Introduction. 1. Knitwear Manufacturing. 2. Sportswear Production. 3. Home Textiles. 4. Accessories. 5. Medical Textiles. 6. Automotive Textiles. 7. Technical Textiles. 8. Customiz...

1. Apparel Industry. 2. Sportswear and Activewear. 3. Home Textiles. 4. Automotive Industry. 5. Medical Textiles. 6. Technical Textiles. 7. Footwear Manufacturing. 8. Accessories a...

1. Production of Basic Knitted Fabrics. 2. Seamless Garment Production. 3. Elastic and Stretch Fabrics. 4. Textured and Patterned Fabrics. 5. Jacquard and Intarsia Knitting. 6. Sam...

1. Apparel Industry. 2. Sportswear Manufacturing. 3. Home Textiles. 4. Medical Textiles. 5. Automotive Industry. 6. Technical Textiles. 7. Fashion Accessories. 8. Upholstery. Concl...

1. Textile Industry. 2. Fashion Industry. 3. Medical Textiles. 4. Automotive Industry. 5. Home Furnishings. 6. Sports Industry. 7. Technical Textiles. 8. Non-textile Applications. ...

1. Textile Industry. 2. Fashion and Apparel. 3. Automotive Industry. 4. Sports and Outdoor Equipment. 5. Home Furnishings. 6. Medical Textiles. 7. Technical Textiles. 8. Research a...

Improved Efficiency. Versatility in Design. Enhanced Comfort and Fit. Cost Efficiency. Increased Durability. Reduced Environmental Impact. Greater Customization. Improved Profitabi...

Advantages of Single Circular Knitting Machine. High Efficiency and Productivity. Flexibility in Design and Fabrication. Cost-Effectiveness and Reduced Wastage. Production Process ...

Early Innovations. Mechanization and Industrialization. Introduction of Circular Sinker Technology. Integration of Computerized Controls. Advancements in Material Handling. Efficie...

Advantages of Needle Circular Knitting Machine. Increased Productivity. Fabric Diversity. Cost-Efficiency. Technical Innovation. Environmental Sustainability. Customization Capabil...

Advantages of Interlock Circular Knitting Machine. High Productivity and Efficiency. Quality of Fabrics Produced. Energy Efficiency and Sustainability. Flexibility in Design and Pa...

Advanced Technology. Versatile Production Capabilities. Efficient Output Efficiency. Energy and Resource Savings. Intuitive Operation and Maintenance. Quality Control and Consisten...

The Early Beginnings. The Introduction of Automation. Advancements in Material Handling. Integration of Computerized Systems. Enhanced Production Speed and Efficiency. Incorporatio...

Early Hand-Knitting Needles. Introduction of Metal Needles. Development of Needle Coatings. Incorporation of Needle Design Technologies. Integration of Electronic Needle Control Sy...

Advantages of Double Circular Knitting Machine. High Production Efficiency. Economical Use of Yarn. Flexible Fabric Design. Advanced Technology Integration. Energy Efficiency. Auto...

1. Versatility in Design. 2. Enhanced Comfort and Fit. 3. Reduced Production Time. 4. Cost-Effective Manufacturing. 5. Seamless Integration of Features. 6. Environmentally Friendly...

1. Read the Care Instructions. 2. Hand Wash or Use a Delicate Cycle. 3. Use Cold Water. 4. Dry Flat. 5. Avoid Direct Sunlight and Heat. 6. Never Use an Iron. 7. Store Properly. 8. ...

Advantages of Circular Knitting Machine Needles. Durability and Precision. Specialized Needle Designs. Efficient Yarn Handling. Production Process of Circular Knitting Machine Need...

Advantages of Circular Knitting Machine. High Production Efficiency. Versatility and Flexibility. Cost-Effectiveness. Quality and Consistency. Production Process of Circular Knitti...

Advantages of Body Size Circular Knitting Machine. High Production Efficiency. Versatility in Fabric Production. Reduced Material Wastage. Quality Control and Consistency. Advanced...

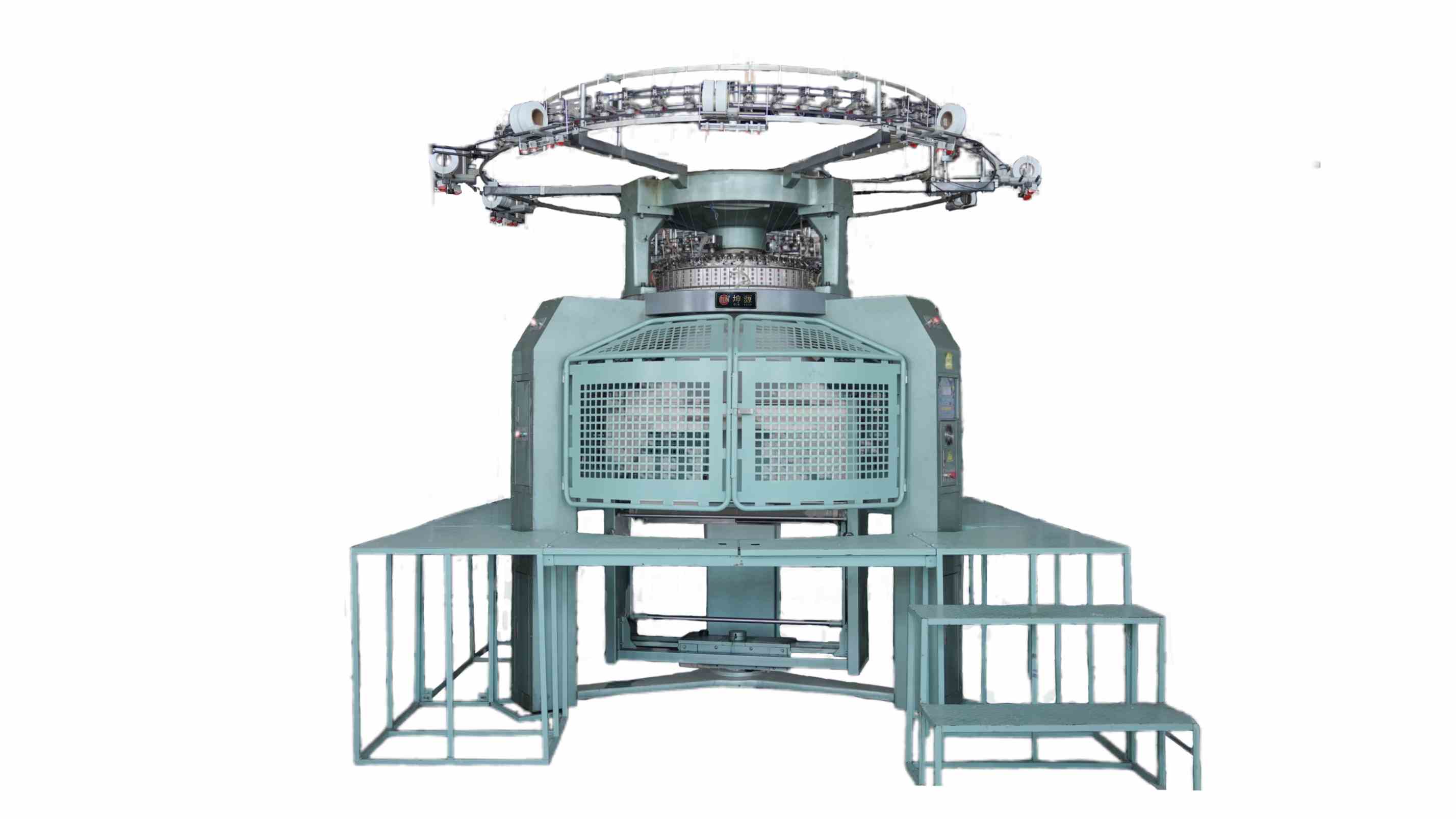

The Double Jacquard Circular Knitting Machine is a state-of-the-art knitting machine that combines advanced technology with superior design. This machine is specifically designed for producing intricate an...

This machine is engineered for high-quality production of double-sided knitted fabrics, especially suited for school uniform textiles and other durable, functional fabrics. The 28-gauge needle system balan...

This machine is engineered for precision knitting of high-density threaded fabrics, particularly for garment components such as collars, cuffs, and waistbands. The 60-gauge configuration provides an ultra-...

The portability of knitting machines varies depending on their size and weight. Some compact models are designed for easy transport, while larger industrial machines are generally stati...

The cost of knitting machines can vary significantly depending on the brand, model, and features. Entry-level machines for hobbyists can range from $100 to $500, while industrial-grade ...

The 36-Inch 32G 108F Double-Sided Knitting Machine is a state-of-the-art textile machine designed for high-quality, double-sided knitted fabric production. This machine is ideal for p...

A Pneumatic Double-side High Foot Opening Knitting Machine typically refers to an advanced knitting machine designed for producing knitted fabrics with specific features like high foot ...