1. Determine Your Requirements. 2. Research Pailung Circular Knitting Machines. 3. Consider Your Budget. 4. Evaluate After-Sales Support. 5. Seek Expert Advice. 6. Compare Prices and Warranty. 7. Purchase from an Authorized Dealer. 8. Make Your Purchase. Conclusion....

1. Consider the Knitting Speed. 2. Evaluate the Number of Knitting Heads. 3. Check the Gauge Options. 4. Review the Software Capabilities. 5. Assess the Yarn Feeding System. 6. Consider Maintenance and Support. 7. Compare Price and Value. 8. Read Customer Reviews. Conclusion....

1. Computerized Controls. 2. Multi-Feeder Systems. 3. Automatic Yarn Changers. 4. Seamless Knitting. 5. High-Speed Performance. 6. Fabric Quality Monitoring. 7. Energy Efficiency. 8. Customization and Flexibility. Conclusion....

1. Advanced Needle Selection System. 2. Multi-Feed Capability. 3. Intelligent Fabric Inspection. 4. Automatic Yarn Tension Control. 5. User-Friendly Interface. 6. Energy-Efficient Design. 7. Versatile Machine Configurations. 8. Remote Monitoring and Control. Conclusion....

1. Determine Your Skill Level. 2. Consider the Machine Size. 3. Research Different Brands. 4. Check the Machine Features. 5. Assess the Material Quality. 6. Consider Your Budget. 7. Seek Recommendations. 8. Test the Machine. Conclusion....

1. Determine Your Needs. 2. Consider Machine Features. 3. Research Different Brands. 4. Set a Budget. 5. Test Before Buying. 6. Check for After-Sales Support. 7. Consider Machine Size. 8. Read and Follow User Manuals. Conclusion....

Introduction. 1. Define Your Requirements. 2. Research Different Brands and Models. 3. Consider Machine Features. 4. Assess Production Capacity. 5. Examine Machine Durability. 6. Consider Cost and Return on Investment. 7. Seek Recommendations and Testimonials. 8. Request Machine Demonstration. Conclusion....

1. Machine Type. 2. Size and Weight. 3. Knitting Capacity. 4. Speed and Efficiency. 5. Durability and Quality. 6. Ease of Use. 7. Additional Features. 8. Price and Warranty. Conclusion....

1. Determine the Purpose. 2. Select the Yarn. 3. Choose the Stitch Pattern. 4. Consider the Fit. 5. Pay Attention to Neckline and Sleeves. 6. Experiment with Colors. 7. Quality and Durability. 8. Take Care Instructions into Account. Conclusion....

1. Determine your knitting needs. 2. Consider the gauge. 3. Evaluate the machine's capabilities. 4. Research different brands and models. 5. Take into account the machine's durability. 6. Test the machine before purchasing. 7. Seek recommendations and advice. 8. Consider the cost. Conclusion....

1. Machine Type. 2. Size and Capacity. 3. Speed and Stitch Variations. 4. Durability and Quality. 5. Ease of Use. 6. Accessories and Attachments. 7. Price. 8. Reviews and Recommendations. Conclusion....

1. Determine your knitting requirements. 2. Research different brands and models. 3. Consider the knitting machine's features. 4. Evaluate the machine's knitting capabilities. 5. Check the machine's durability and maintenance requirements. 6. Compare prices and affordability. 7. Seek demonstrations or try the machines if possibl...

1. Assess Your Production Needs. 2. Research Different Types of Weft Knitting Machines. 3. Consider Machine Features and Specifications. 4. Assess Machine Durability and Reliability. 5. Evaluate After-Sales Support and Service. 6. Consider Cost and Return on Investment. 7. Seek Expert Advice and References. 8. Request Machine De...

Introduction. 1. Determine Your Production Requirements. 2. Consider Machine Specifications. 3. Assess Machine Brands and Suppliers. 4. Evaluate Machine Features. 5. Consider Ease of Use. 6. Evaluate Cost and Return on Investment. 7. Seek Expert Advice. Conclusion....

1. Determine Your Skill Level. 2. Consider Your Budget. 3. Evaluate Machine Specifications. 4. Consider Machine Size and Portability. 5. Research User Reviews and Feedback. 6. Check for Additional Features and Accessories. 7. Seek Expert Advice. 8. Make an Informed Decision. Conclusion....

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for pr...

This machine features a pneumatic opening width system that ensures smooth fabric spreading and rolling, reducing wrinkles and improving fabric quality. Designed for double-sided knitti...

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

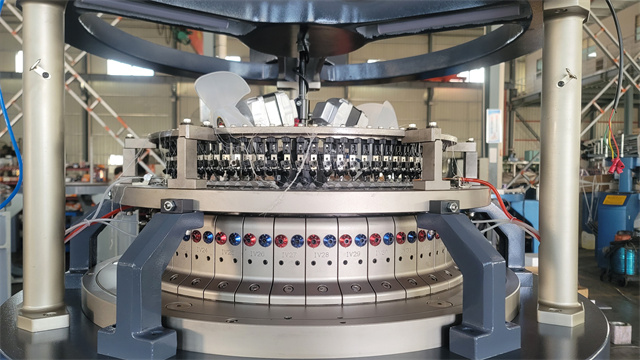

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...