1. Machine Type. 2. Needle Count. 3. Machine Size. 4. Durability and Maintenance. 5. Speed and Production Capacity. 6. User-Friendliness and Automation. 7. Power Consumption. 8. Price and Warranty. Conclusion....

1. The Basics of Motorized Knitting Machines. 2. Needle Selection and Tension. 3. Yarn Feeding and Control. 4. Stitch Formation and Transfer. 5. Pattern Programming and Jacquard Knitting. 6. Speed and Productivity. 7. Quality Control and Troubleshooting. 8. Advancements and Future Possibilities. Conclusion....

1. Seamless Knitting. 2. Elasticity Control. 3. Size and Shape Customization. 4. Multi-color Knitting. 5. Fabric Selection. 6. Production Speed. 7. Quality Control. 8. Energy Efficiency. Conclusion....

1. Electronic Jacquard System. 2. Yarn Feeding Mechanism. 3. Automatic Color Changing. 4. Multiple Knitting Heads. 5. Automated Lubrication System. 6. Digital Control Panel. 7. Automatic Fault Detection. 8. Energy Efficiency. Conclusion....

1. Introduction. 2. Increased Efficiency. 3. Versatility in Design. 4. Enhanced Control and Precision. 5. Improved Ergonomics. 6. Cost-Effectiveness. 7. Sustainable Production. 8. Conclusion. Conclusion....

Advantage 1: Versatility. Advantage 2: High Productivity. Advantage 3: Quality Fabric Output. Advantage 4: Cost-Effectiveness. Production Process Overview. Step 1: Yarn Feeding. Step 2: Knitting Action. Step 3: Fabric Collection. Step 4: Quality Inspection....

Early Manual Circular Knitting Machines. Introduction of Semi-Automatic Machines. Transition to Fully Automatic Machines. Incorporation of Computerized Systems. Advancements in Body Size and Speed. Integration of Sustainable Practices. Impact on Textile Industry. Conclusion....

Introduction. Early Developments. Mechanization and Automation. Introduction of Synthetic Fibers. Computerization and Digitalization. Advancements in Circular Knitting Technology. Sustainability and Efficiency. Conclusion....

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

The High Pile Jacquard Circular Knitting Machine is a state-of-the-art textile machinery designed to produce high-quality jacquard fabrics with a high pile finish. It is equipped with a...

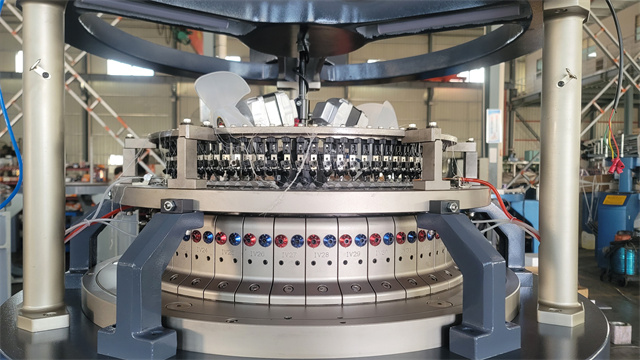

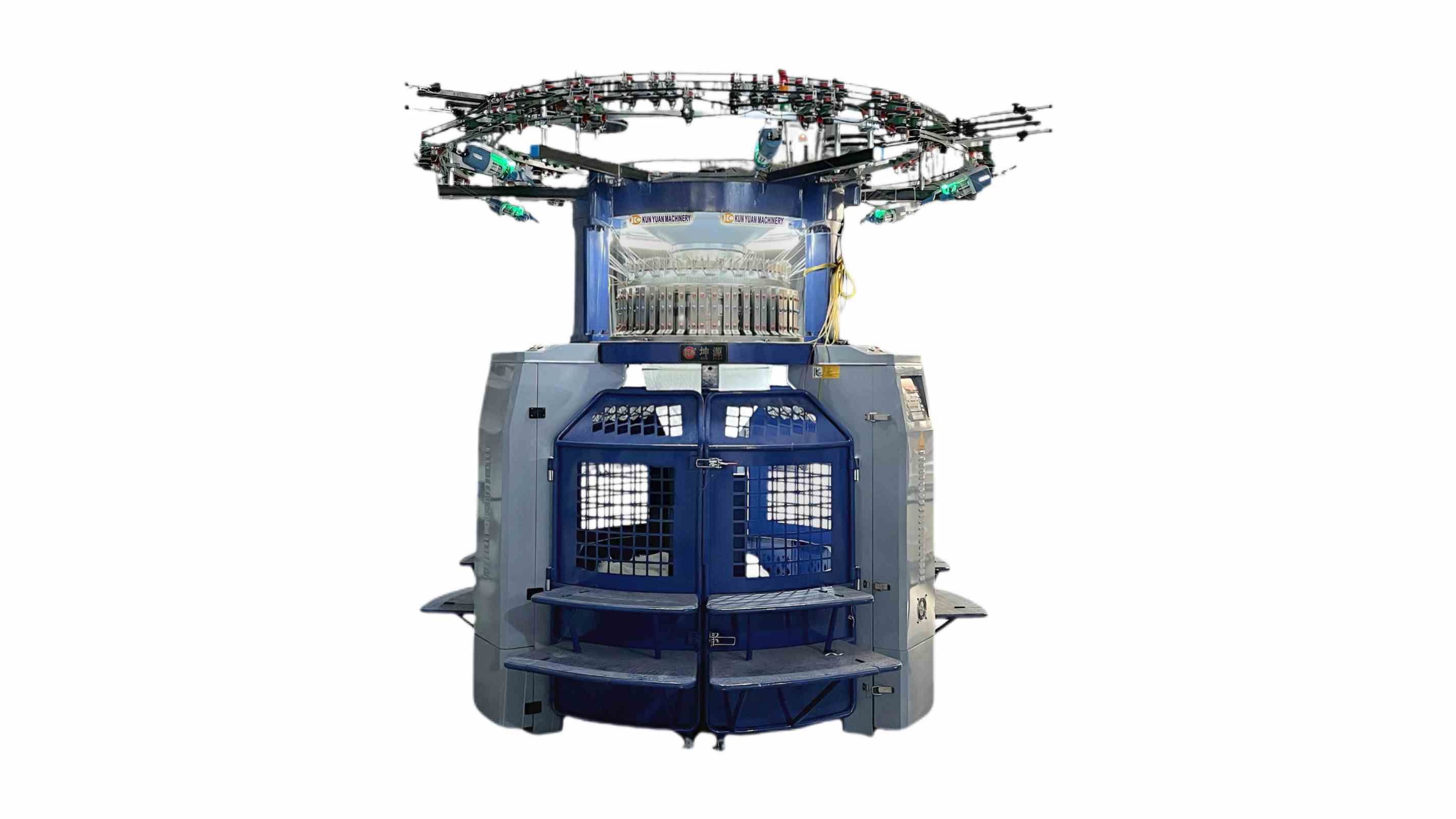

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitti...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...