1. The Birth of Circular Knitting Machines. 2. Technological Advancements: Cast-Iron to High-Strength Alloys. 3. On-the-Fly Pattern Changes. 4. Automation and Digitization. 5. Versatility: From T-Shirts to Technical Textiles. 6. Energy Efficiency and Sustainability. 7. Integration of Industry 4.0 Technologies. 8. Future Prospect...

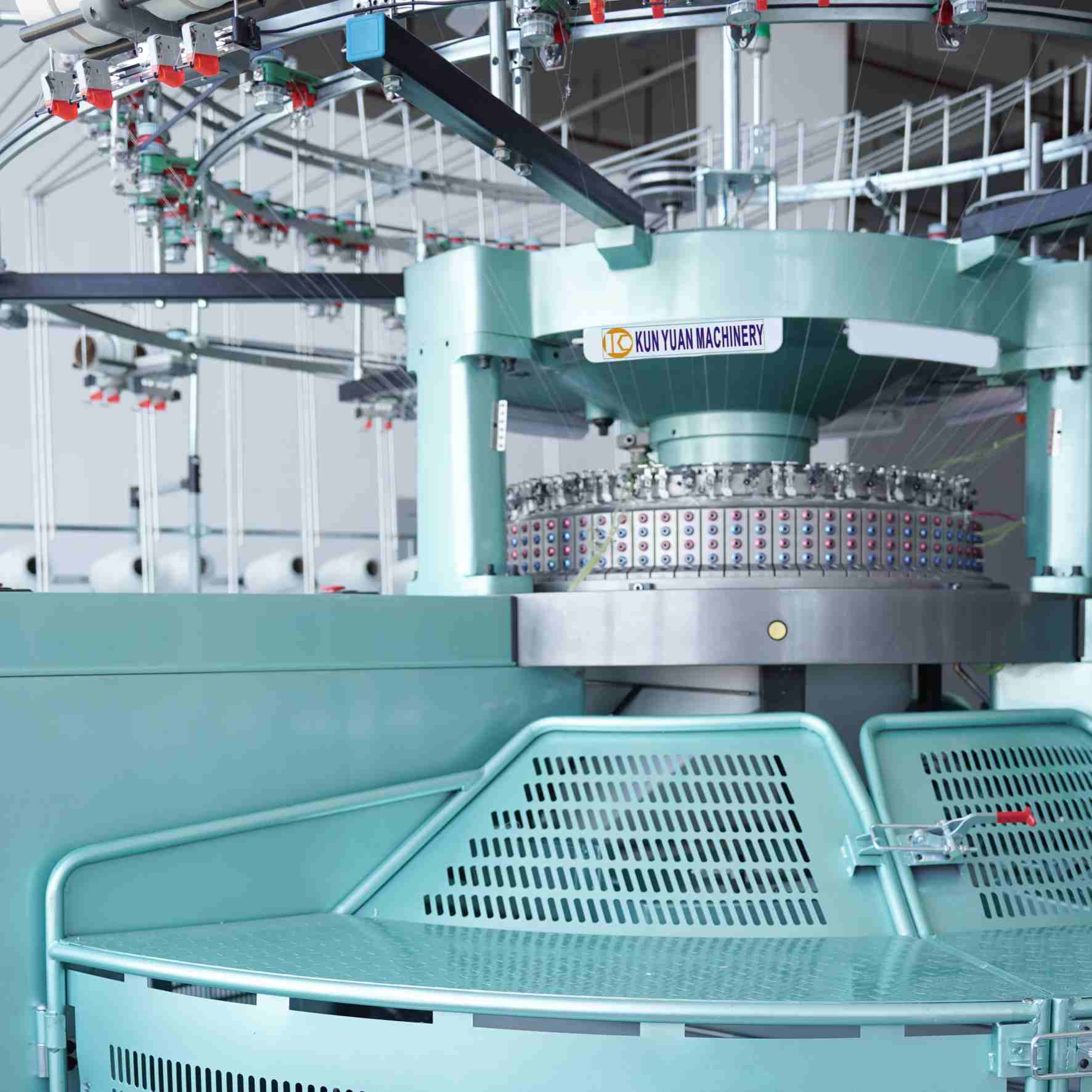

Advanced Technology. Versatile Production Capabilities. Efficient Output Efficiency. Energy and Resource Savings. Intuitive Operation and Maintenance. Quality Control and Consistency. Adaptability to Different Yarns and Fibers. Integration with Industry 4.0....

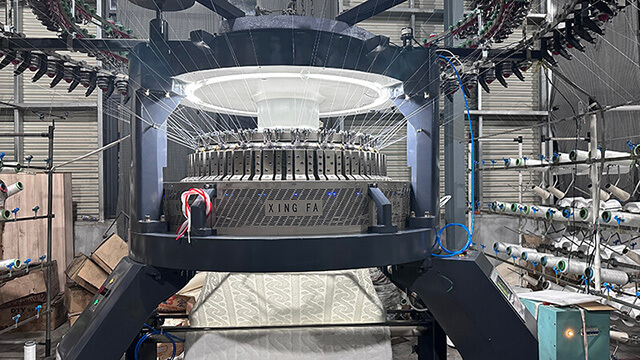

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...