1. Consider the Knitting Speed. 2. Evaluate the Number of Knitting Heads. 3. Check the Gauge Options. 4. Review the Software Capabilities. 5. Assess the Yarn Feeding System. 6. Consider Maintenance and Support. 7. Compare Price and Value. 8. Read Customer Reviews. Conclusion....

1. Knitting Principle. 2. Yarn Feeding Mechanism. 3. Jacquard System. 4. Pattern Design Software. 5. Tension Control. 6. Fabric Inspection System. 7. Production Speed and Efficiency. 8. Applications. Conclusion....

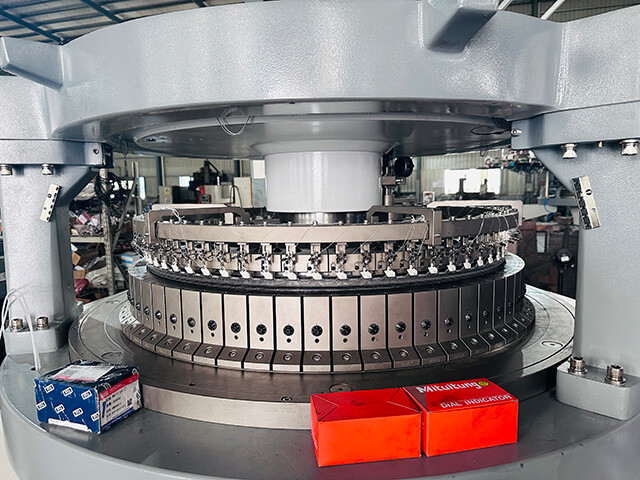

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitti...

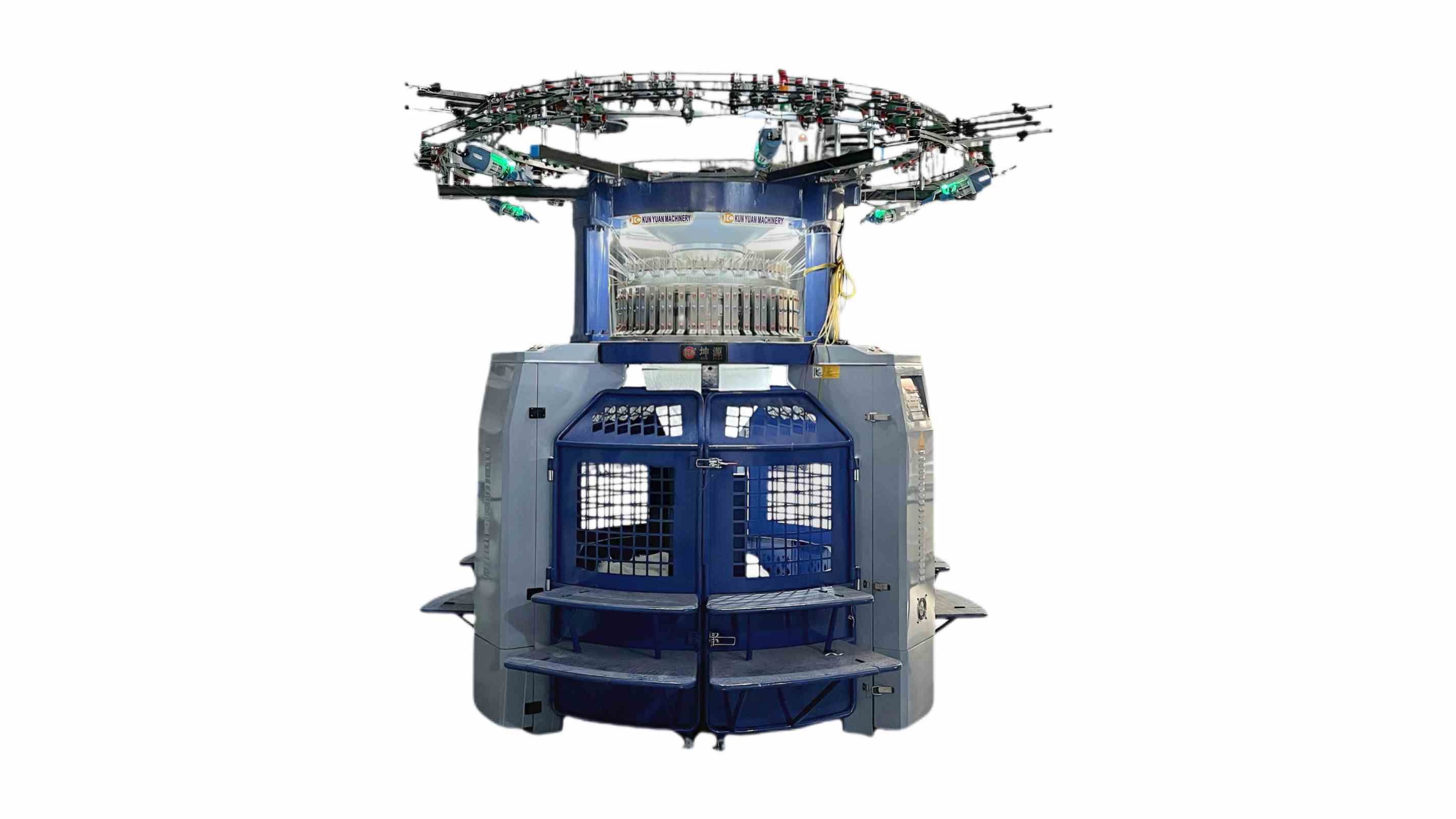

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...