1. Garment Production. 2. Accessory Design. 3. Home Decor. 4. Artistic Creations. 5. Fashion Design. 6. Educational Tool. 7. Therapeutic Benefits. 8. Small Business Opportunities. ...

1. Fashion Industry. 2. Sportswear Manufacturing. 3. Medical Textiles. 4. Home Textiles. 5. Automotive Industry. 6. Technical Textiles. 7. Footwear Industry. 8. Sustainable Fashion...

1. Introduction. 2. High-Speed Performance. 3. Precision and Versatility. 4. Energy Efficiency. 5. User-Friendly Interface. 6. Durability and Reliability. 7. Impact on the Textile ...

1. Introduction to the Auto Striper Circular Knitting Machine. 2. Features and Functionality. 3. Advantages of the Auto Striper Circular Knitting Machine. 4. Applications in the Te...

Introduction. 1. Creating Complex Patterns. 2. Seamless Garment Production. 3. Increased Efficiency. 4. Versatile Fabric Options. 5. Reduced Waste. 6. Automation and Technology Int...

Introduction. 1. Seamless Construction. 2. Customization and Unique Designs. 3. Efficiency and Speed. 4. Versatility in Material Choices. 5. Sustainable Manufacturing. 6. Comfort a...

1. Apparel Industry. 2. Home Textiles. 3. Automotive Industry. 4. Sports and Activewear. 5. Medical Textiles. 6. Technical Textiles. 7. Fashion Accessories. 8. Research and Develop...

Introduction. 1. Enhanced Design Flexibility. 2. Efficient Production Process. 3. Seamless Comfort and Fit. 4. Customization and Personalization. 5. Sustainable Production. 6. Inno...

The Evolution of Rib Circular Knitting Machine Introduction The rib circular knitting machine has undergone significant evolution over the years, revolutionizing the textile ind...

One of the most significant advancements in the textile industry is the evolution of the Terry Jacquard Circular Knitting Machine. This innovative piece of equipment has revolutio...

1. The Birth of Circular Knitting Machines. 2. Technological Advancements: Cast-Iron to High-Strength Alloys. 3. On-the-Fly Pattern Changes. 4. Automation and Digitization. 5. Vers...

The Early Origins. Mechanization and Automation. Technological Innovations. Enhanced Versatility. Efficiency and Sustainability. Digital Integration. Quality and Consistency. The F...

Early Developments. Introduction of Circular Knitting Machines. Integration of Jacquard Technology. Advancements in Automation. Innovations in Fabric Quality. Versatility and Produ...

Early Manual Designs. Introduction of Automation. Adoption of Electronic Controls. Integration of Computer Technology. Enhancements in Material Handling. Focus on Sustainable Pract...

Early Development. Mechanical Innovations. Technological Integration. Material Adaptability. Sustainability Initiatives. Automation and Industry 4.0. Global Impact. Conclusion....

The Origins of Circular Knitting. Early Circular Knitting Machines. The Introduction of Automated Circular Knitting Machines. Advancements in Technology. Specialized Circular Knitt...

Early Developments of Circular Knitting Machines. The Industrial Revolution and Advancements in Circular Knitting. Innovative Technology in Modern Circular Knitting Machines. Appli...

Introduction. 1. Machine Capacity. 2. Machine Speed. 3. Machine Versatility. 4. Machine Durability. 5. Machine Technology. 6. Machine After-Sales Support. 7. Machine Cost. Conclusi...

Introduction. 1. Fabric Type. 2. Production Capacity. 3. Machine Features. 4. Budget. 5. After-Sales Support. 6. Reviews and Recommendations. 7. Consider Future Expansion. 8. Compa...

Introduction. 1. Machine Type. 2. Machine Gauge. 3. Machine Diameter. 4. Speed and Productivity. 5. Additional Features. 6. Machine Reliability and Support. 7. Cost and Budget. 8. ...

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

This machine is engineered for precision knitting of high-density threaded fabrics, particularly for garment components such as collars, cuffs, and waistbands. The 60-gauge configuration provides an ultra-...

A knitting machine works by using hooks or needles to form loops of yarn in a specific pattern. The machine can be operated manually or programmed to follow a predetermined design....

A knitting machine is a mechanical or electronic device that automates the process of creating knitted fabric, allowing for faster and more efficient production of knitted items....

Key Features: 32-Inch Diameter: The 32-inch diameter allows for large production volumes, making it ideal for manufacturing sweatshirts, hoodies, and other casual wear. Prov...

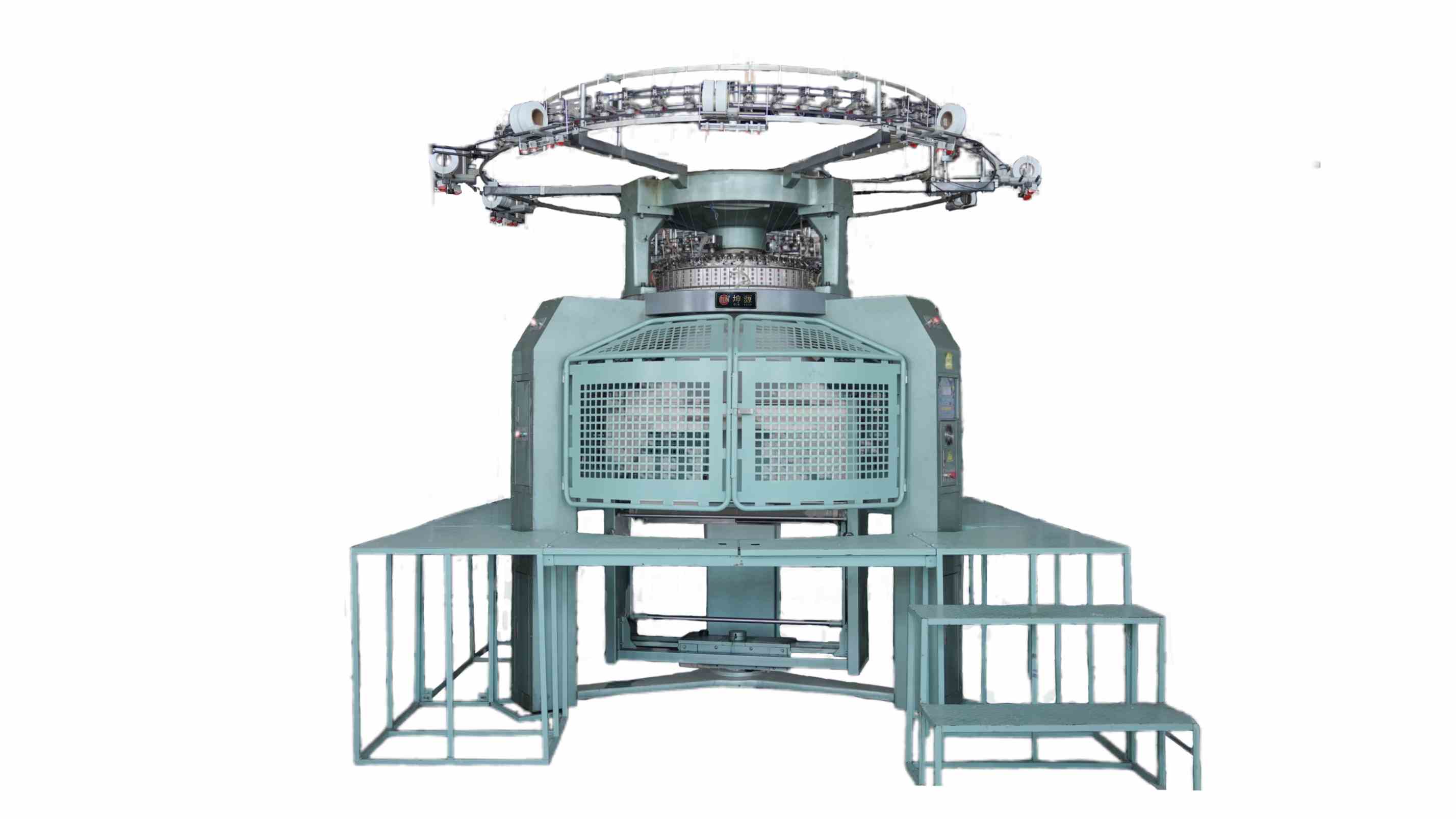

The Pneumatic Double-side High Foot Opening Circular Knitting Machine is an advanced knitting equipment designed for high-efficiency fabric production. It integrates pneumatic control...