1. Fashion Industry. 2. Sportswear. 3. Automotive Industry. 4. Medical Textiles. 5. Home Furnishings. 6. Technical Textiles. 7. Accessories. 8. Sustainability. Conclusion....

1. Textile Industry. 2. Fashion and Apparel. 3. Automotive Industry. 4. Sports and Outdoor Equipment. 5. Home Furnishings. 6. Medical Textiles. 7. Technical Textiles. 8. Research and Development. Conclusion....

Early Manual Knitting Techniques. Invention of the First Automatic Knitting Machine. Integration of Electronic Controls. Introduction of Computerized Knitting Machines. Advancements in Material Handling and Yarn Control. Incorporation of Seamless Knitting Technology. Transition to Industry 4.0 and Smart Manufacturing. Conclusion...

1. Fashion Industry. 2. Sports Apparel. 3. Uniform Manufacturing. 4. Children's Apparel. 5. Luxury Knitwear. 6. Eco-Friendly Production. 7. Small-Scale Production. 8. Custom Knitwear. Conclusion....

1. Increased Efficiency. 2. Precision and Consistency. 3. Versatility in Design. 4. Time and Cost Savings. 5. Enhanced Productivity. 6. Improved Quality Control. 7. Sustainable and Environmentally Friendly. 8. Innovation and Adaptability. Conclusion....

Improved Efficiency. Versatility in Design. Enhanced Comfort and Fit. Cost Efficiency. Increased Durability. Reduced Environmental Impact. Greater Customization. Improved Profitability. Conclusion....

Advantages of Underwear Knitting Machines. 2. Versatile Fabric Options. 3. Customization Capabilities. 4. Seamless Integration of Features. 5. Waste Reduction. Production Process of Underwear Knitting Machines. 7. Automated Knitting Process. 8. Finishing and Quality Control. Conclusion....

Advantages of Towel Knitting Machine. Enhanced Productivity and Efficiency. Precise Yarn Control. Customization and Personalization. Efficient Resource Utilization. Production Process of Towel Knitting Machine. Conclusion....

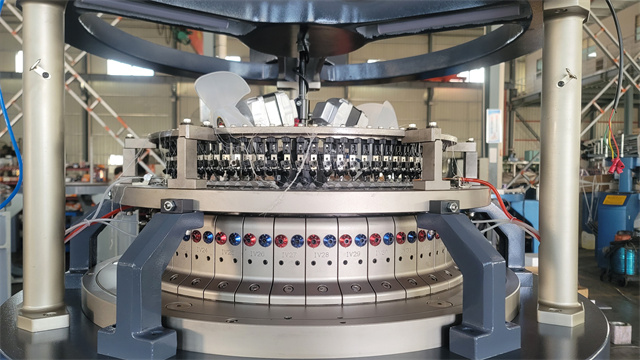

Advantages of Single Circular Knitting Machine. High Efficiency and Productivity. Flexibility in Design and Fabrication. Cost-Effectiveness and Reduced Wastage. Production Process of Single Circular Knitting Machine. Knitting Mechanism. Fabric Inspection and Quality Control. Finishing and Packaging. Conclusion....

Early Innovations. Mechanization and Industrialization. Introduction of Circular Sinker Technology. Integration of Computerized Controls. Advancements in Material Handling. Efficiency and Sustainability Focus. Industry 4.0 Integration. Conclusion....

Advantages of Needle Circular Knitting Machine. Increased Productivity. Fabric Diversity. Cost-Efficiency. Technical Innovation. Environmental Sustainability. Customization Capabilities. Quality Assurance. Conclusion....

Advantages of Interlock Circular Knitting Machine. High Productivity and Efficiency. Quality of Fabrics Produced. Energy Efficiency and Sustainability. Flexibility in Design and Pattern Creation. Production Process of Interlock Circular Knitting Machine. Conclusion....

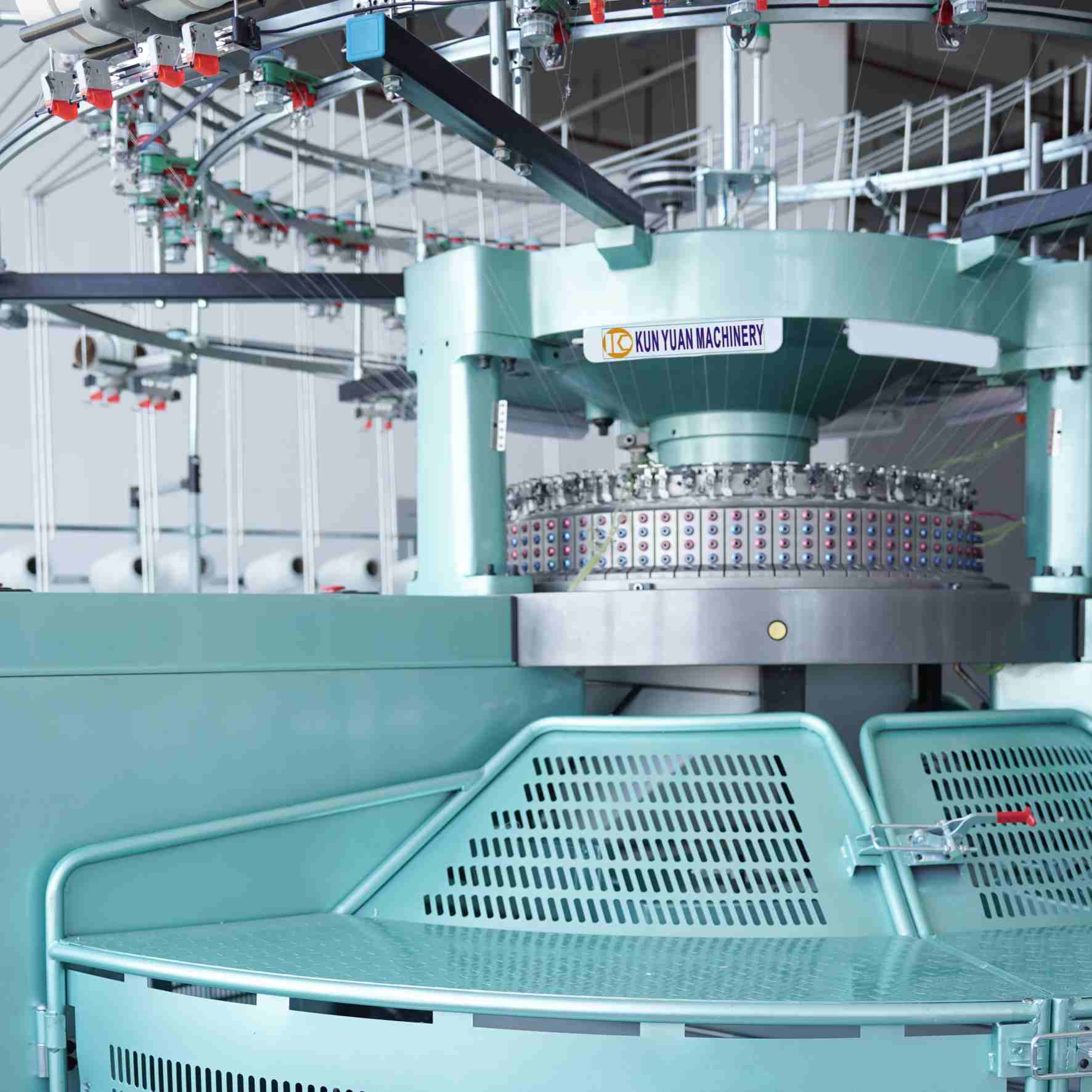

Advanced Technology. Versatile Production Capabilities. Efficient Output Efficiency. Energy and Resource Savings. Intuitive Operation and Maintenance. Quality Control and Consistency. Adaptability to Different Yarns and Fibers. Integration with Industry 4.0....

The Early Beginnings. The Introduction of Automation. Advancements in Material Handling. Integration of Computerized Systems. Enhanced Production Speed and Efficiency. Incorporation of Sustainable Practices. Expanding Design Possibilities. Conclusion. ...

Early Hand-Knitting Needles. Introduction of Metal Needles. Development of Needle Coatings. Incorporation of Needle Design Technologies. Integration of Electronic Needle Control Systems. Adoption of Circular Knitting Machine Needles with Enhanced Materials. Introduction of Smart Needles with Sensor Technology. Future Trends in C...

Three Thread Fleece Circular Knitting Machine Product Description: The Three Thread Fleece Circular Knitting Machine is a versatile and efficient knitting machine designed specifi...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge...

The High Pile Cutting Circular Knitting Machine is a state-of-the-art textile manufacturing equipment designed for producing high-pile fabrics with precision and efficiency. This machin...

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...

The Double-Sided Thread Interchangeable Circular Knitting Machine is a cutting-edge textile machine designed to produce high-quality, double-sided knitted fabrics with the ability to ...