1. Determine Your Needs. 2. Research Brands and Models. 3. Consider Machine Features. 4. Assess Durability and Reliability. 5. Evaluate Price and Value. 6. Test the Machine. 7. Compare Warranty and Support. 8. Seek Recommendations. Conclusion....

Early Origins. Mechanization and Industrialization. Computerization and Automation. Innovations in Materials. Sustainability and Environmental Considerations. Integration of Smart Features. Future Prospects and Advancements. Conclusion....

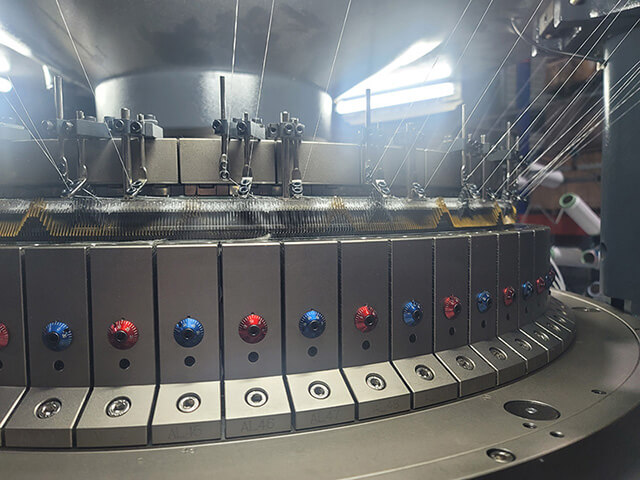

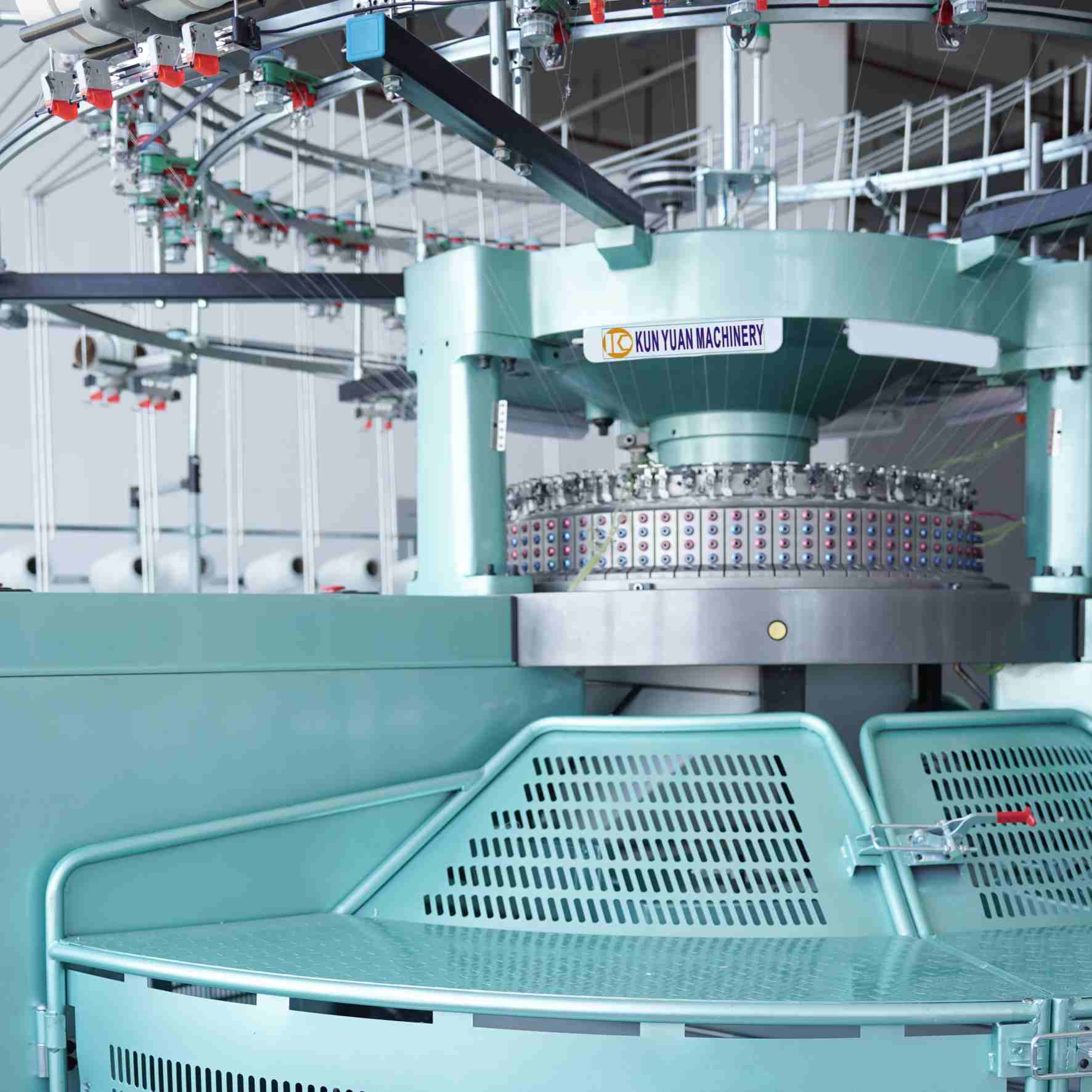

Advantages of High Pile Knitting Machine. 2. Efficiency and Speed. 3. Enhanced Texture and Appearance. 4. Customization and Innovation. 5. Environmental Sustainability. 6. Consistency and Quality. 7. Cost-Effectiveness. 8. Automation and Control. Production Process of High Pile Knitting Machine. Yarn Feeding. Knitting. Pile Form...

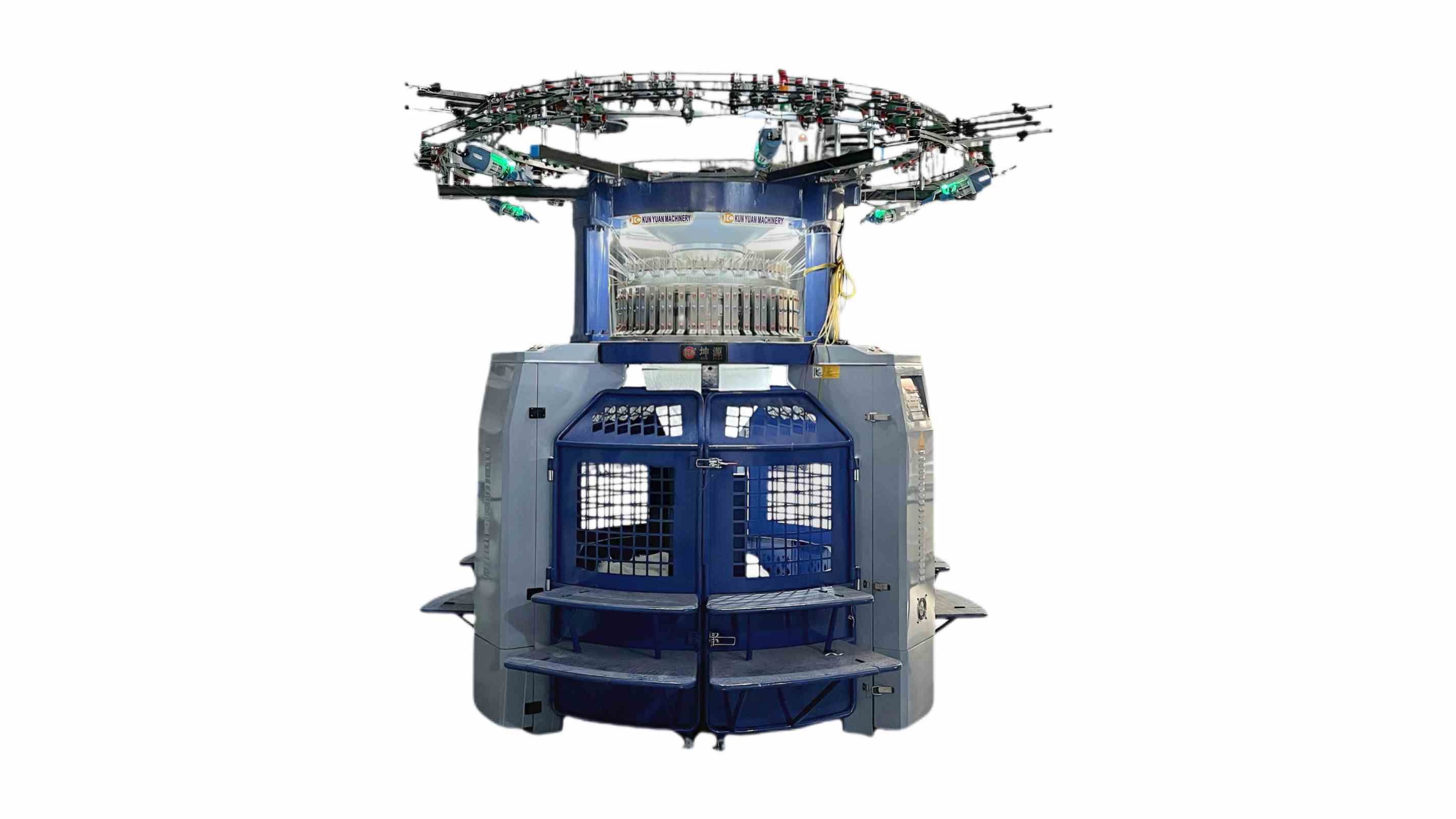

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and effi...

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...