Introduction. 1. Determine Your Production Requirements. 2. Consider Machine Specifications. 3. Assess Machine Brands and Suppliers. 4. Evaluate Machine Features. 5. Consider Ease of Use. 6. Evaluate Cost and Return on Investment. 7. Seek Expert Advice. Conclusion....

Introduction. Advantages of Automatic Circular Knitting Machine. Production Process of Automatic Circular Knitting Machine. Conclusion....

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

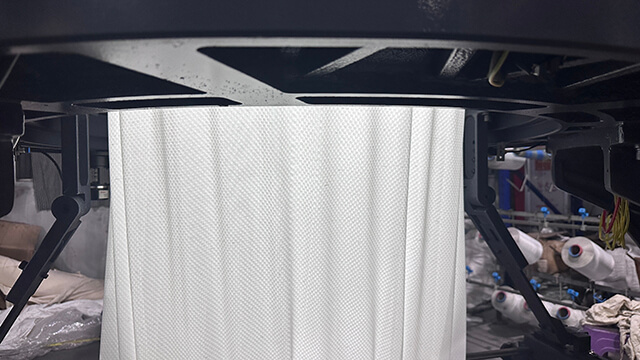

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elasti...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...