1. Unboxing and Inspection. 2. Assembly. 3. Yarn Installation. 4. Setting Up Needle Beds. 5. Power Connection. 6. Machine Calibration. 7. Test Run. 8. Start Knitting!. Conclusion....

Introduction. 1. Determine Your Knitting Goals. 2. Consider Machine Type. 3. Evaluate Knitting Bed Size. 4. Check Needle Compatibility. 5. Research Machine Features. 6. Consider Portability. 7. Read Reviews and Seek Recommendations. 8. Set a Budget. Conclusion....

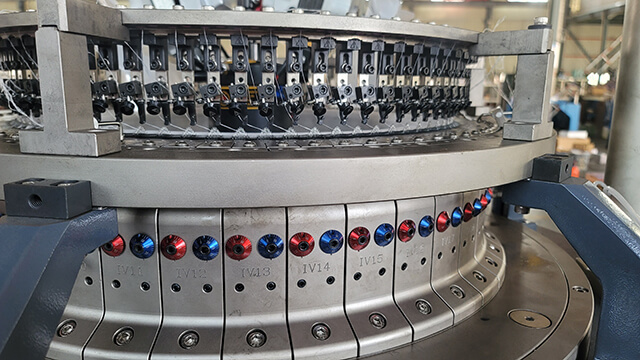

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and effi...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...