Introduction. 1. Consider Your Project Requirements. 2. Research Different Brands and Models. 3. Evaluate Machine Features. 4. Consider Machine Size and Portability. 5. Examine Machine Durability. 6. Compare Prices and Warranty. 7. Seek Professional Advice. 8. Test the Machine Before Purchase. Conclusion....

1. Introduction to Circular Pile Knitting Machines. 2. Increased Efficiency. 3. Versatility in Fabric Design. 4. Enhanced Durability. 5. Reduced Waste. 6. Environmental Sustainability. 7. Advances in Technology. 8. Conclusion. Summary....

1. Understanding the Machine. 2. Selecting the Right Yarn. 3. Preparing the Yarn. 4. Tension Control. 5. Proper Needle Selection. 6. Maintaining the Machine. 7. Planning and Organization. 8. Practice and Patience. Conclusion....

Early Innovations. Mechanical Advancements. Technological Breakthroughs. Material Compatibility. Environmental Considerations. Global Impact. Adaptation to Digitalization. Future Prospects. Conclusion....

Advantages of Circular Pile Knitting Machine. 2. Versatile Fabric Options. 3. Superior Fabric Quality. 4. Reduced Waste and Material Costs. 5. Customization Capabilities. 6. Energy Efficiency. Production Process of Circular Pile Knitting Machine. 8. Loop Formation and Pile Fabric Creation. Conclusion....

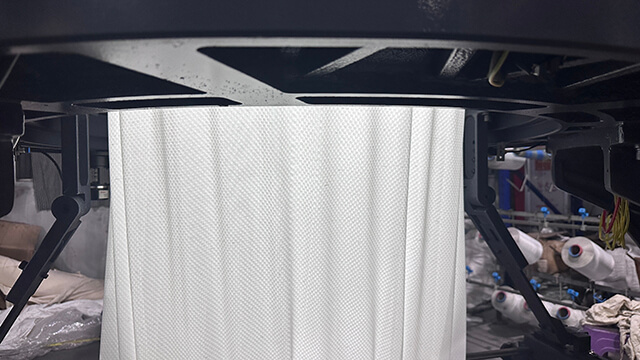

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

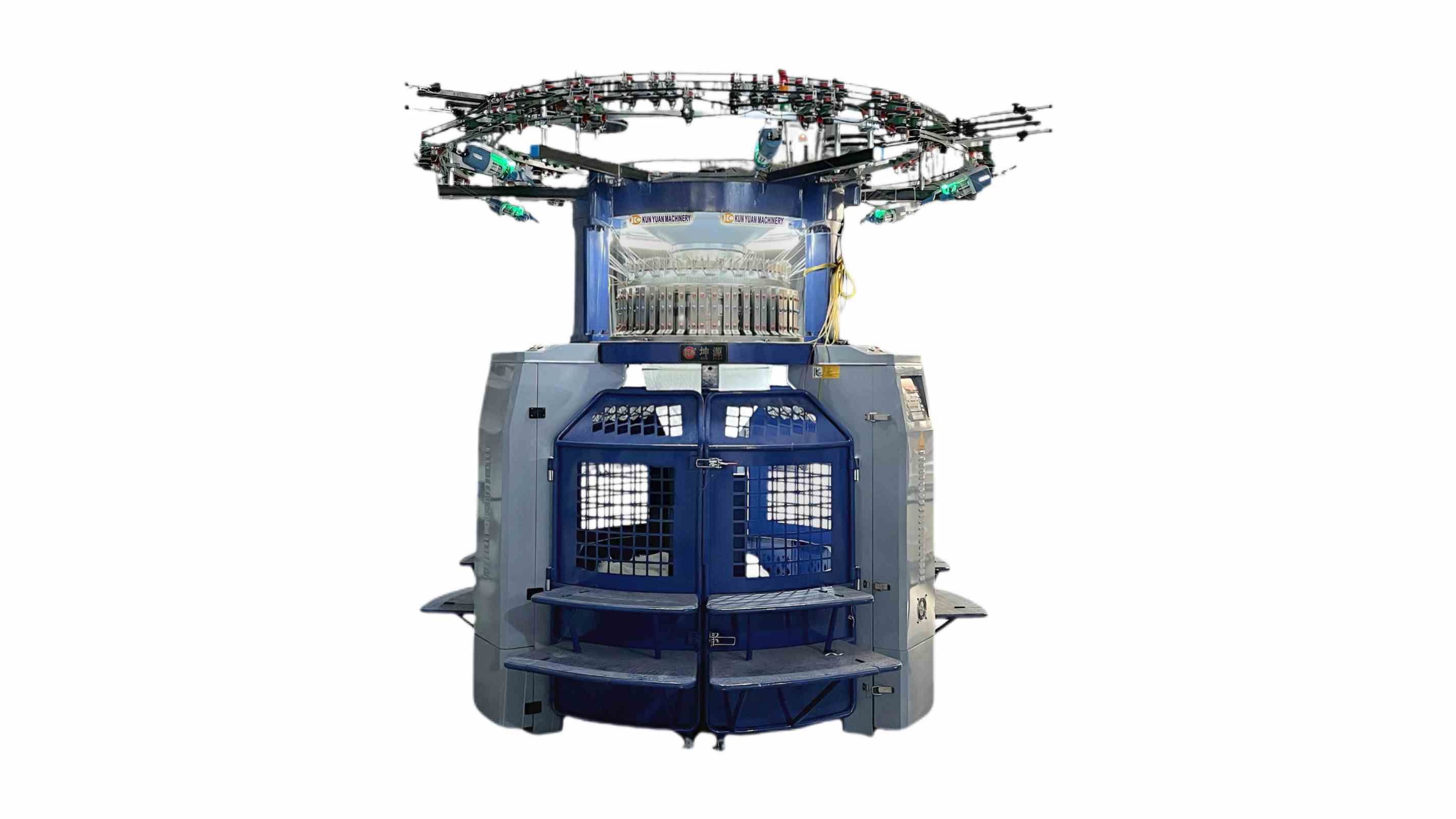

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

This machine is designed for high-efficiency production of double-sided knit fabrics. With a 24-gauge needle system, it offers fine, high-density knitting suitable for smooth and elasti...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for p...