1. Yarn Feeding. 2. Stitch Formation. 3. Pattern Programming. 4. Size and Shape Customization. 5. Seamless Construction. 6. Quality Control. 7. Speed and Efficiency. 8. Data Storage and Analysis. Conclusion....

Introduction. 1. Define Your Requirements. 2. Research Different Brands and Models. 3. Consider Machine Features. 4. Assess Production Capacity. 5. Examine Machine Durability. 6. Consider Cost and Return on Investment. 7. Seek Recommendations and Testimonials. 8. Request Machine Demonstration. Conclusion....

Early Manual Knitting Techniques. Invention of the First Automatic Knitting Machine. Integration of Electronic Controls. Introduction of Computerized Knitting Machines. Advancements in Material Handling and Yarn Control. Incorporation of Seamless Knitting Technology. Transition to Industry 4.0 and Smart Manufacturing. Conclusion...

1. Fashion Industry. 2. Sports Apparel. 3. Uniform Manufacturing. 4. Children's Apparel. 5. Luxury Knitwear. 6. Eco-Friendly Production. 7. Small-Scale Production. 8. Custom Knitwear. Conclusion....

1. Regular Maintenance: Proper maintenance and cleaning of the machine are essential to ensure optimal performance and prolong its lifespan. 2. Safety Measures: Operators should st...

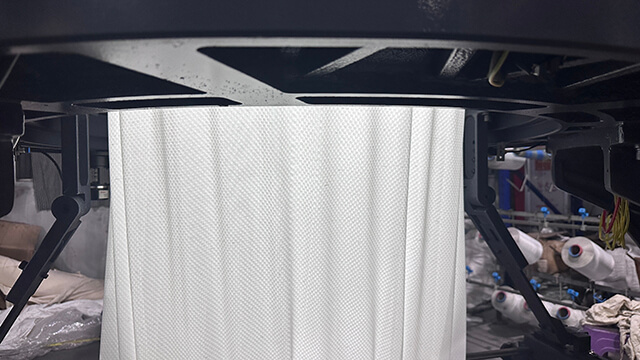

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...