Introduction. 1. Enhanced Design Flexibility. 2. Efficient Production Process. 3. Seamless Comfort and Fit. 4. Customization and Personalization. 5. Sustainable Production. 6. Innovation in Shape and Structure. 7. Integration with Technology. 8. Expanding Market Opportunities. Conclusion....

The Origins of Circular Knitting. Early Circular Knitting Machines. The Introduction of Automated Circular Knitting Machines. Advancements in Technology. Specialized Circular Knitting Machines for Hats. Incorporation of Sustainable Practices. Integration of Smart Features. Future Prospects and Innovations. In Conclusion....

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

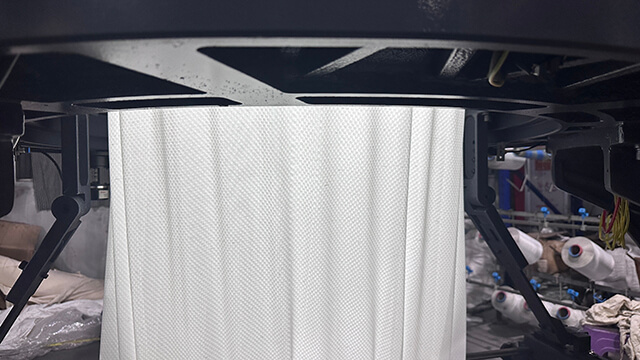

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...