Introduction. 1. Unpacking the Machine. 2. Placement and Leveling. 3. Power Supply. 4. Installing Needles and Yarn Feeders. 5. Lubrication. 6. Testing and Calibration. 7. Safety Measures. Conclusion....

1. Production of Basic Knitted Fabrics. 2. Seamless Garment Production. 3. Elastic and Stretch Fabrics. 4. Textured and Patterned Fabrics. 5. Jacquard and Intarsia Knitting. 6. Sample and Prototyping. 7. Recycling and Upcycling Projects. 8. Knitting Education and Training. Conclusion:....

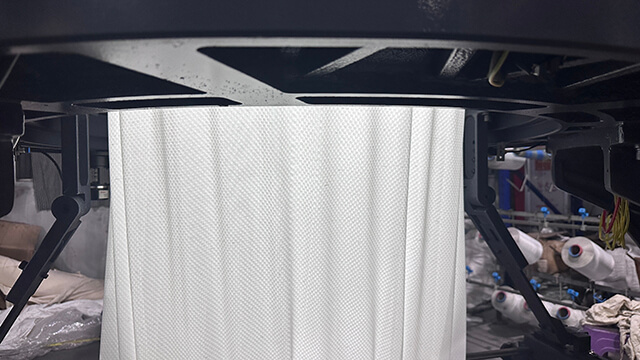

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

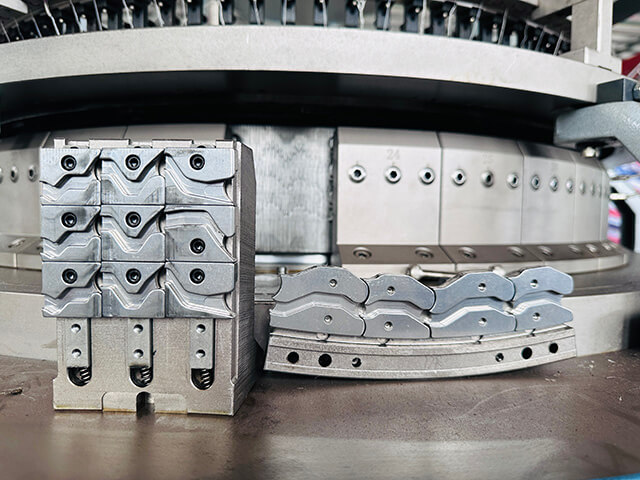

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and effi...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...