The Early Origins. Mechanization and Automation. Technological Innovations. Enhanced Versatility. Efficiency and Sustainability. Digital Integration. Quality and Consistency. The Future Outlook....

Early Developments. Introduction of Circular Knitting Machines. Integration of Jacquard Technology. Advancements in Automation. Innovations in Fabric Quality. Versatility and Product Diversification. Sustainability and Eco-Friendly Solutions. Future Outlook and Conclusion....

Early Manual Designs. Introduction of Automation. Adoption of Electronic Controls. Integration of Computer Technology. Enhancements in Material Handling. Focus on Sustainable Practices. Advancements in Quality Control. Conclusion....

Early Development. Mechanical Innovations. Technological Integration. Material Adaptability. Sustainability Initiatives. Automation and Industry 4.0. Global Impact. Conclusion....

The Origins of Circular Knitting. Early Circular Knitting Machines. The Introduction of Automated Circular Knitting Machines. Advancements in Technology. Specialized Circular Knitting Machines for Hats. Incorporation of Sustainable Practices. Integration of Smart Features. Future Prospects and Innovations. In Conclusion....

1. Cleaning the Machine. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Check the Belts and Pulleys. 6. Regular Calibration. 7. Electrical Safety. 8. Record Keeping. Conclusion....

Introduction. 1. Understanding the Machine. 2. Preparing the Site. 3. Unboxing and Assembly. 4. Electrical and Mechanical Connections. 5. Calibrating and Testing. 6. Training and Familiarization. 7. Integration with Production Workflow. 8. Maintenance and Support. Conclusion....

1. Regular Cleaning. 2. Lubrication. 3. Needle Maintenance. 4. Tension Adjustment. 5. Electronic Component Inspection. 6. Belt and Chain Maintenance. 7. Safety Precautions. 8. Professional Servicing. Conclusion....

Introduction. Step 1: Set Up Your Knitting Machine. Step 2: Thread the Yarn. Step 3: Select the Stitch Pattern. Step 4: Load the Yarn. Step 5: Set the Machine Tension. Step 6: Practice and Familiarize Yourself. Step 7: Knit Your Garment. Step 8: Finishing Touches. Conclusion....

Introduction. 1. Unboxing and Inspection. 2. Choosing the Right Location. 3. Assembling the Machine. 4. Connecting Power and Yarn. 5. Familiarizing Yourself with the Controls. 6. Testing and Troubleshooting. 7. Maintenance and Cleaning. 8. Expanding Your Skills. Conclusion....

Introduction. 1. Unboxing and Inspection. 2. Familiarize Yourself with the Manual. 3. Prepare a Suitable Workspace. 4. Assemble the Knitting Machine. 5. Secure the Machine. 6. Thread the Yarn and Spools. 7. Adjust the Tension. 8. Test and Troubleshoot. Conclusion....

Step 1: Unpacking the Machine. Step 2: Assembling the Machine. Step 3: Setting Up the Yarn. Step 4: Adjusting the Machine Settings. Step 5: Loading the Yarn. Step 6: Starting the Knitting Process. Step 7: Troubleshooting. Step 8: Finishing and Maintenance. Conclusion:....

Step 1: Gather Your Materials. Step 2: Attach the Pegs. Step 3: Cast On. Step 4: Create the Foundation Row. Step 5: Knit the Rows. Step 6: Continue Knitting. Step 7: Bind Off. Step 8: Finishing Touches. Conclusion....

1. Understanding the Machine. 2. Selecting the Right Yarn. 3. Preparing the Yarn. 4. Tension Control. 5. Proper Needle Selection. 6. Maintaining the Machine. 7. Planning and Organization. 8. Practice and Patience. Conclusion....

Introduction. Step 1: Unpacking and Inspection. Step 2: Assembling the Machine. Step 3: Connecting Power and Utilities. Step 4: Mounting and Aligning Accessories. Step 5: Programming and Calibration. Step 6: Testing and Troubleshooting. Step 7: Training Operators. Conclusion....

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitti...

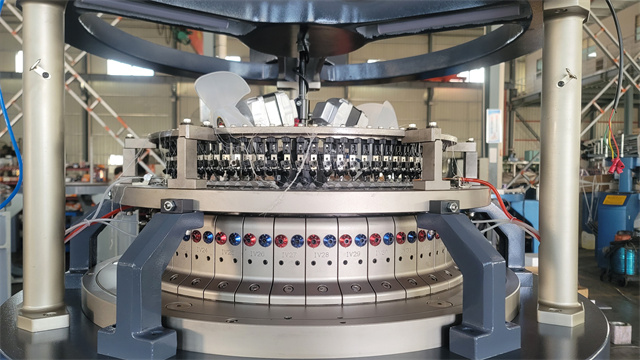

The Double-sided Thread 12-pin to 36-pin Dedicated Interchangeable Knitting Machine is a versatile knitting machine designed to produce double-sided fabrics with high precision and effi...

Terry Jacquard Circular Knitting MachineThe Terry Jacquard Circular Knitting Machine is a cutting-edge textile machinery that revolutionizes the production of terry fabrics with its adv...

Pneumatic High-heel Knitting Machine Features: Pneumatic Control System: Utilizes a pneumatic system for precise control, reducing mechanical wear and improving operational sta...

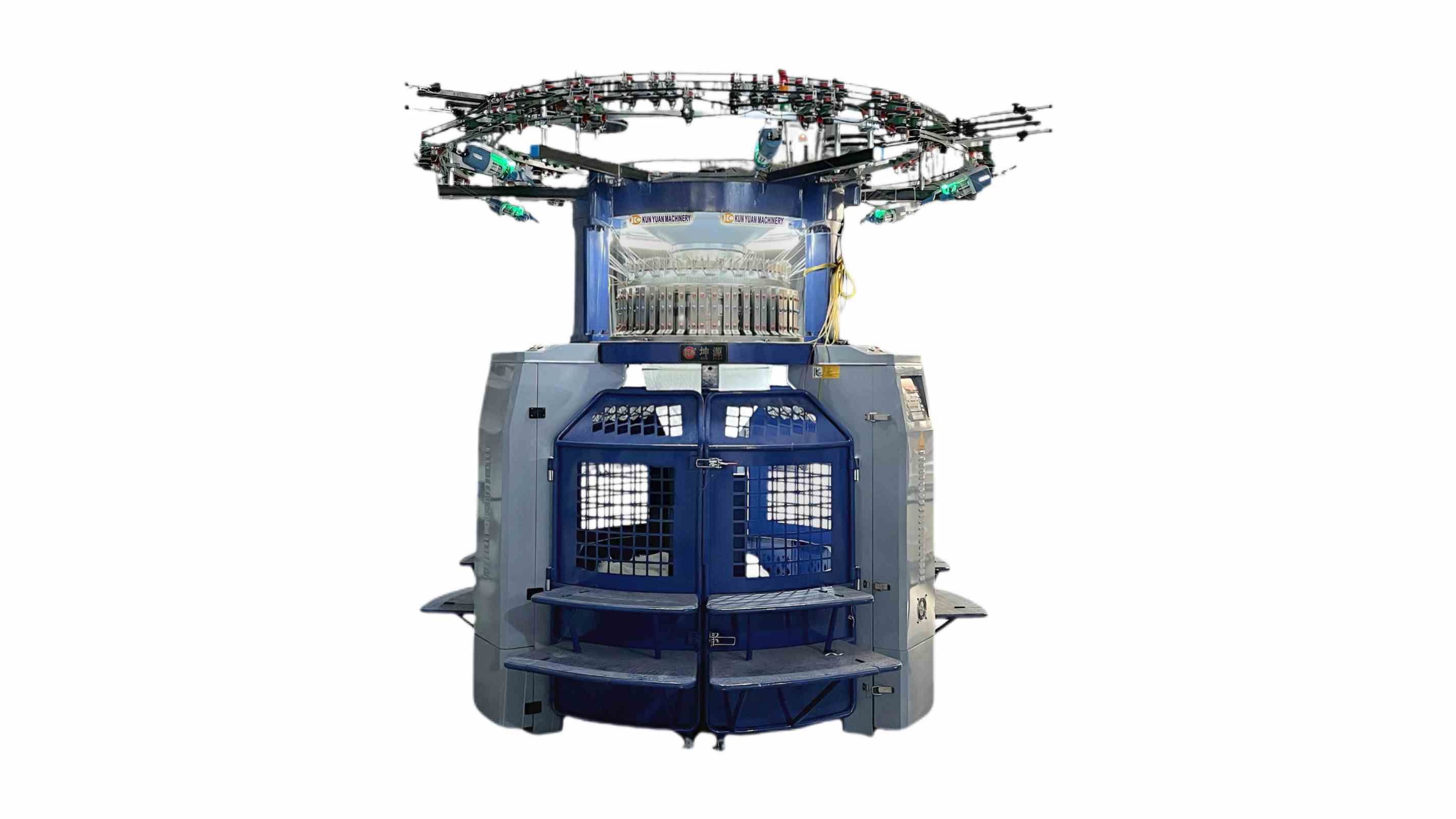

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...