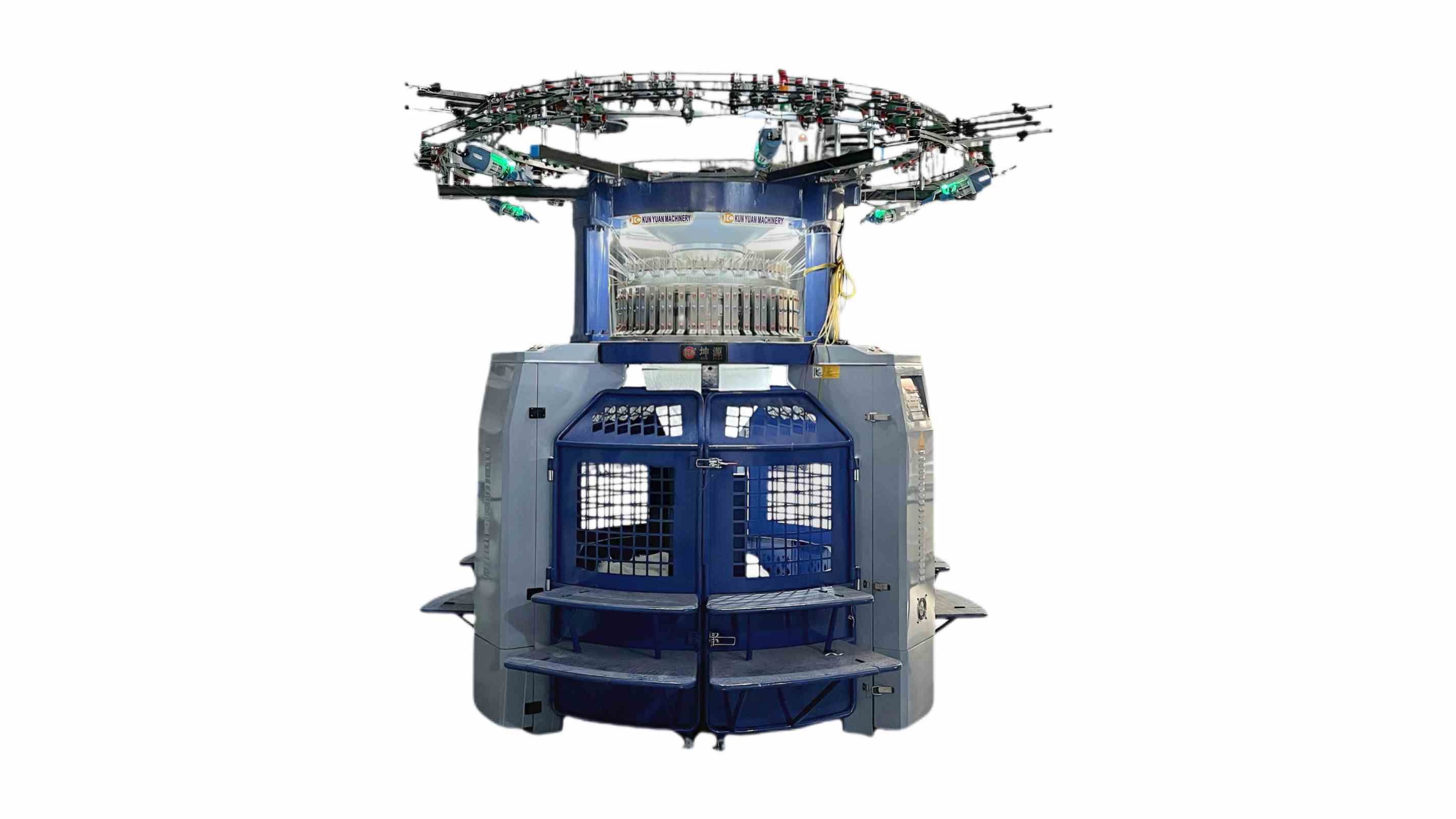

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for p...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...